A kind of preparation method of carbon nitride nanotube

A nanotube and carbon nitride technology is applied in the field of preparation of nanotubular carbon nitride materials, which can solve the problems of large size and high dependence of carbon nitride nanotubes, achieve uniform size, low cost, and overcome complex preparation procedures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

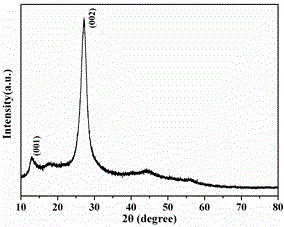

Image

Examples

Embodiment 1

[0042] 1.1 Make a solution of 50mL ethanol and 5mL water, add 1.5mL ammonia water, stir for 30min to get a uniform solution;

[0043] 1.2 Add 0.4 mL tetraethyl orthosilicate (TEOS) to the above solution and stir for 2 h to obtain the silica nanosphere template product;

[0044] 1.3 Centrifuge, wash and dry the product obtained above, disperse it into 10 mL of water, add 1 μL (3-mercaptopropyl)trimethoxysilane (MPS) and stir for 2 days, then centrifuge and wash to obtain the product;

[0045] 1.4 Take 0.1g of the product solid powder obtained in the above step 1.3, disperse it into 20mL of water, add 1.0g of melamine, stir for 12 hours, centrifuge, wash and dry to obtain a white solid powder, and put the white solid powder under the protection of an inert gas 1. Heating to 550°C at a heating rate of 5°C / min, keeping the temperature for 2 hours to completely decompose the melamine, and then cooling naturally to obtain the carbon nitride-coated silica nanosphere material;

[004...

Embodiment 2

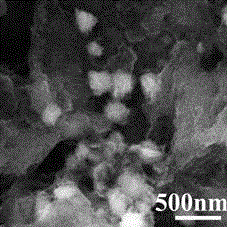

[0049] The preparation method is the same as in Example 1, except that after being immersed in 10% hydrofluoric acid solution, the stirring time is 1h. The resulting product appearance is substantially the same as in Example 1, but there is a small amount of SiO 2 The balls are not etched away. Figure 4 It is a scanning electron microscope photo of the etched sample. It can be seen from the figure that the outer diameter of the carbon nitride nanotube is 67-180 nm, the length is 65 nm-250 nm, and the surface is smooth.

Embodiment 3

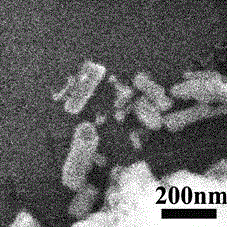

[0051] The preparation method is the same as in Example 1, except that the amount of TEOS added is 1 mL. The morphology of the obtained nanotubular graphitic carbon nitride is the same as that of Example 1. Figure 5 It is a scanning electron microscope photo of the sample. It can be seen from the figure that the outer diameter of carbon nitride nanotubes is 80~200nm, the length is 65 nm~1.15μm, and the surface is smooth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com