Comb-type sorting equipment

A comb-type and sorting technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems affecting the production of inlaid drip irrigation belts, increase the input of labor costs, and occupy the production space of the workshop, and achieve a simple structure, The effect of improving separation speed and efficiency and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0036] The present invention will be described in detail below with reference to the accompanying drawings and examples.

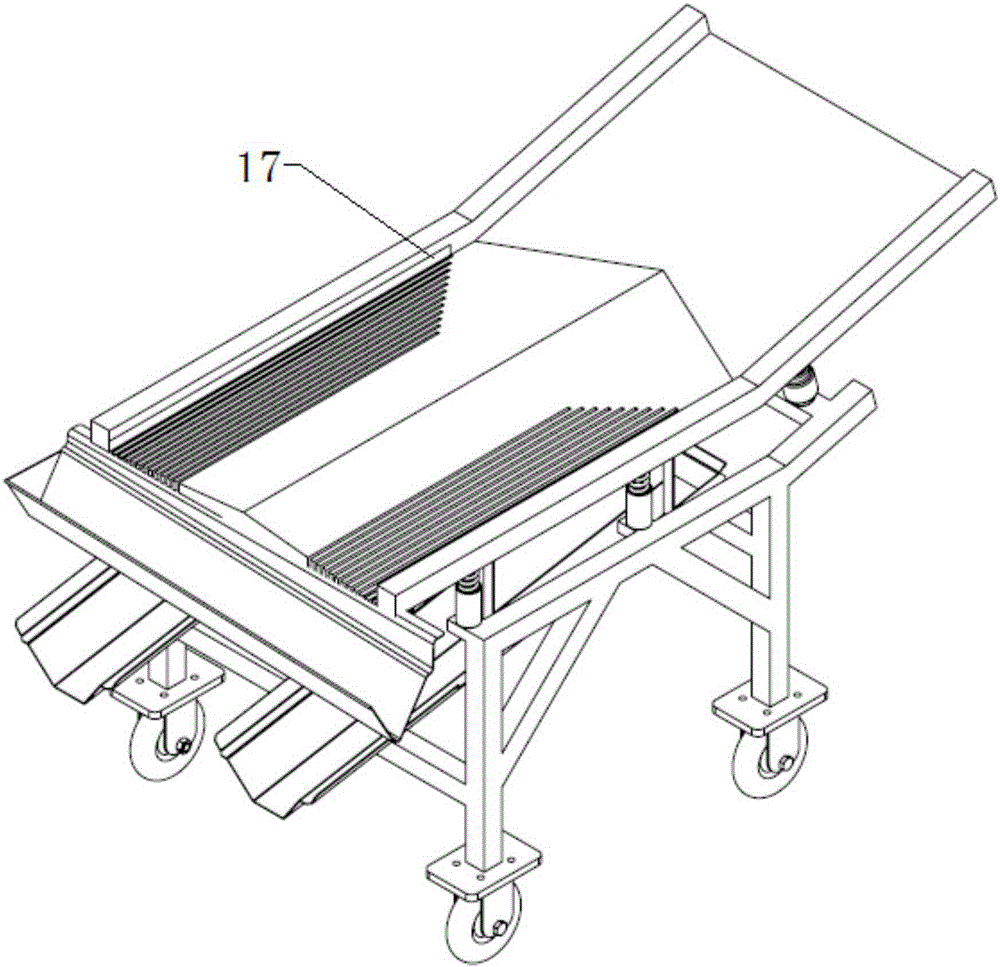

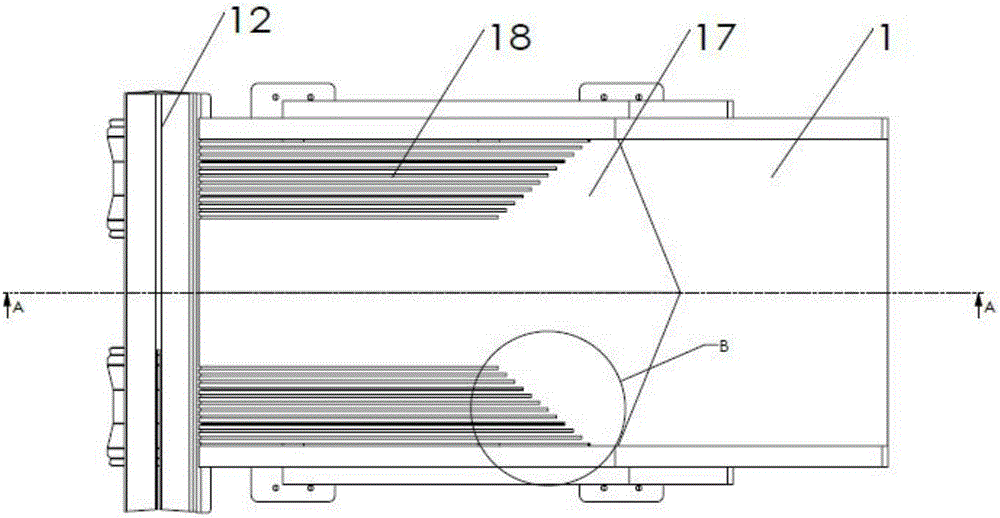

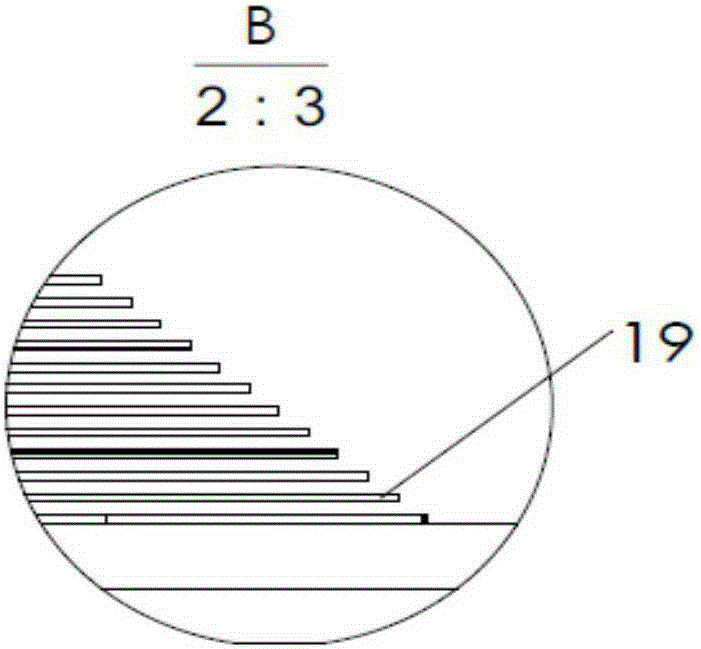

[0037] A comb-type sorting device, including a sieve plate 1, a vibration source and a support 2, the sieve plate 1 is fixed to the support 2 through a first elastic member, and a dripper is connected to the bottom of the sieve plate 1 through a fixing piece Conveyor trough 13, the end of the sieve plate 1 is provided with a handle conveying trough 12, the vibration source drives the sieve plate 1, the dripper conveying trough 13 and the feed handle conveying trough 12 to vibrate, the sieve plate 1 is provided with a comb-shaped area 18, and the comb-shaped area 18 is provided with a number of elongated first guide slots 19 arranged in parallel. Parallel, the central axis of the handle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com