Rough machining equipment for ceramic tiles

A ceramic tile and equipment technology, which is applied in the direction of metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of low efficiency, inability to effectively adapt to the polishing of glazed tiles, large grinding volume, etc., and reach the contact area Small, small transmission impact, high grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

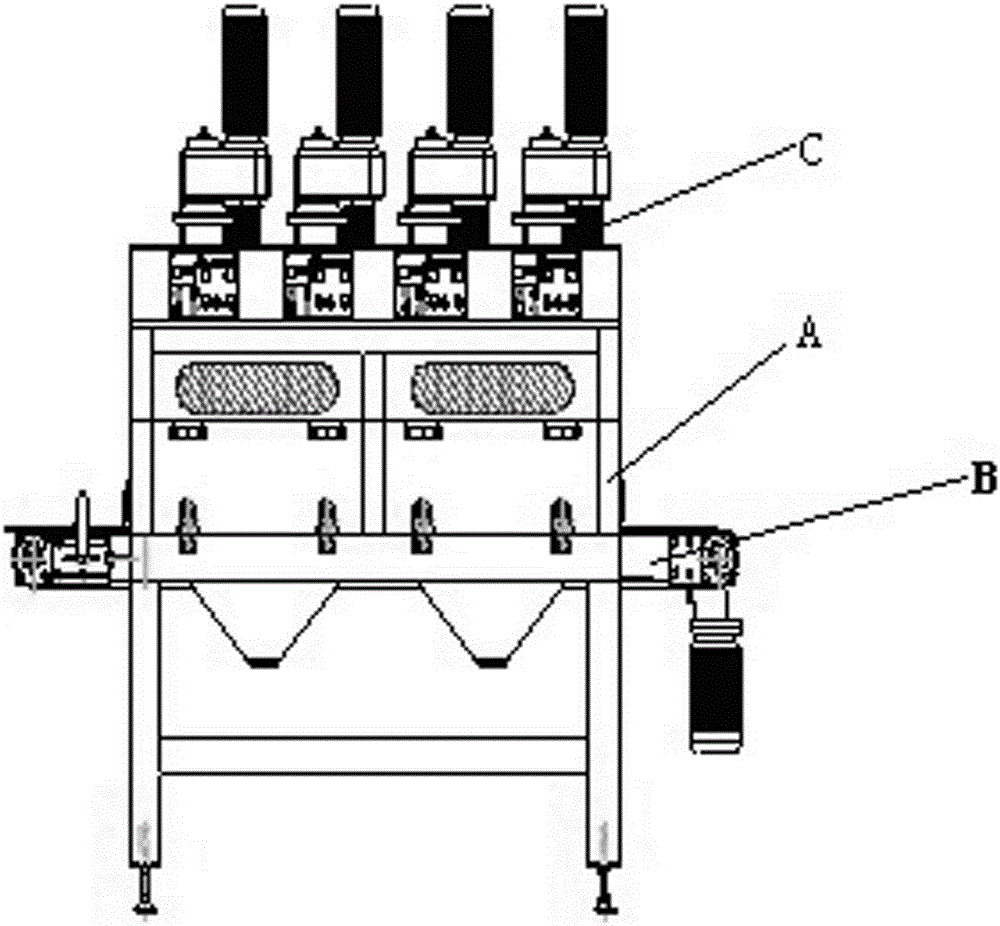

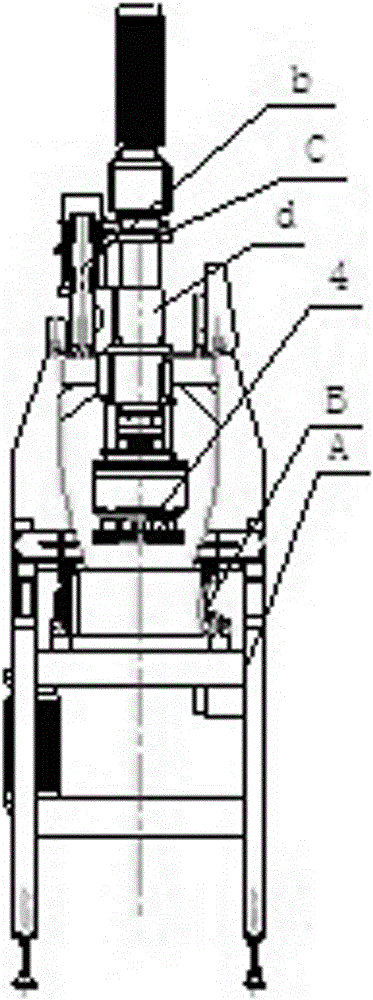

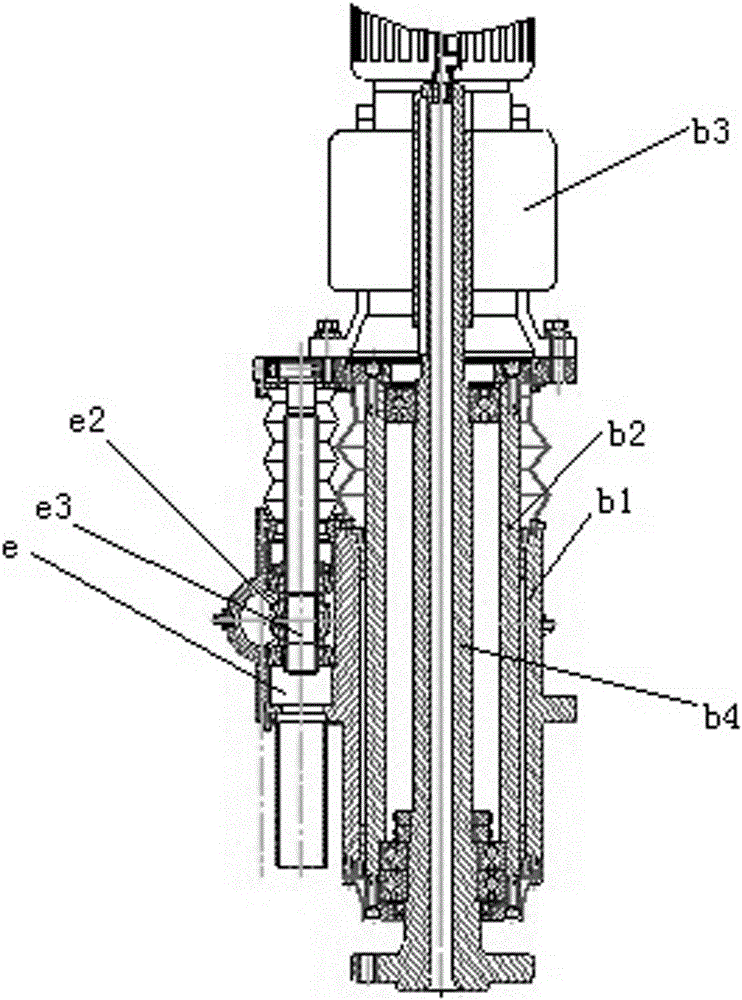

[0014] like figure 1 , 2 As shown, this includes a frame A, a tile transmission mechanism B set on the frame A, a polishing assembly C set on the frame A and above the tile transmission mechanism B, and the special feature is that the polishing assembly C includes Power transmission component b, grinding disc component d, such as image 3 , 4 As shown, the power transmission component b includes the sleeve b1 fixed on the frame A, the sleeve b2 slidably arranged in the sleeve b1, the transmission shaft b4 driven by the motor b3 in the sleeve b2, and the transmission shaft b4 set in the sleeve b2. The power mechanism e on the outside of the cylinder b1 drives the shaft sleeve b1 to move up and down, and the grinding disc component d includes the base 1 connected with the shaft sleeve b1, the main shaft 3 installed on the base 1 through the rotation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com