Valve cover bolt hole lost mould and direct molding process thereof

A molding process and lost foam technology, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problems of uneven wall thickness of the bolt table, affecting the appearance, and high cost, so as to reduce labor intensity and technical difficulty. Reduced processing cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

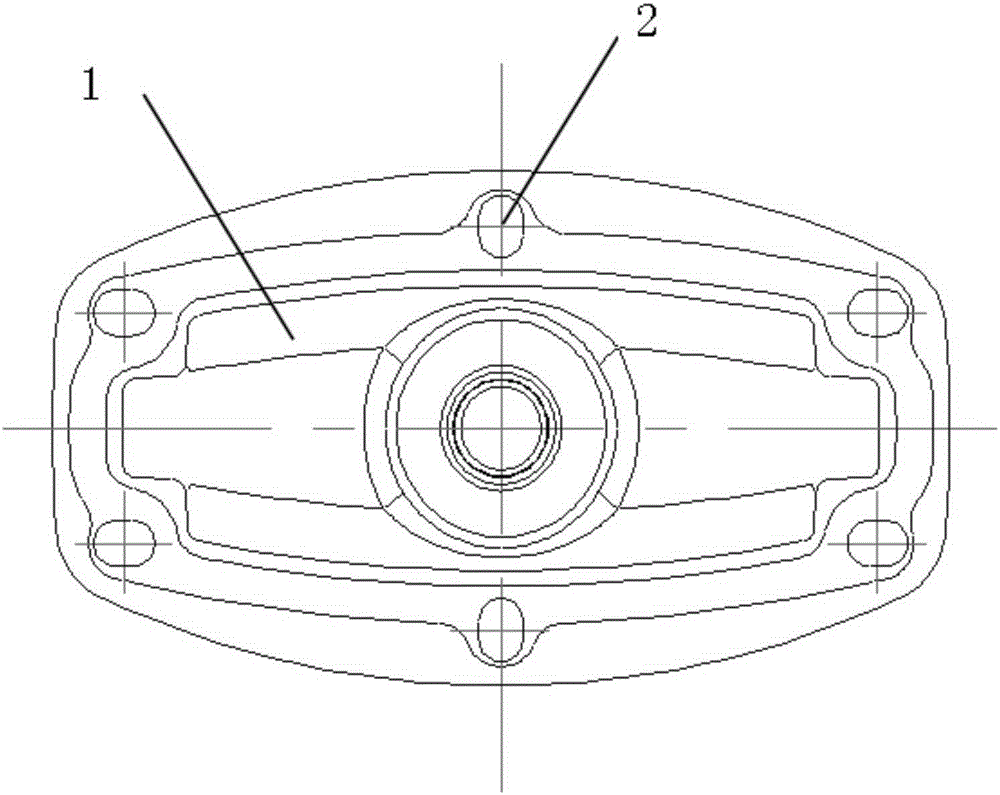

[0035] figure 1 Show the specific embodiment of the present invention: a bonnet bolt hole lost foam, including bonnet lost foam 1 and bolt holes 2, the bolt holes 2 are waist-shaped holes, bolt holes 2 are located in the bonnet lost foam 1, and the long side of the waist-shaped hole is arranged horizontally, the long side of the waist-shaped hole on both sides of the lost foam 1 of the valve cover is arranged vertically, and the wall thickness of the bolt hole 2 is 3mm, and the bolt hole 2 position accuracy is ±0.25mm.

[0036] In order to meet the requirement that the position of the bolt hole 2 is ±0.25mm, this requirement is not a problem for machining, but it is very strict for casting, so the bolt hole 2 is changed into a waist hole, which can effectively avoid the influence of casting shrinkage. Without reducing the installation accuracy, at the same time, the original machining is to process 6 round holes, which has the phenomenon of over-constraint. The bolt hole 2 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com