Nylon glass fiber composite material bottom shell of notebook computer and injection molding technology of nylon glass fiber composite material bottom shell

A notebook computer and composite material technology, applied in the direction of electrical digital data processing, instruments, digital data processing components, etc., can solve the problems of poor heat dissipation, heavy weight, cracks, etc., and achieve light weight, simple manufacturing process, and thermal conductivity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

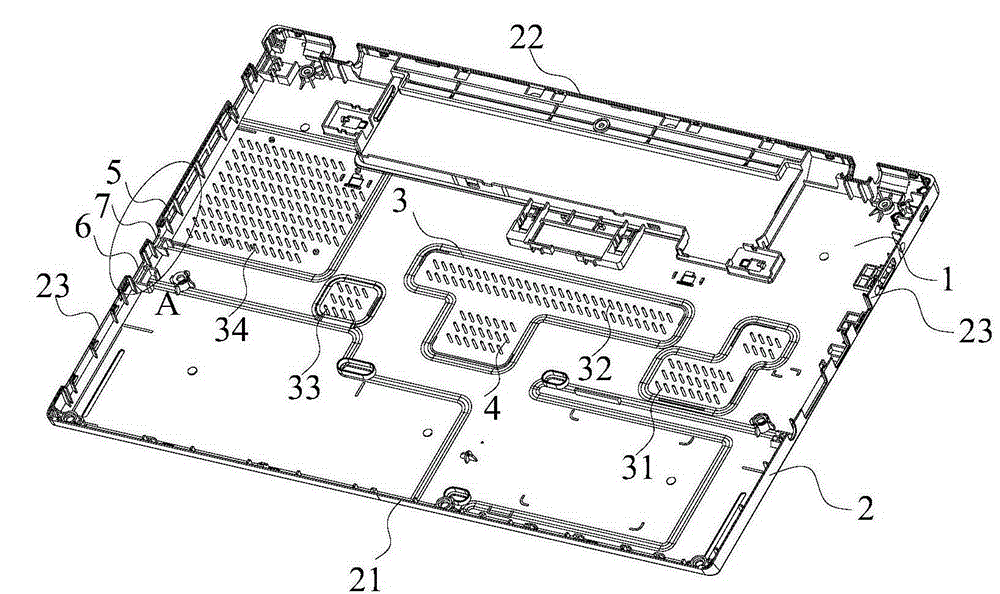

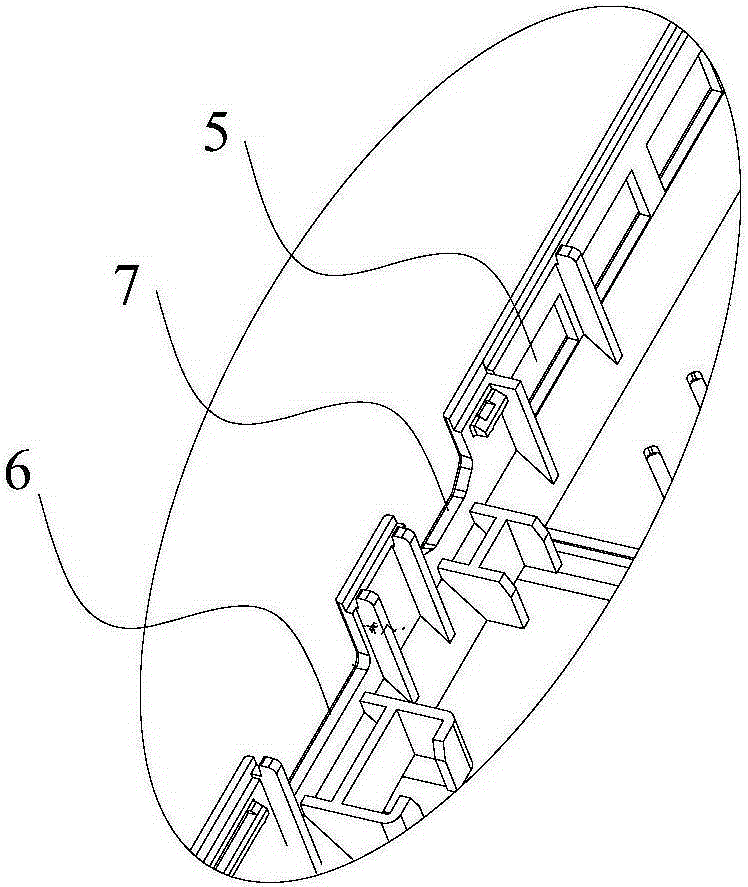

[0031] This embodiment provides a notebook computer bottom case made of nylon fiberglass composite material, such as figure 1 and figure 2 As shown, the bottom case includes a bottom plate 1 and a frame 2 connected to the periphery of the bottom plate 1, and the frame 2 is located on the same surface of the bottom plate 1, and the frame 2 includes a front frame 21, a rear frame 22 and a side frame 23. The rear frame 22 is hinged with the computer display screen. The front frame 21 is connected with the side frame 23 and the rear frame 22 is connected with the side frame 23 with rounded corners. The side frame 23 is provided with no less than one USB port 6 and network port 7, the USB port 6 and the network port 7 are U-shaped holes with upper openings, and the U-shaped holes are connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com