Method for reducing heating of electric joint and copper bars adopting method

A technology for electrical connectors and heating devices, applied in electrical components, circuits, connections, etc., can solve problems such as difficult realization, limited effect, and reduction of heat generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

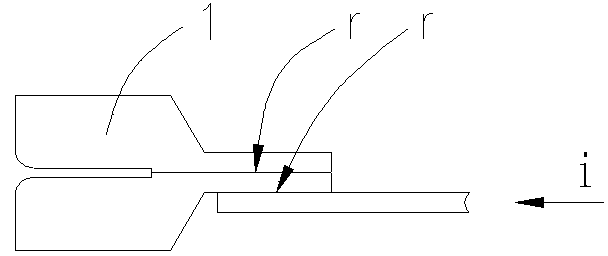

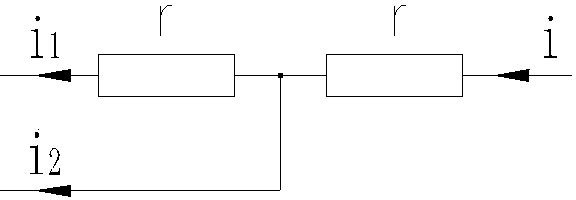

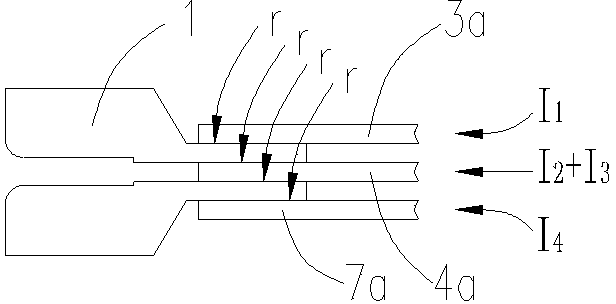

[0031] In a pure resistance circuit, it is assumed that the contact surface resistance and contact pressure between conductors are constant, ignoring the DC resistance of the conductors, according to the electrical power formula P=I 2 r, the heating power P of the electrical joint contact resistance r is proportional to the square of the current I(i), and is proportional to the contact resistance r. figure 1 It is a schematic diagram of the connection between the two wire lugs 1 and the copper bar of the existing circuit, from figure 2 The equivalent circuit diagram of resistors in series shows that: i=i 1 + i 2 ,i 1 = i, so, ∑P 1~2 = i 2 r+( i) 2 r= i 2 r; image 3 It is a schematic diagram of the connection between two wire lugs 1 and three copper bars, from Figure 4 The parallel equivalent circuit diagram of resistors shows that: I 1 =I 2 =I 3 =I 4 = I, so, ΣP 1~4 =4x(1 / 4I) 2 r= I 2 r; ΣP 1~2 / ∑P 1~4 =5, the contact heating power is the existing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com