Thermal type gas mass flow-meter based on adjustable constant current source

A gas mass flow, constant current source technology, applied in indirect mass flow meters, mass flow measurement devices, etc., can solve problems affecting bridge balance, heating power increase circuit, and insensitivity to flow changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

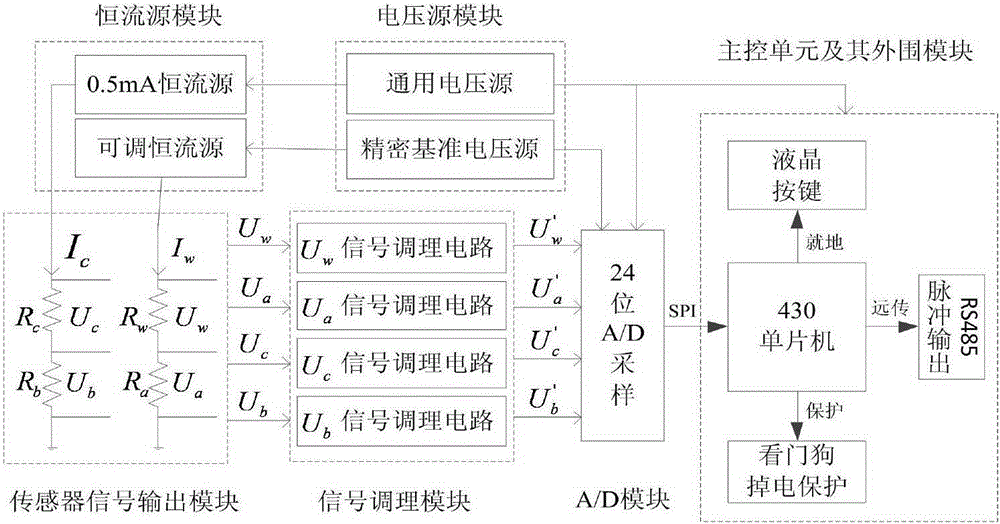

[0027] The mass flowmeter of the present invention, its complete machine circuit principle is as follows figure 1 shown.

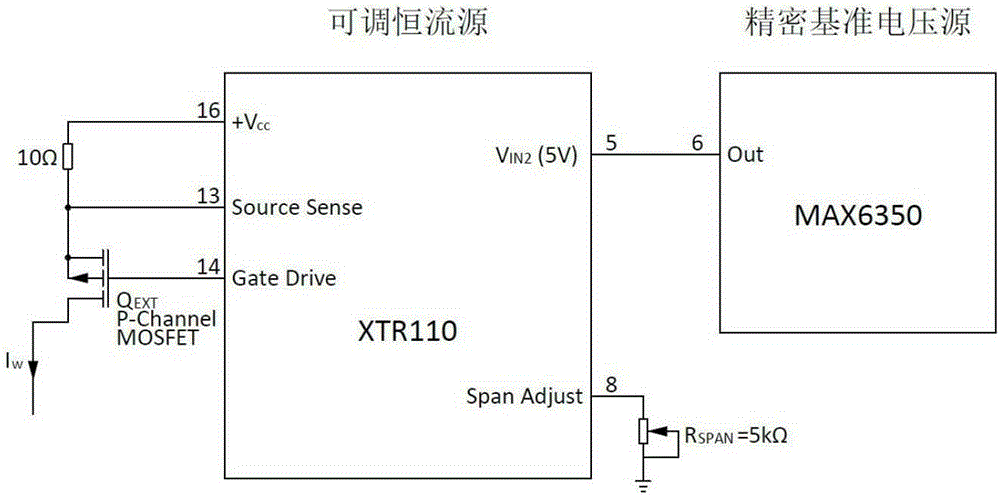

[0028] The whole machine is divided into sensor signal output module, constant current source module, voltage source module, main control unit and its peripheral modules, A / D module, and signal conditioning module. R C is the resistance value of the temperature measuring probe, from which we can know the temperature of the gas medium Tc; R W is the resistance value of the speed measuring probe, from which we can know the temperature Tw of the speed measuring probe; R a , R b It is the reference resistor, the resistance value is 100Ω, the accuracy is 0.01%, and the temperature drift is 5ppm.

[0029] R c = U c * ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com