Printed circuit board with blind holes and processing method of printed circuit board

A technology for printed circuit boards and processing methods, applied in printed circuits, printed circuits, printed circuit manufacturing, etc., can solve the problems of slag residue, long laser time, laser penetration, etc., to achieve diversity and no slag residue. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for processing a printed circuit board with blind holes comprises the following steps:

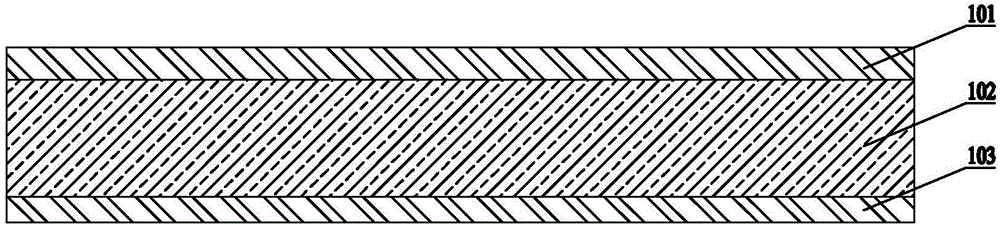

[0028] a. Take the semi-finished printed circuit board. The semi-finished printed circuit board has an upper copper foil layer 101, a base material layer 102 and a lower copper foil layer 103. The upper copper foil layer 101 is arranged on the upper surface of the base material layer 102, and the lower copper foil layer 103 is arranged on the lower surface of the substrate layer 102, the thickness of the upper copper foil layer 101 is 12 μm, the thickness of the substrate layer 102 is 0.05 mm, the material of the substrate layer 102 is FR4, and the thickness of the lower copper foil layer 103 is 12 μm;

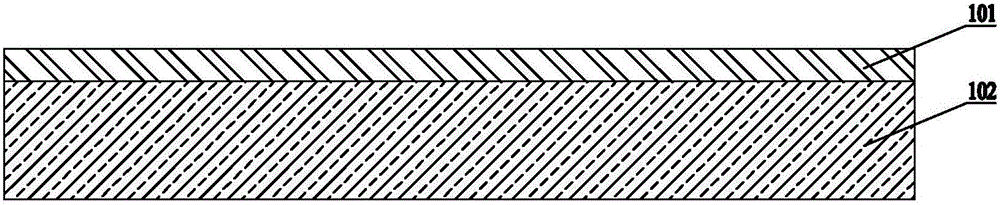

[0029] b. Etching off the copper foil layer 103 by using an etching solution and adopting a conventional etching process, the etching solution is a mixed solution mainly containing copper chloride, hydrochloric acid and hypochlorous acid;

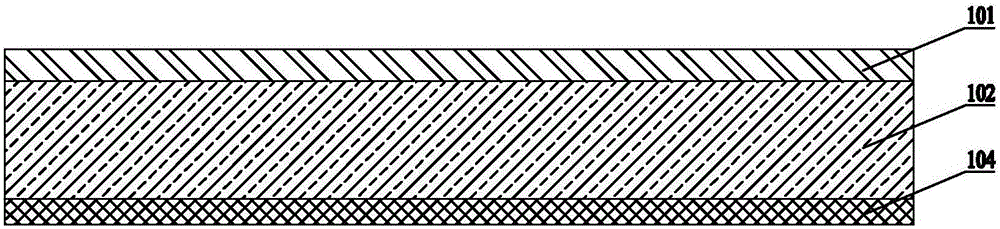

[0030] c. Heating the epoxy resin...

Embodiment 2

[0035] A method for processing a printed circuit board with blind holes comprises the following steps:

[0036] a. Take the semi-finished printed circuit board. The semi-finished printed circuit board has an upper copper foil layer 101, a base material layer 102 and a lower copper foil layer 103. The upper copper foil layer 101 is arranged on the upper surface of the base material layer 102, and the lower copper foil layer 103 is arranged on the lower surface of the substrate layer 102, the thickness of the upper copper foil layer 101 is 105 μm, the thickness of the substrate layer 102 is 3 mm, the material of the substrate layer 102 is FR4, and the thickness of the lower copper foil layer 103 is 105 μm;

[0037] b. Etching off the copper foil layer 103 by using an etching solution and adopting a conventional etching process, the etching solution is a mixed solution mainly containing copper chloride, hydrochloric acid and hypochlorous acid;

[0038] c. Heating the epoxy resin ...

Embodiment 3

[0043] A method for processing a printed circuit board with blind holes comprises the following steps:

[0044] a. Take the semi-finished printed circuit board. The semi-finished printed circuit board has an upper copper foil layer 101, a base material layer 102 and a lower copper foil layer 103. The upper copper foil layer 101 is arranged on the upper surface of the base material layer 102, and the lower copper foil layer 103 is arranged on the lower surface of the substrate layer 102, the thickness of the upper copper foil layer 101 is 50 μm, the thickness of the substrate layer 102 is 1.5 mm, the material of the substrate layer 102 is FR4, and the thickness of the lower copper foil layer 103 is 50 μm;

[0045] b. Etching off the copper foil layer 103 by using an etching solution and adopting a conventional etching process, the etching solution is a mixed solution mainly containing copper chloride, hydrochloric acid and hypochlorous acid;

[0046] c. Heating the epoxy resin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com