Flunixin meglumine taste masking orally-disintegrating preparation and preparing method thereof

A flunixin meglumine and orally disintegrating technology, which is applied in anti-inflammatory agents, pill delivery, pharmaceutical formulations, etc., can solve the problems that there are no reports of flunixin meglumine orally disintegrating tablets, and achieve advanced technology , less contact, improved taste masking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

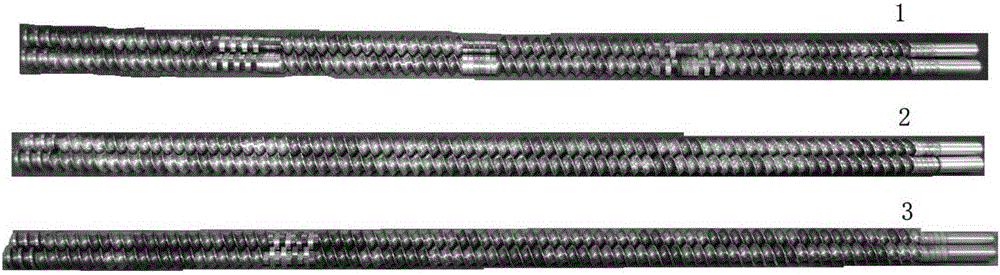

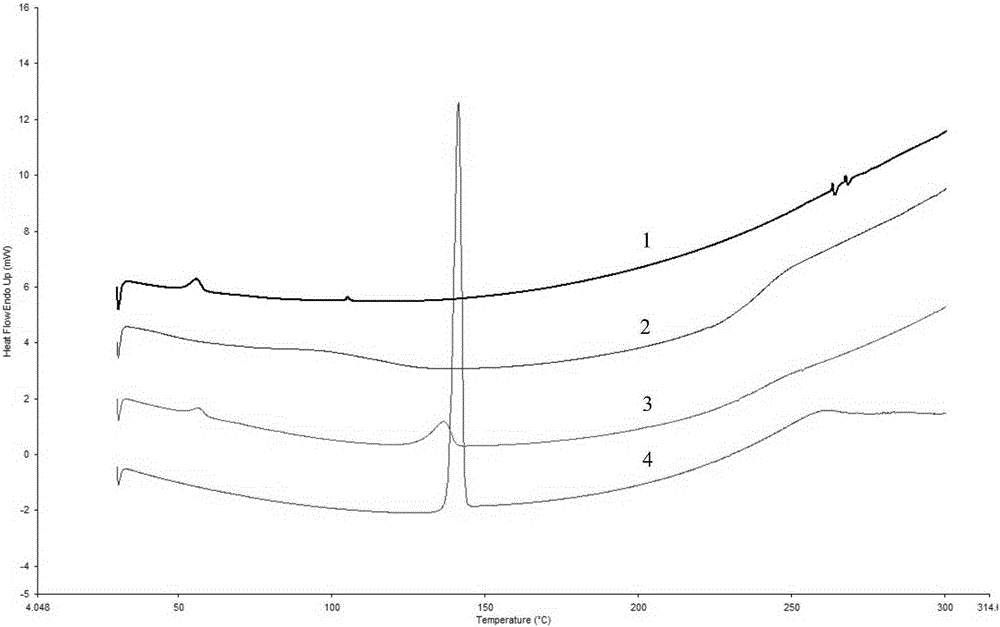

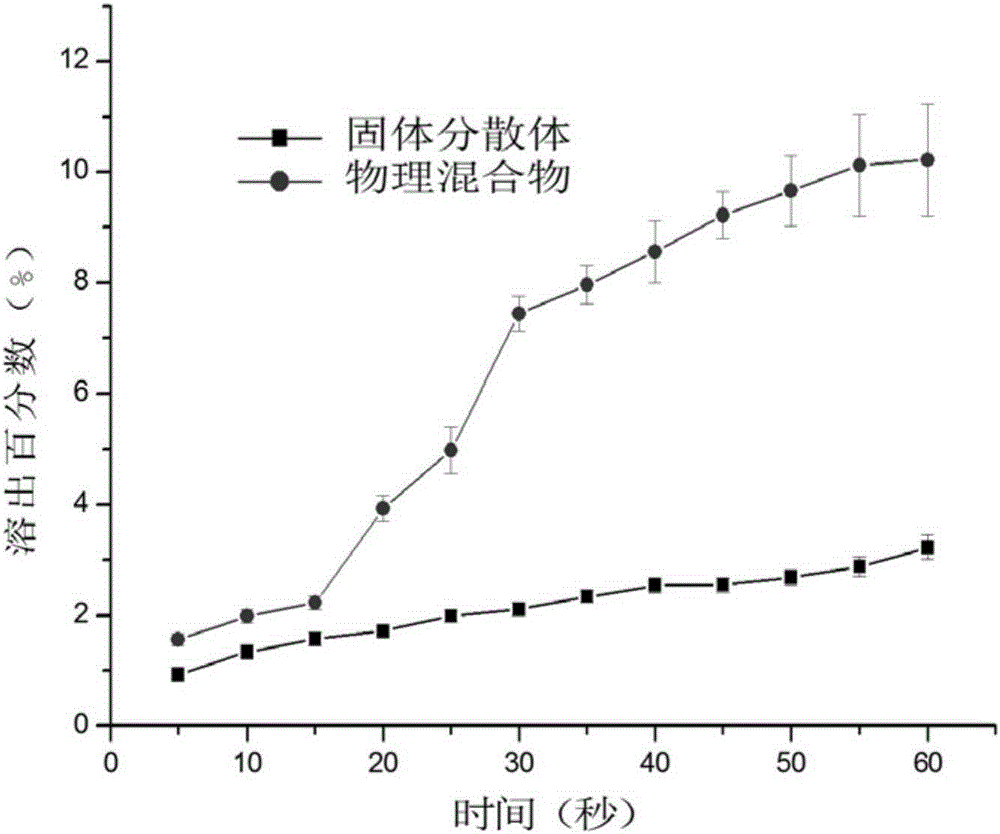

[0034] The first step is to take the raw materials flunixin meglumine and EudragitEPO respectively, pulverize them, pass through an 80-mesh sieve, and mix them uniformly in a ratio of 1:2 according to the equal-volume incremental dilution method to prepare a physical mixture; choose a screw with a diameter of 16-24mm Twin-screw extruder, set the twin-screw extruding element as the screw element of single mixing kneading figure 1 The screw structure shown in 3), the melt extrusion temperature of the extruder is 140 °C, after the temperature rises to the set value, the screw speed is set to 100rpm / min, after the speed is stable, add the physical mixture, and pass through the extruder Melting, shearing, and conveying to obtain a yellow transparent strip extrudate; after the extrudate is cooled, it is crushed and sieved, and the sieve of 30 to 50 meshes is retained to obtain a taste-masked solid dispersion of flunixin meglumine body.

[0035] In the second step, the ingredients i...

Embodiment 2

