Device and method for non-contact type measurement of large-deflection rotating shaft run-out

A non-contact, large-deflection technology, used in measuring devices, electrical devices, measuring/indicating equipment, etc., can solve problems such as measurement errors, easily damaged measuring instruments, and unsuitable measurement, to reduce measurement errors, high The effect of speed measurement and optimized shaft structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

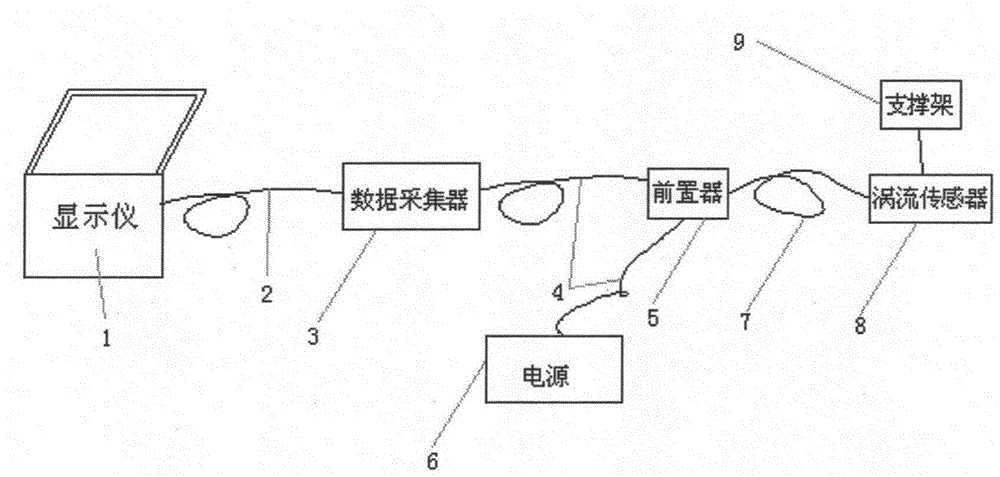

[0018] A non-contact device for measuring the runout of a large deflection shaft, such as figure 1 As shown, it includes display instrument 1 (or computer), display instrument 1 is connected with data collector 3 through USB data cable, data collector 3 is connected with front-end device 5 through two-core wire 4, front-end device 5 is connected with extension cable 7 It is connected with the eddy current sensor 8, and the eddy current sensor 8 is fixed in the support frame 9. During measurement, the probe top of the eddy current sensor 8 is generally 0.5 mm to 1.5 mm away from the journal or end surface to be measured. The support frame 9 includes an iron-absorbing seat, and the iron-absorbing seat of the support frame 9 is installed on the tool rest of the lathe, and the front device 5 is connected with the power supply 6 of -24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com