Ink jetting device of press machine

A technology of inkjet devices and presses, which is applied in the direction of spraying devices, etc., can solve problems such as the inability to guarantee the consistency of workers, the oxidation shell is not blown clean, and the unfavorable operation of workers, so as to save labor costs, reduce labor costs, and reduce work volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

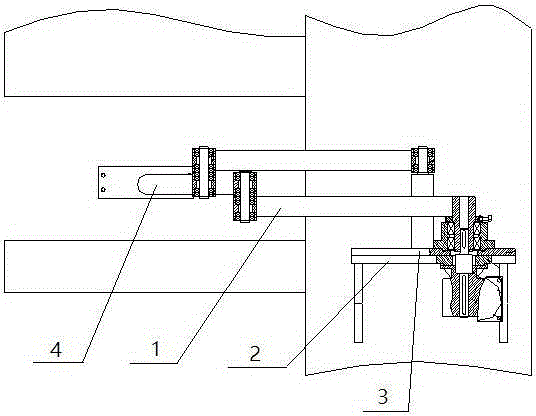

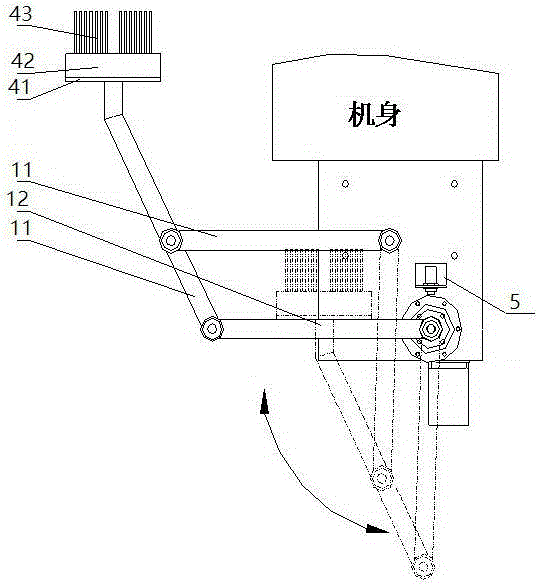

[0023] Example :Such as figure 1 and figure 2 As shown, an inkjet device of a press includes a moving part fixed on the body of the press, and an inkjet part connected with the moving part; wherein the inkjet part is connected to the The cavity inside the press is sprayed. The moving device is a link mechanism 1 installed on the press body.

[0024] The linkage mechanism 1 is installed on the press body in this way: firstly, an installation base 2 is installed on the press body, and the installation base 2 can be fixed on the press body by studs , it can also be directly welded on the press body. In this embodiment, the installation base 1 is welded vertically to the press body through two sheet metal parts, and then the installation A bottom plate 2 is arranged on the base 1, and the bottom plate is fixed on the installation base 1 by screws, and finally the linkage mechanism 1 is installed on the bottom plate 2.

[0025] The linkage mechanism 1 is a parallelogram four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com