Built-in integrated water joint direction changing mechanism for single power, synchronous two-way mixing pile driver

A technology of changing direction mechanism and two-way stirring, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of high manufacturing cost, large size, inconvenient installation, etc., and achieve the expansion of connotation and extension, low manufacturing cost, The effect of expanding the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

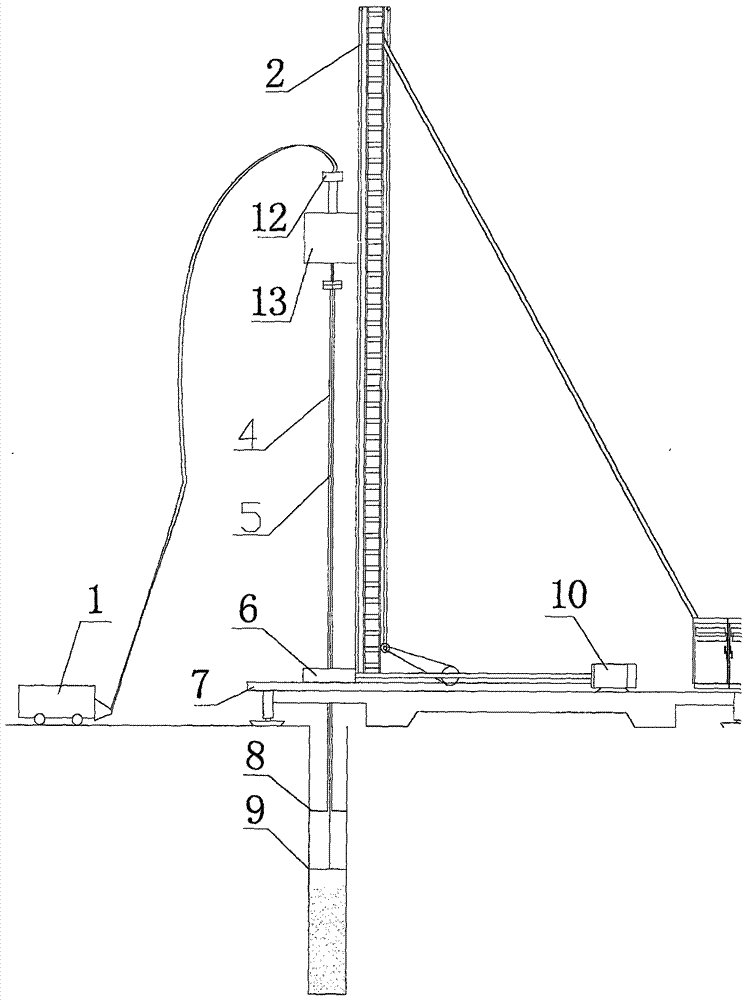

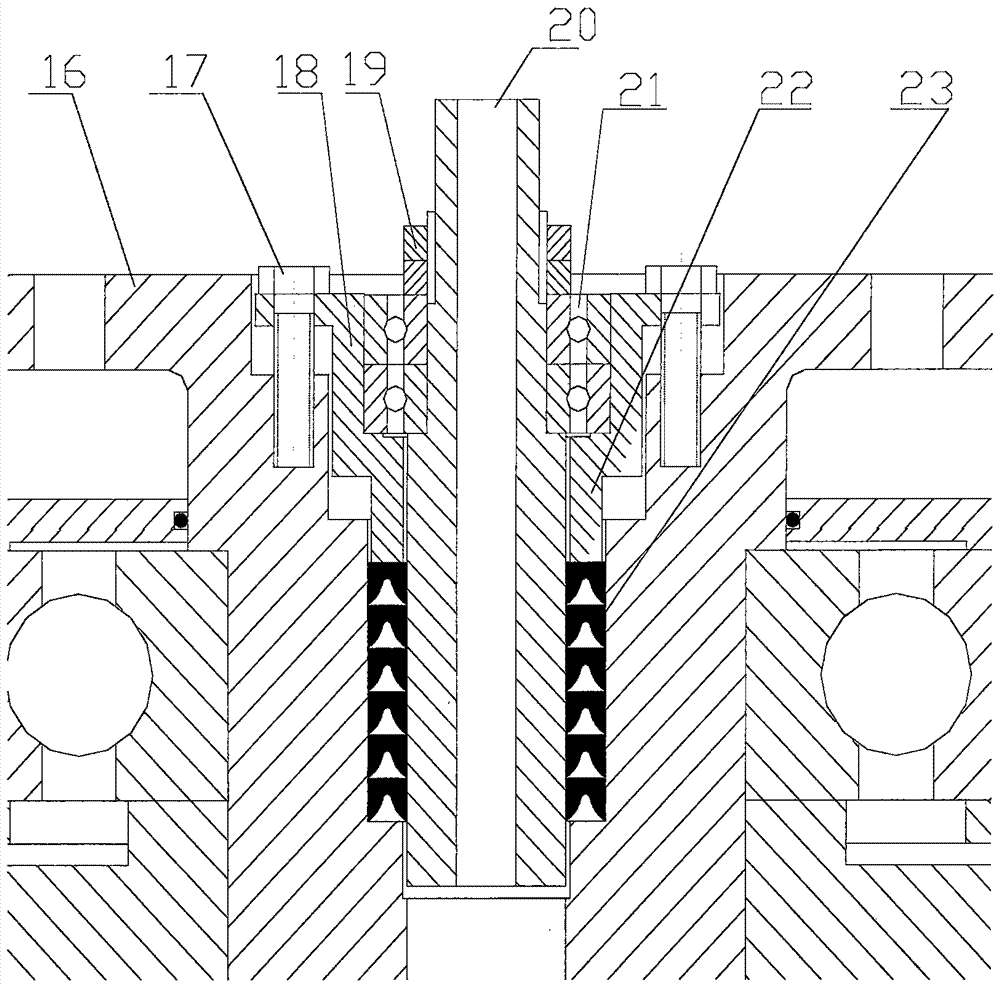

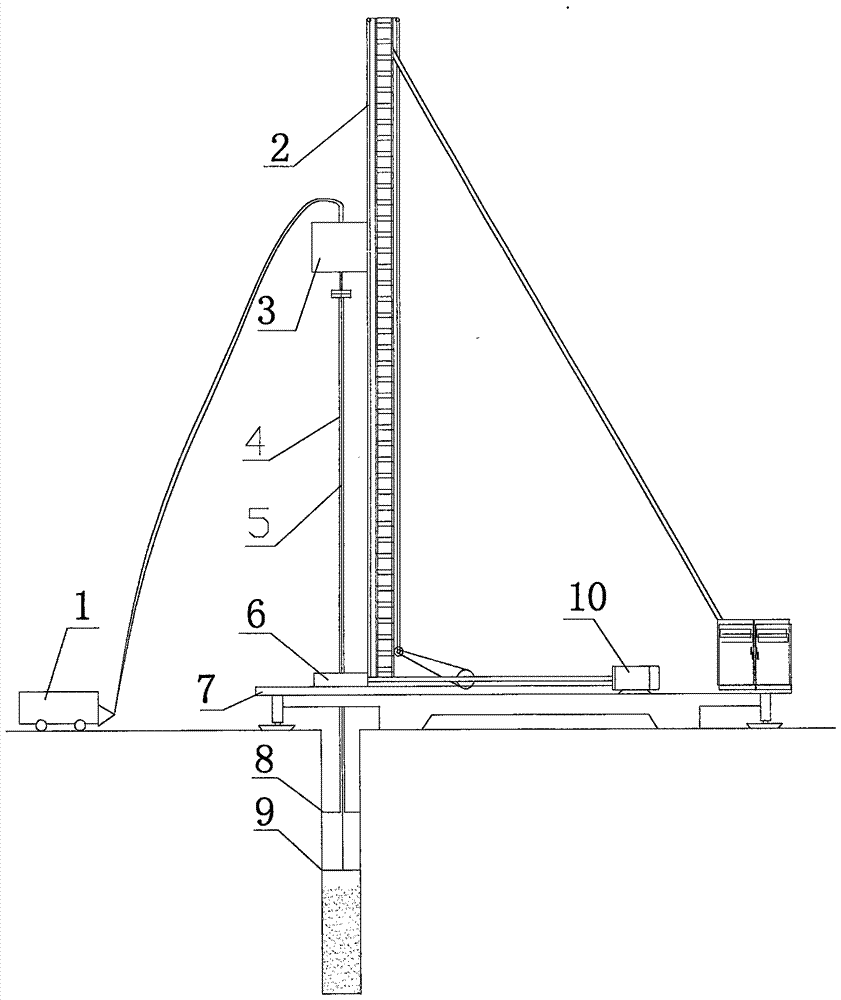

[0017] Such as figure 2 As shown, the built-in integrated water joint direction-changing mechanism for single-power, synchronous two-way mixing pile driver of the present invention includes a direction-changing mechanism and a water joint. in the transmission shaft 16.

[0018] Specifically, the top inner chamber of the transmission shaft 16 of the change-of-direction mechanism is provided with an expansion chamber, and the bottom end of the delivery shaft 20 of the water joint is inserted below the bottom of the transmission shaft 16 expansion cavity, and the delivery shaft 20 in the expansion cavity A pair of bearings 21 are set on the outer wall of the upper part. The bearing housing 18 located outside the bearings 21 is fixed in the expansion cavity. The delivery shaft 20 is fixed on the inner ring of the bearing 21 through a nut 19. It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com