Series connection and parallel connection methods of series motor stator winding

A technology for motor stator and stator winding, which is applied in the shape/style/structure of winding conductors, electric components, and the manufacture of motor generators, etc. It can solve the problems of inconsistent mechanical properties, inability to connect motors in series, and achieve consistent mechanical properties. , load distribution balance, the effect of reducing radial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

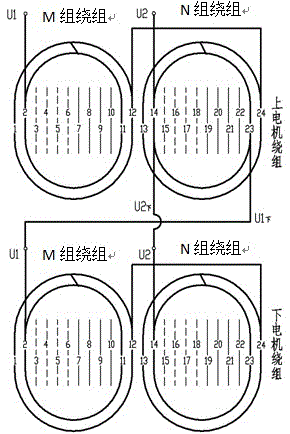

[0024] The two submersible motors connected in series realize the connection of the upper and lower motor shafts in a certain way in terms of mechanical structure, and the stator windings of the upper and lower submersible motors are connected in a special series connection. The serial expansion diagram of the stator windings of the upper and lower submersible motors is as follows: figure 1 shown.

[0025] When the upper and lower motors are connected in series, and the three-phase windings are connected in series in a star (Y-shape), when the stator winding of the upper motor is wound, each wire slot of the M group of winding wires is wound enough for the designed number of coil turns. , followed by winding the N groups of winding wires of the motor stator, among the N groups of winding wires, there is only one specially designated wire slot k (for example, the 14th wire slot in this embodiment), the number of winding turns in the ratio of the designed number of turns One le...

Embodiment 2

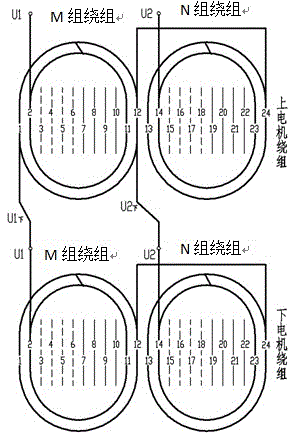

[0027] The two submersible motors connected in series realize the connection of the upper and lower motor shafts in a certain way in terms of mechanical structure, and the stator windings of the upper and lower submersible motors are connected in a special series connection. The serial expansion diagram of the stator windings of the upper and lower submersible motors is as follows: figure 2 shown.

[0028] When the upper and lower motors are connected in series and the three-phase windings are connected in delta (△) in series, there is only one specially designated slot q in the M groups of winding wires in the stator winding of the upper motor (for example, the 12th wire in the embodiment Slot) is less than the designed number of winding turns, and the remaining wire slots in the M group of winding wires are wound according to the designed number of turns. When the M group of winding wires in the stator winding of the upper motor are wound, the winding wires are led to the l...

Embodiment 3

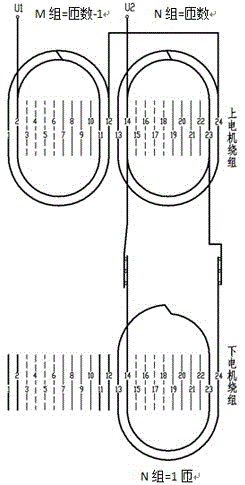

[0030] The two submersible motors connected in series realize the connection of the upper and lower motor shafts in a certain way in terms of mechanical structure, and the stator windings of the upper and lower submersible motors are connected in a special parallel manner. The parallel expansion diagram of the stator windings of the upper and lower submersible motors is as follows: image 3 and Figure 4 shown.

[0031] When two submersible motors are connected in series up and down, a special winding method is adopted when the stator windings of the two motors are connected in parallel, and the M group of winding wires and the N group of winding wires in the stator windings of the upper and lower motors are exchanged for one turn, that is, the upper The winding wires of group M of the motor are wound one less turn, and the coil of this turn is moved to the winding wires of group N of the lower motor, and the winding wires of group N of the lower motor are wound one less turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com