Nut casting die

A technology of casting molds and molds, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems that affect the casting effect and casting quality of castings, the comprehensive economic benefits of nut casting are low, and the external dimensions are difficult to control, so as to achieve saving Manpower, increase production efficiency, and fast production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

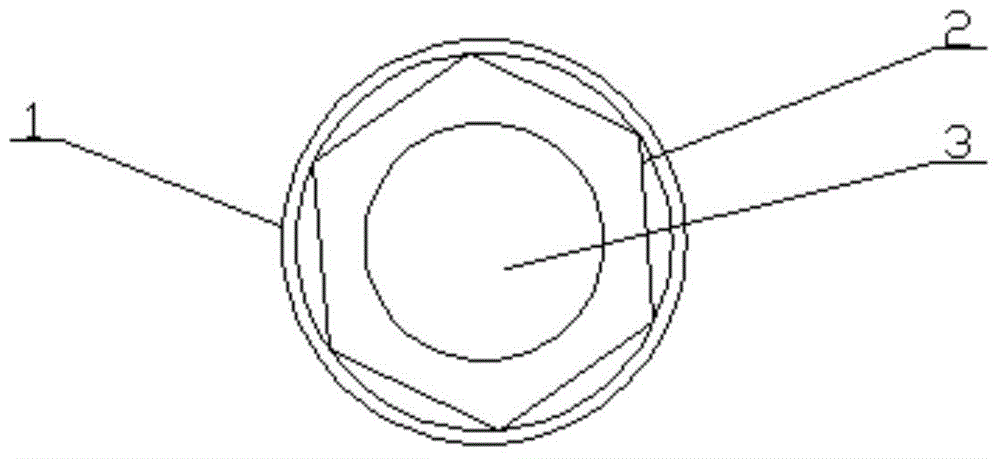

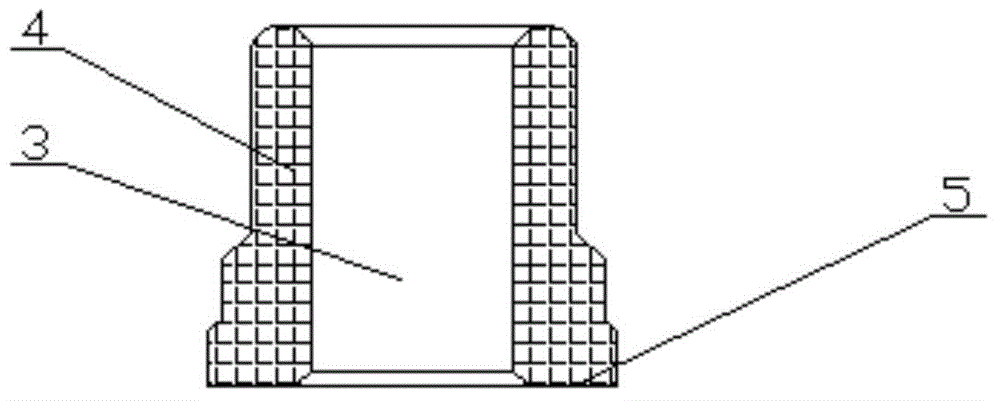

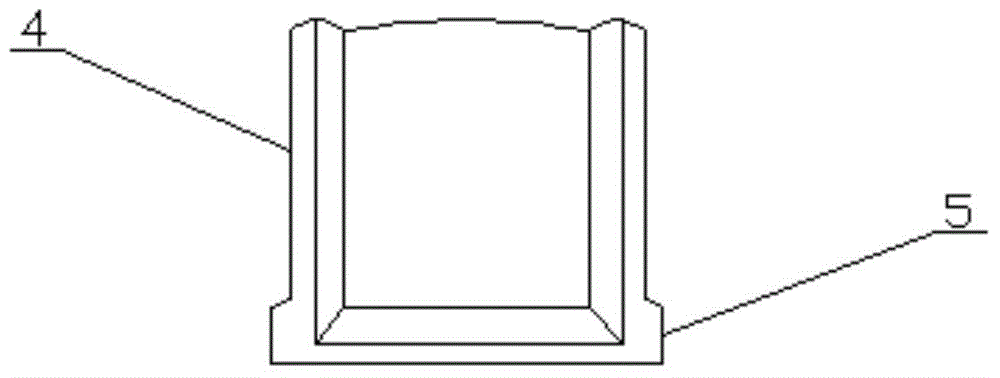

[0018] Example: see Figure 1-3 , a nut casting mold according to the present invention includes a mold body 1, and the mold body 1 includes an upper cavity 4 and a base 5, and the upper cavity 4 and the base 5 are integrally formed.

[0019] The top of the mold body 1 is provided with a groove 2, and the inside of the groove 2 is provided with a hexagonal through hole 3. The setting of the hexagonal through hole 3 can effectively ensure the appearance of the casting. The outer shape of the mold body 1 is made of resin It is made by sand molding process. Due to the high strength of resin sand, the casting will not expand after casting, avoiding manual grinding, saving manpower and casting cost. At the same time, the outer dimension of the casting is controlled within 1.5mm, ensuring the The size is stable, the output is large, the production speed is fast, and the efficiency is greatly improved. The groove 2 is circular.

[0020] It should be noted that the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com