Phase calibration structure of magnetic resonance radio frequency power amplifier

A radio frequency power and phase calibration technology, applied to power amplifiers, high-frequency amplifiers, improved amplifiers to improve efficiency, etc., can solve problems such as difficulty in ensuring consistency, deviation between output results and expected design results, and high power, to achieve Best synthesis efficiency, phase consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

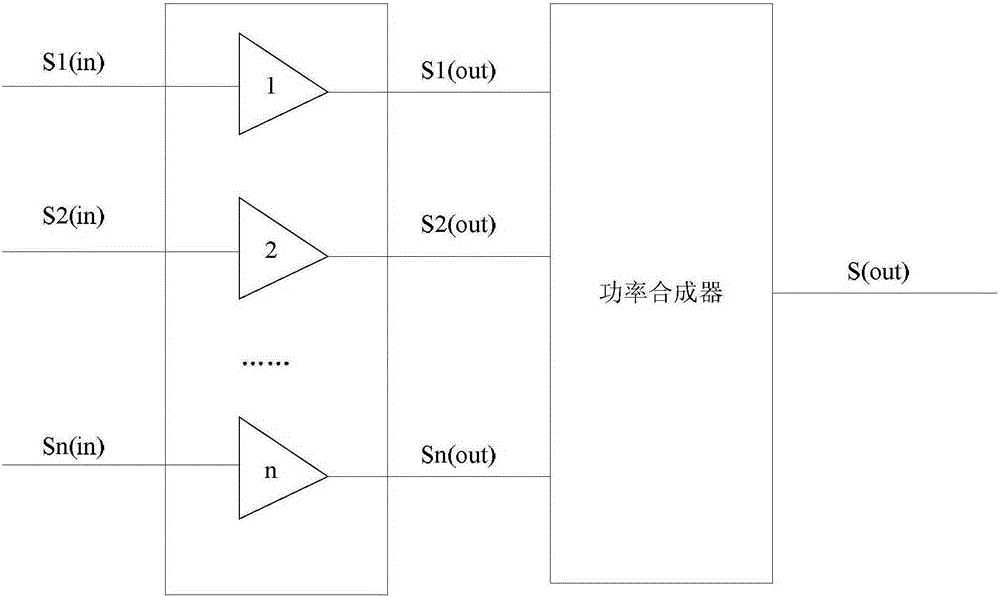

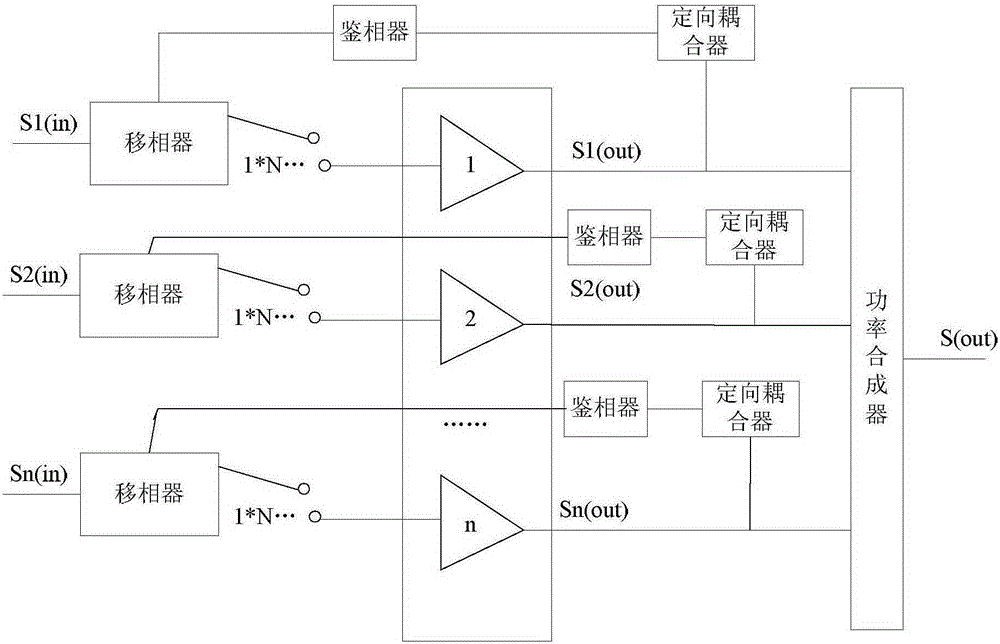

[0011] Such as figure 2 A phase alignment structure of a magnetic resonance radio frequency power amplifier shown, wherein the magnetic resonance radio frequency power amplifier includes a power amplification module of N power amplifier tubes, and a power combining module for inputting signals S1 (in), S2 of N paths (in), ... Sn(in) for power amplification and synthesis, the phase calibration structure includes: N switch matrix phase shifters with N output positions, N phase detectors and N directional couplers, N Among the input signals, each input signal is connected to a phase shifter and then connected to the input end of a power amplifier tube in the power amplifier module, and the output end of the power amplifier tube is connected to the input end of a directional coupler, and the directional coupler The output end of the phase detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com