Enclosing type deepwater platform construction method based on condition of sand backfilling balance method

A technology of sand return balance and construction method, applied in basic structure engineering, construction and other directions, can solve the problem of no reliable and effective construction method, and achieve the effect of high construction feasibility, guaranteeing construction safety, and reducing the cofferdam area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

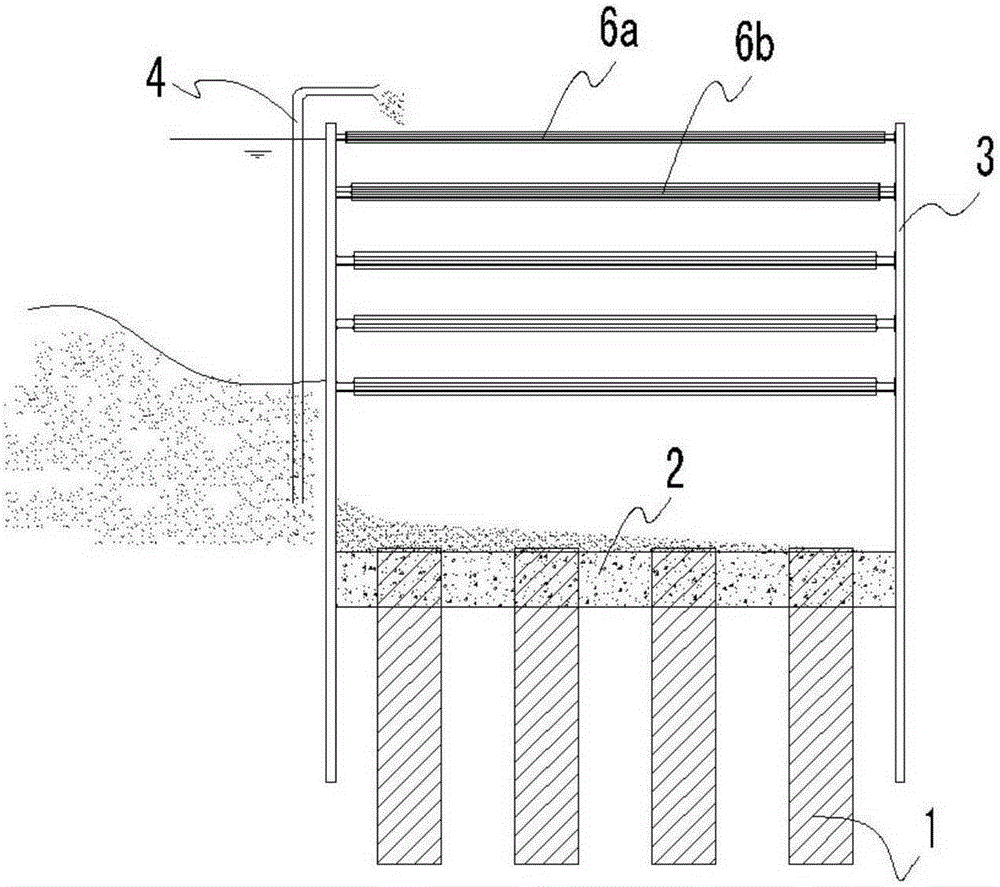

[0027] This example is in figure 1 The bridge cap foundation is built in the environment shown, such as figure 1 As shown, the riverbed where the steel sheet pile 3 is located below the water level is a sandy riverbed or other steep soil riverbed, the steel sheet pile 3 is embedded and driven to the depth of the riverbed, and the sandy surface of the riverbed surface has a relatively large slope, so it is not suitable for slotting Or other methods to fix the steel sheet pile.

