Method of cultivating chlorella by using brewery industry wastewater

A technology for brewing wastewater and industrial wastewater, applied in the direction of unicellular algae, can solve the problems of large aeration power consumption, waste of resources, sludge and other problems, and achieve the effect of high economic and social comprehensive benefits and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Pretreatment of beer wastewater: Sampling at the entrance of the brewery sewage treatment tank, which belongs to mixed wastewater. After the beer wastewater is retrieved, it is heated and boiled for 5 minutes, filtered with multi-layer gauze, cooled and stored in a sealed environment at 3°C;

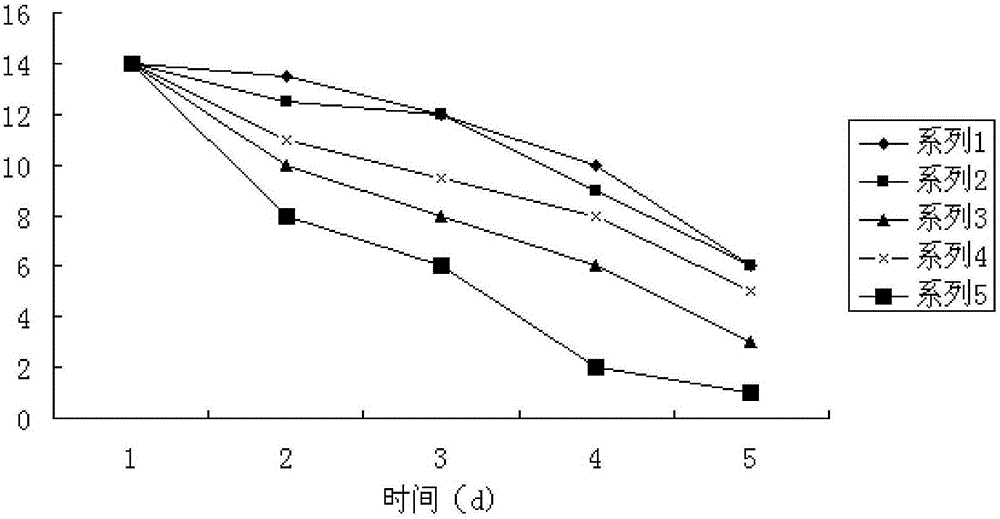

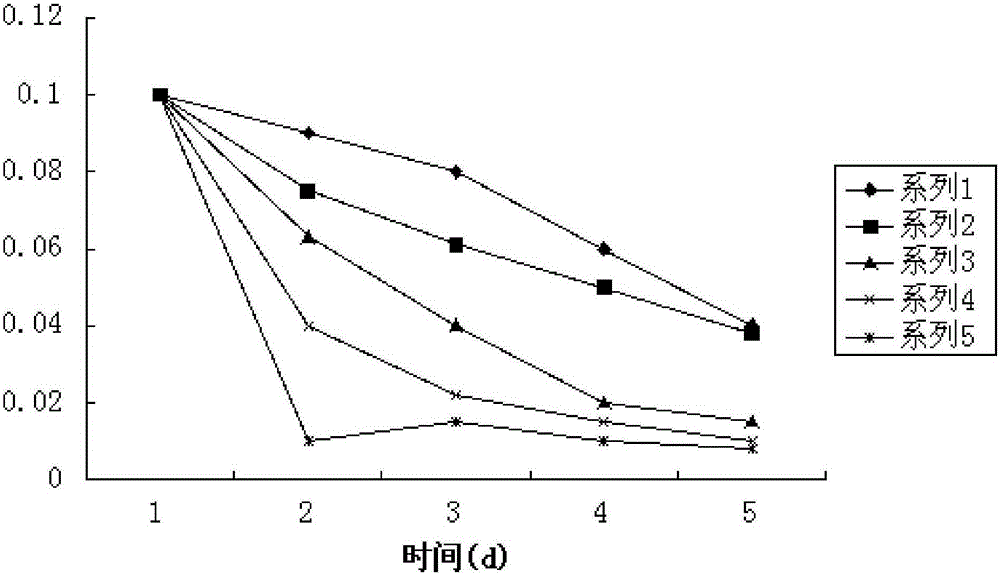

[0022] 2. Mix beer wastewater and BG11 liquid medium according to the volume ratio (v / v) of 1:1, 1:3, and 1:1. The three groups of medium are marked as c, d, and e in turn, and then respectively in c Add different concentrations of glucose in the culture medium of groups , d and e, and finally make the final content of glucose in the culture medium of the three groups be 5g / L, 7.5g / L, and 10g / L respectively; in addition, design two control groups, group a and group f, group a uses 100% waste water (that is, beer waste water without adding any other substances) as the medium, and group f uses beer waste water instead of distilled water to prepare BG11 medium, and then adds gluco...

Embodiment 2

[0040] 1) Pretreatment of beer wastewater: Sampling was taken at the entrance of the sewage treatment tank of a brewery in Lanzhou, which belongs to mixed wastewater. After the beer wastewater is retrieved, it is heated and boiled for 5 minutes, filtered with multi-layer gauze, cooled and stored in a sealed environment at 3°C;

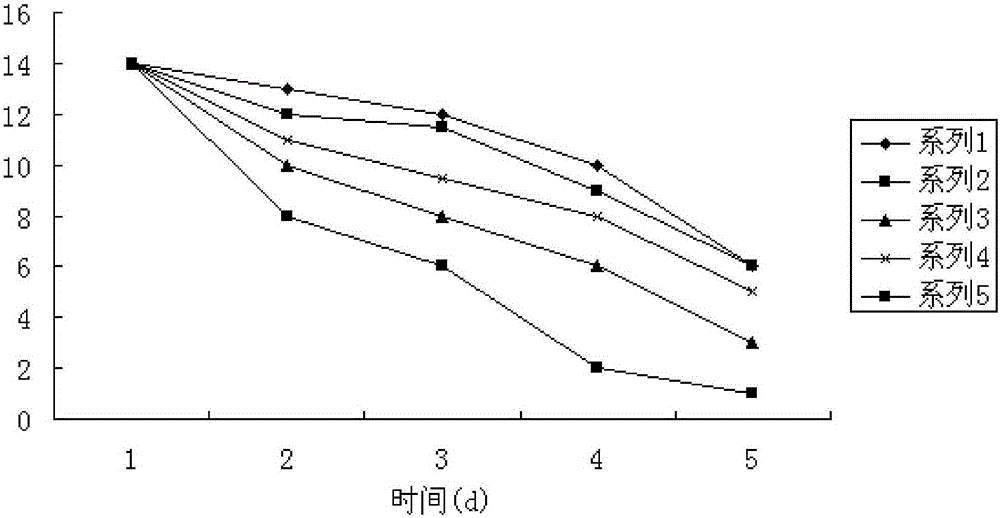

[0041] 2) Mix beer wastewater and BG11 liquid medium according to the volume ratio (v / v) of 1:1, 1:3, and 1:1, and the three groups of medium are marked as c, d, and e in turn, and then respectively in Different concentrations of glucose were added to the medium of groups c, d, and e, so that the final contents of glucose in the medium of the three groups were 5g / L, 7.5g / L, and 10g / L respectively; in addition, two control groups were designed, a Group and group f, group a uses 100% waste water (that is, beer waste water without adding any other substances) as the medium, and group f uses beer waste water instead of distilled water to prepare BG11 mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com