System and method for measuring volume of glass measuring ware

A measuring system and glass measuring device technology, which is applied in the direction of volume measuring instruments/methods, container/cavity capacity measuring, measuring devices, etc., can solve the problems of large reading error and difficulty in realizing automation, so as to improve accuracy and measure The principle is novel and the effect of eliminating visual errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in more detail below in conjunction with the accompanying drawings.

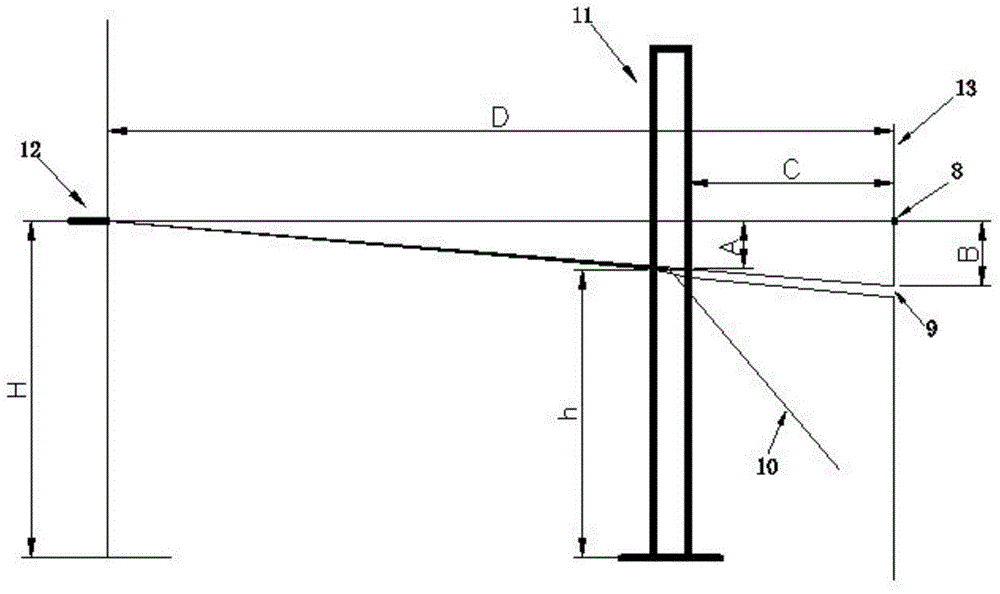

[0028] figure 1 The cross laser measurement system 1 includes a glass gauge 11 , a cross laser 12 and a screen 13 located on both sides of the glass gauge, and a camera 14 . The camera 14 is aimed at the screen for collecting images on the screen 13, and the camera 14 is connected with the data processing system, and transmits the collected images to the data processing system for processing. Combine below figure 1 Explain the principle of the cross laser measurement system 1 to measure the liquid level: the cross laser 12 emits a red cross laser line with a wavelength of 650nm. After the laser line passes through the glass measuring device 11, it is projected on the screen, and the center of the cross is the reference point. When the laser line shoots to the liquid surface in the glass measuring vessel, due to the existence of refraction phenomenon, this part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com