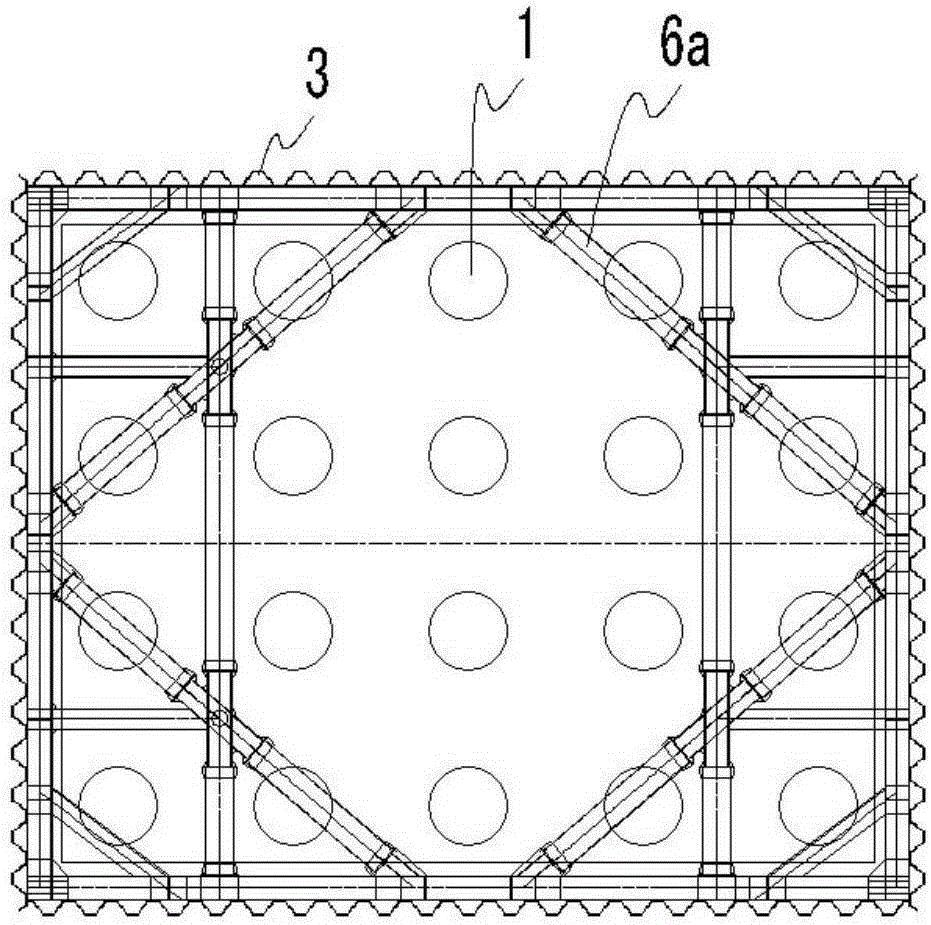

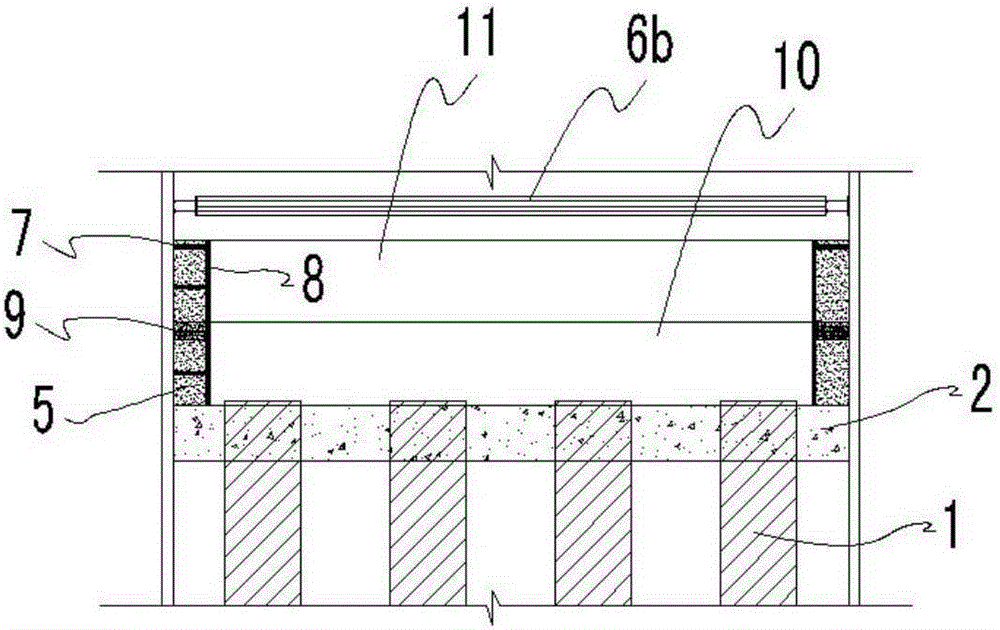

[0028] see figure 1 , figure 2 , image 3 and Figure 4 , in this embodiment, the construction method of the enclosure type deep-water cap platform based on the sand return balance method is carried out according to the following steps:

[0029] Step 1: Complete the hammering and inserting construction of the steel sheet pile 3 and the welding and installation construction of the inner support 6a in the top layer of the steel sheet pile 3 on the riverbed surface at the position of the cap to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com