Electroconductive composite and its producing method

A manufacturing method and composition technology, which is applied in the field of conductive composition and its manufacture, can solve the problems of high cost and achieve the effect of reducing resistivity and suppressing excessive heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

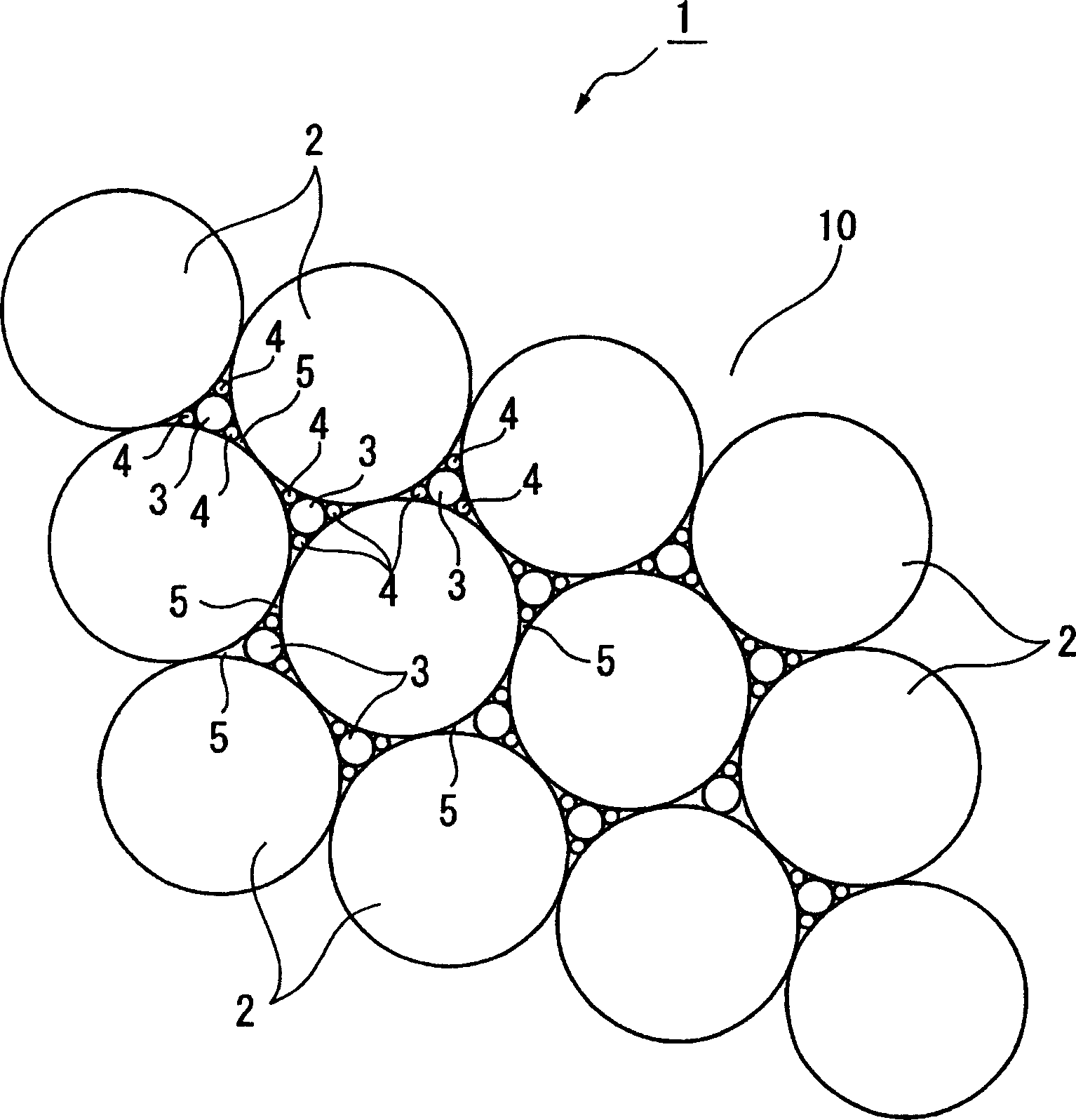

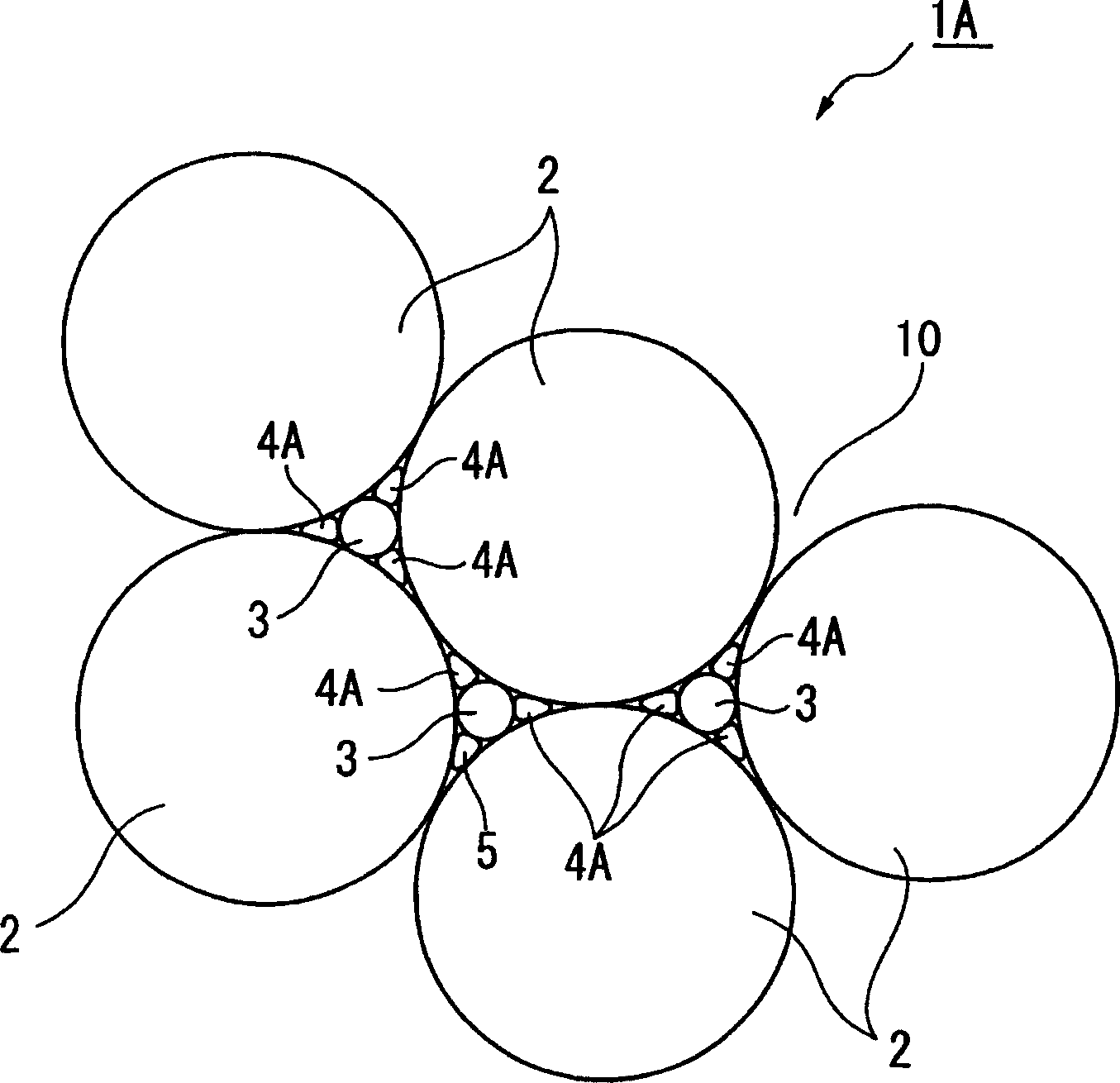

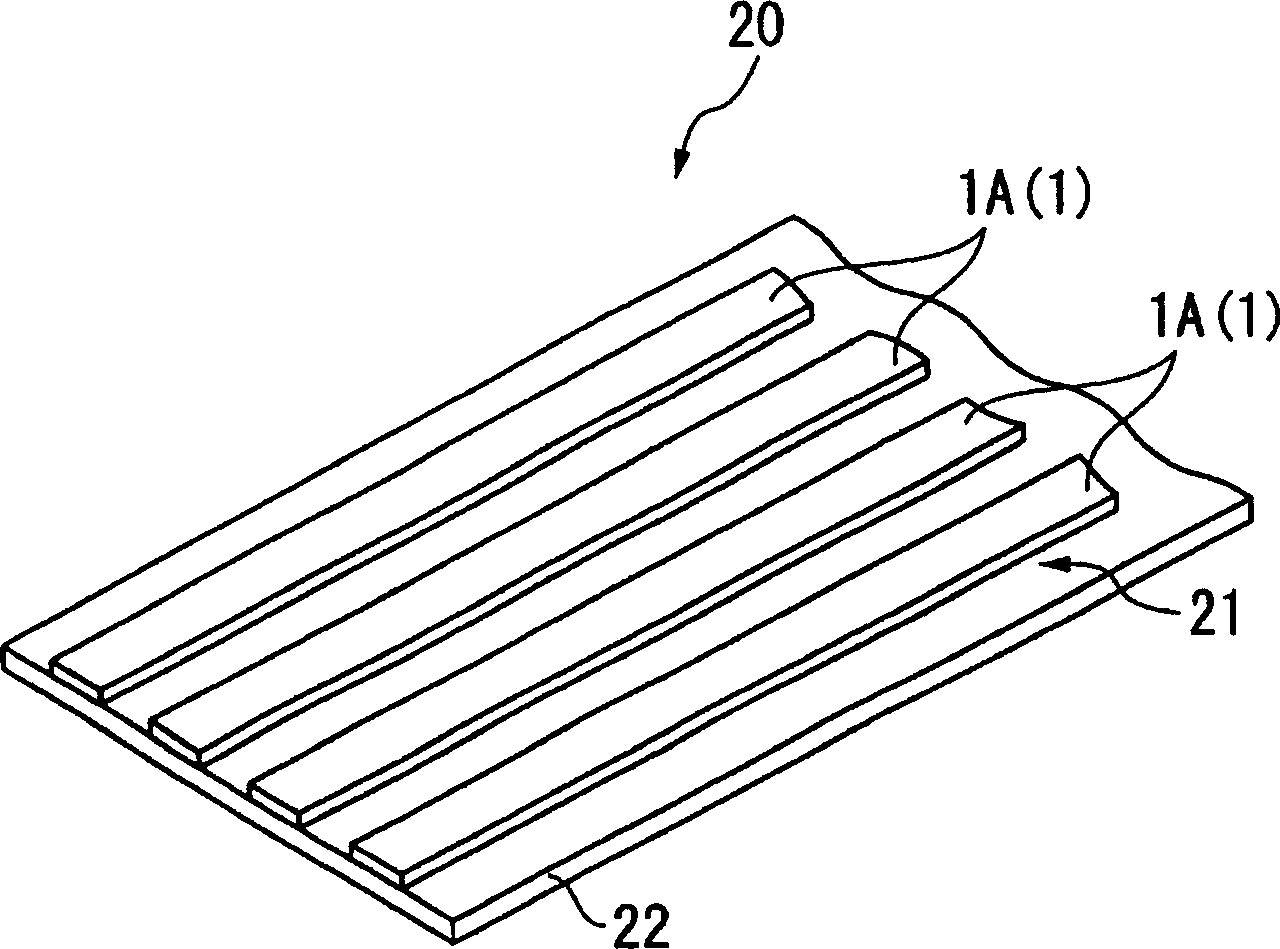

[0023] figure 1 is a filling structure diagram showing the state before the conductive composition of the present invention hardens, figure 2 It is a filling structure diagram showing the state of the conductive composition of the present invention after curing. image 3 It is a perspective view showing a circuit board. However, although figure 1 and figure 2 Each represents a regular arrangement state as explained, but is actually not limited to this state.

[0024] Such as figure 1 As shown, the conductive composition 1 of the present invention contains a conductive material 2 and another conductive material 3 smaller than the aforementioned conductive material in a specific binder resin 10 . The above-mentioned conductive materials 2 and 3 are respectively in the form of particles, and the average particle diameter of the conductive material 2 is formed to be much larger than the average particle diameter of the conductive material 3 . For example, when figure 1 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com