[0037] The first step is to take the raw materials of flunixin meglumine, EudragitEPO, KollicoatSmartseal30D, and ethyl cellulose respectively, grind them, pass through a 90-mesh sieve, and mix them uniformly in the ratio of 1:2:1:1 by the method of equal incremental dilution to prepare into a physical mixture; select a twin-screw extruder with a screw diameter of 16-24 mm, and set the twin-screw extrusion element as a single-mixing kneading screw element (such as figure 1 The screw structure shown in 3), the melt extrusion temperature of the extruder is 155 °C, after the temperature rises to the set value, the screw speed is set to 150rpm / min, and the physical mixture is added after the speed is stable, and the extruder Melting, shearing, and conveying to obtain a yellow transparent strip-shaped extrudate; after the extrudate is cooled, it is crushed and sieved, and the sieved material of 40 to 50 meshes is retained to obtain a taste-masked solid dispersion of flunixin meglumi...

Embodiment 3

[0040] The first step is to take the raw materials flunixin meglumine and acrylic resin IV respectively, crush them, pass through a 60-mesh sieve, and mix them uniformly in the ratio of 1:4 by equal incremental dilution method to prepare a physical mixture; choose a screw with a diameter of 16~ 24mm twin-screw extruder, set the twin-screw extrusion element as a screw element of a single mixing kneading block (such as figure 1 The screw structure shown in 3), the melt extrusion temperature of the extruder is 135°C, after the temperature rises to the set value, set the screw speed to 80rpm / min, add the physical mixture after the speed stabilizes, and pass through the extruder Melting, shearing, and conveying to obtain a yellow transparent strip-like extrudate; after the extrudate is cooled, it is crushed and sieved, and the sieve of 35 to 50 meshes is retained to obtain a taste-masked solid dispersion of flunixin meglumine body.

[0041] In the second step, mix the ingredients ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com