High-efficiency low-energy-consumption powder concentrator

A technology of low energy consumption and powder separator, applied in the direction of solid separation, separating solid from solid with air flow, chemical instruments and methods, etc., can solve the problem of easy erosion and wear, limited service life, and low efficiency of powder separator and other problems, to achieve the effect of increased service life, increased efficiency, and reduced coal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

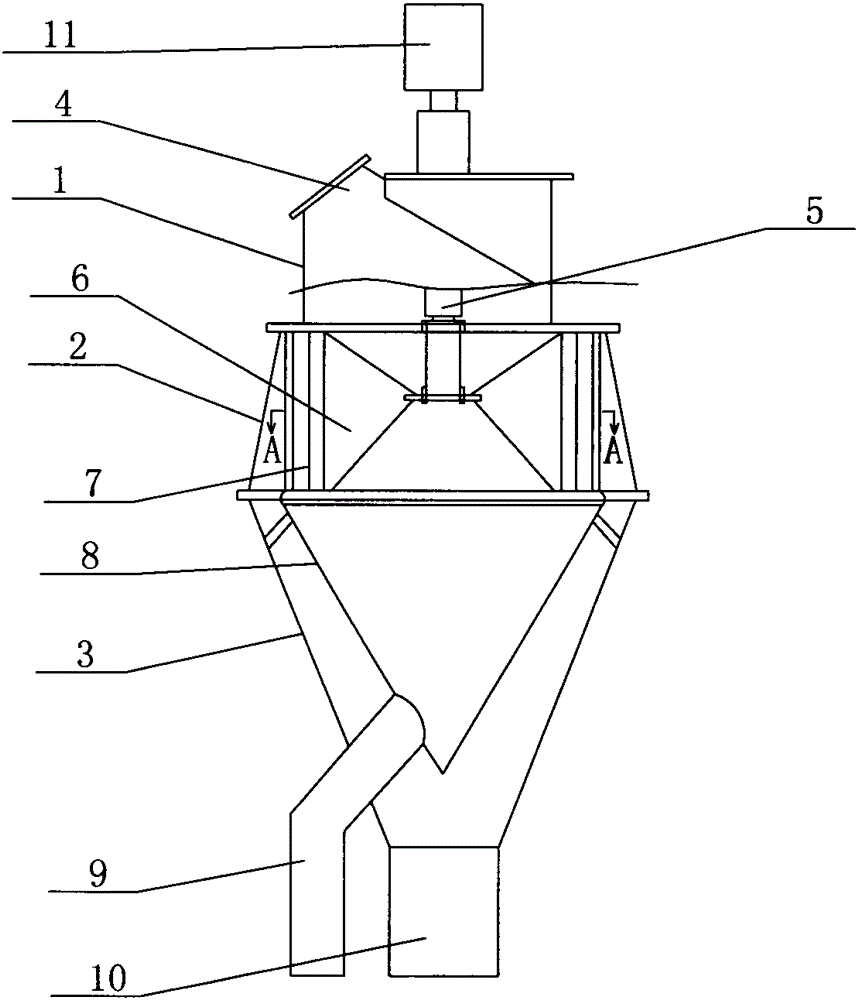

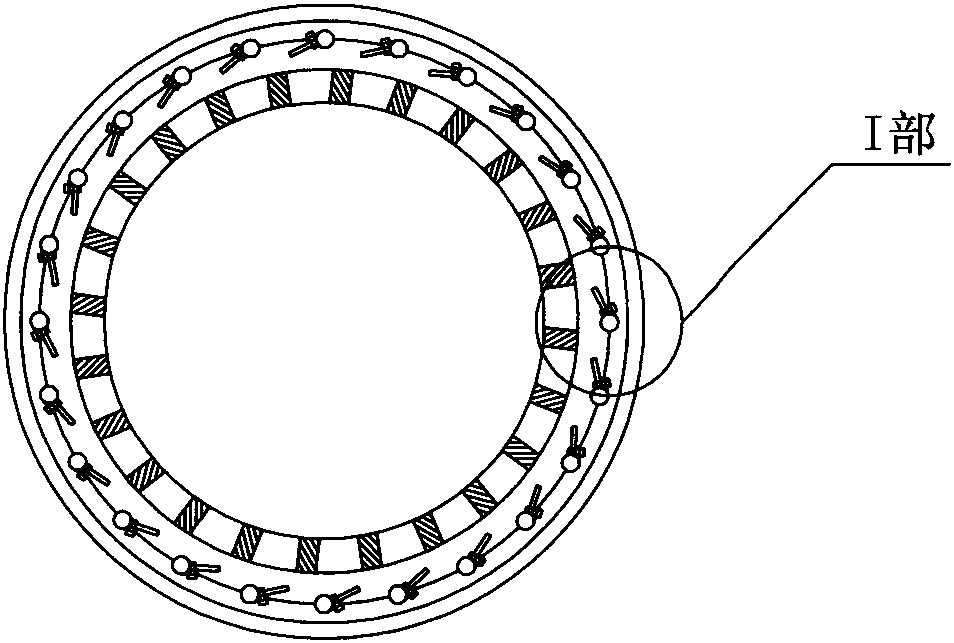

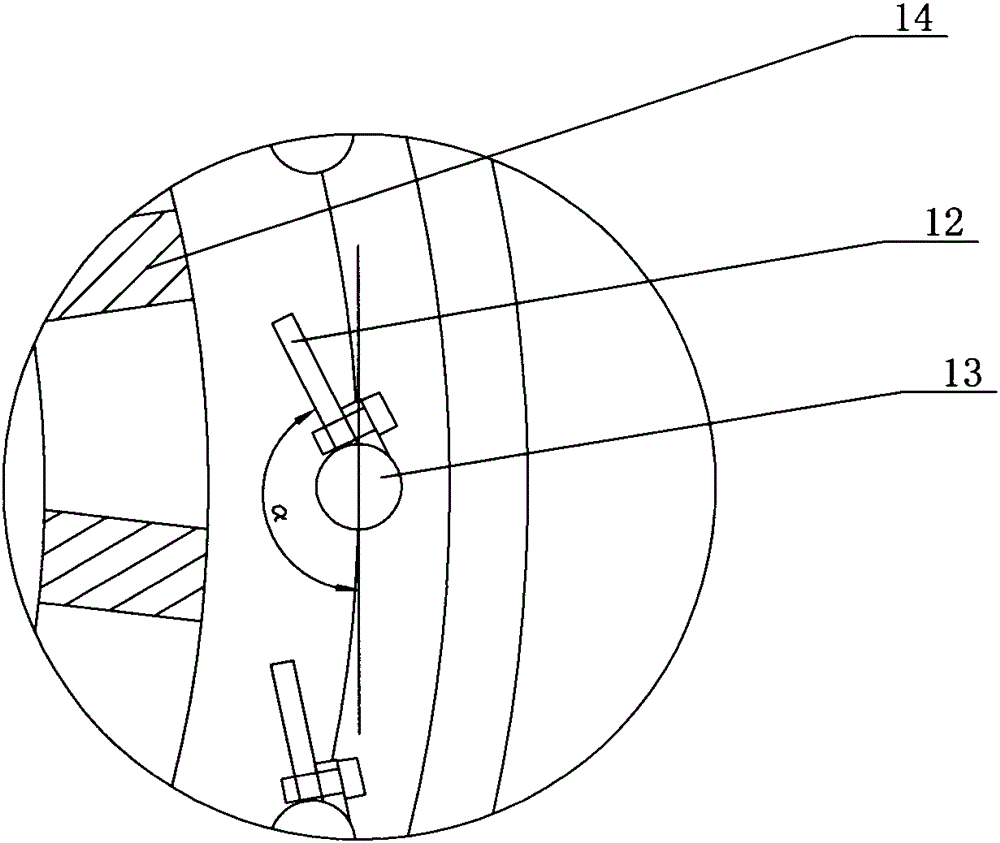

[0018] see Figure 1-Figure 3 As shown, the technical solution adopted in this specific embodiment is: it includes an upper casing 1, a middle casing 2, a discharging casing 3, a feeding port 4, a main shaft 5, a rotor 6, a stator 7, and a coarse material receiving hopper 8 , coarse material discharge pipe 9, finished product discharge pipe 10, motor 11, stator blade 12, stator shaft 13, rotor blade 14; the lower part of the upper casing 1 is provided with a middle casing 2, and the lower part of the middle casing 2 is provided with The discharge casing 3, the lower part of the discharge casing 3 is provided with a finished product discharge pipe 10, the upper casing 1 is provided with a feeding port 4, and the upper casing 1 is provided with a motor 11, and the motor 11 is connected with the main shaft 5 through the main shaft 5. The rotor 6 is connected, the outer p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com