Housing for an electrical machine

A shell and shell wall technology, applied in the direction of casing/housing/support, electrical components, electromechanical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

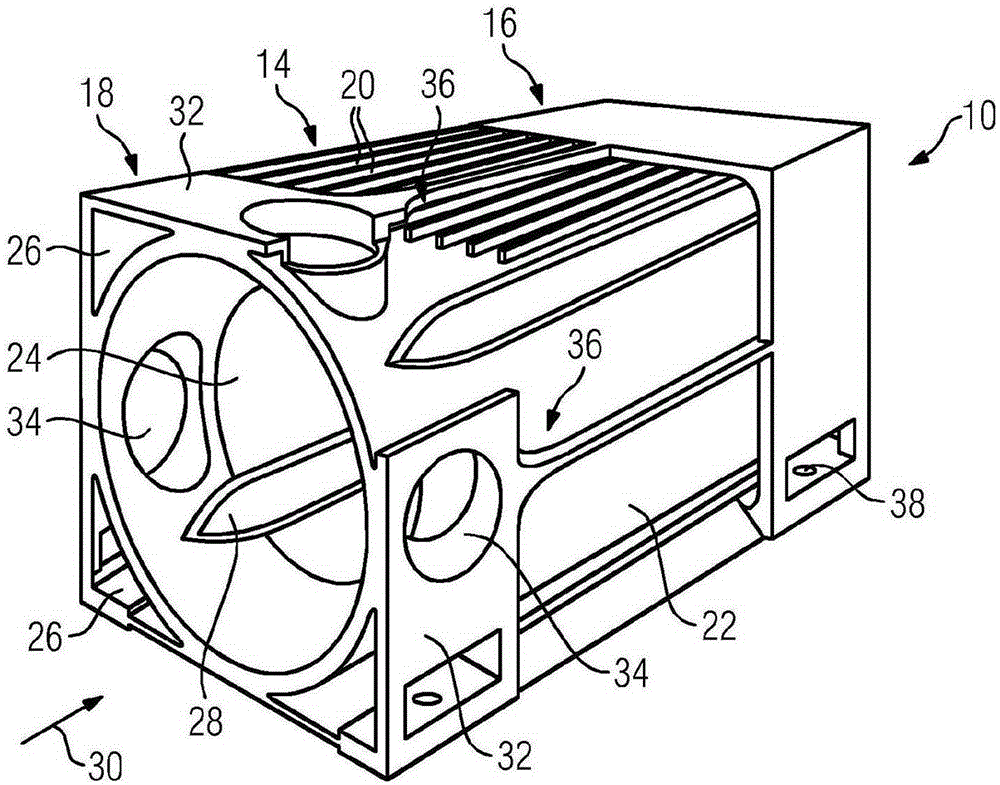

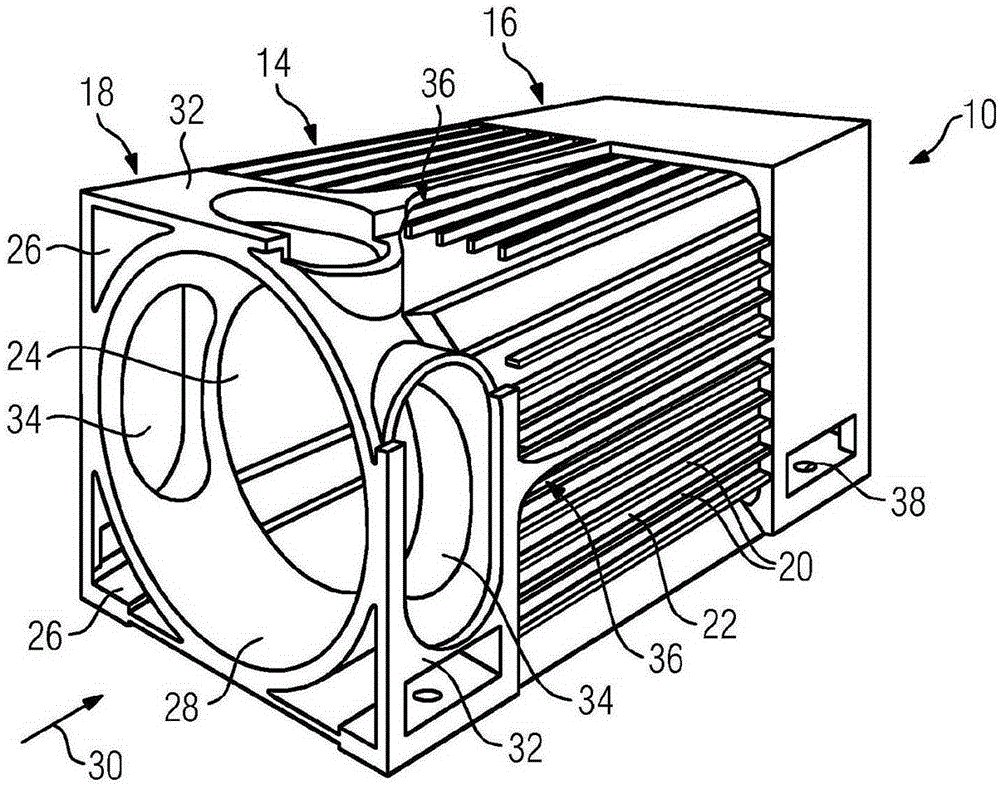

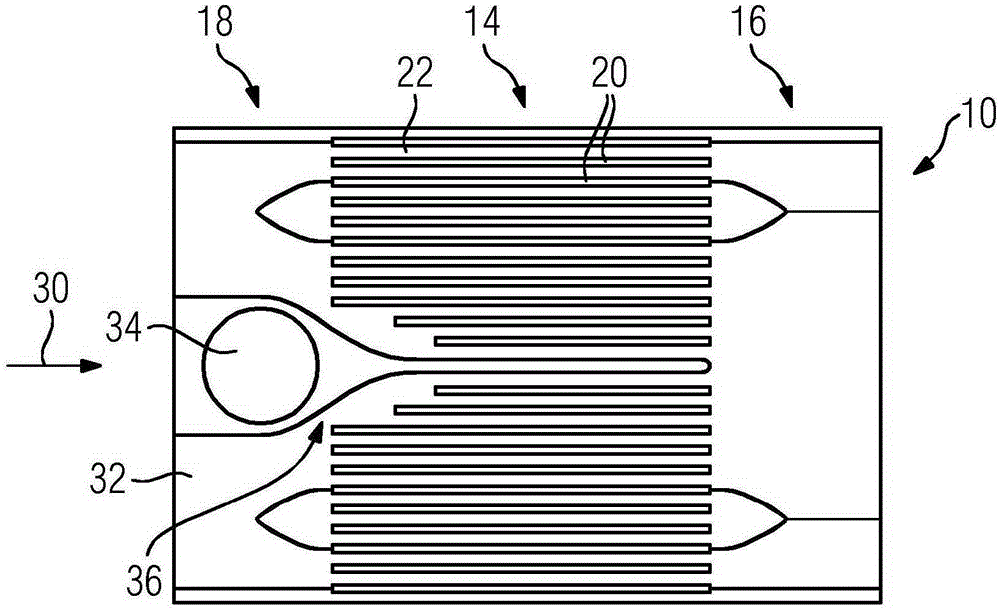

[0042] figure 1 The housing 10 for the electric motor 12 is shown in perspective. Housing 10 of electric machine 12 is divided into three regions 14 , 16 and 18 . In a cooling region 14 , which corresponds to a central region of the housing 10 , the housing comprises a plurality of cooling fins 20 , which are presently shown only in the upper region of the housing 10 . The cooling fins 20 are arranged on the outer surface of the housing wall 22 . The housing wall 22 essentially has a hollow cylindrical shape. The housing 10 can be made of gray cast iron or steel, for example. Because the housing 10 in the interior 24 has a substantially circular cross section, the housing 10 can be produced by means of turning.

[0043] Furthermore, the housing 10 has a coolant supply region 16 , which leads to the cooling region 14 . The coolant supply area 16 has a rectangular or square cross section. In the coolant supply region 16 there is at least one channel which serves to supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com