A system and method for automatically assembling a water pump assembly

An automatic assembly and automatic technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems that the production line cannot be automatically traced, the assembly efficiency is reduced, and the labor cost is high, so as to prevent the outflow of substandard products and avoid leakage. The effect of installation and wrong installation, reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

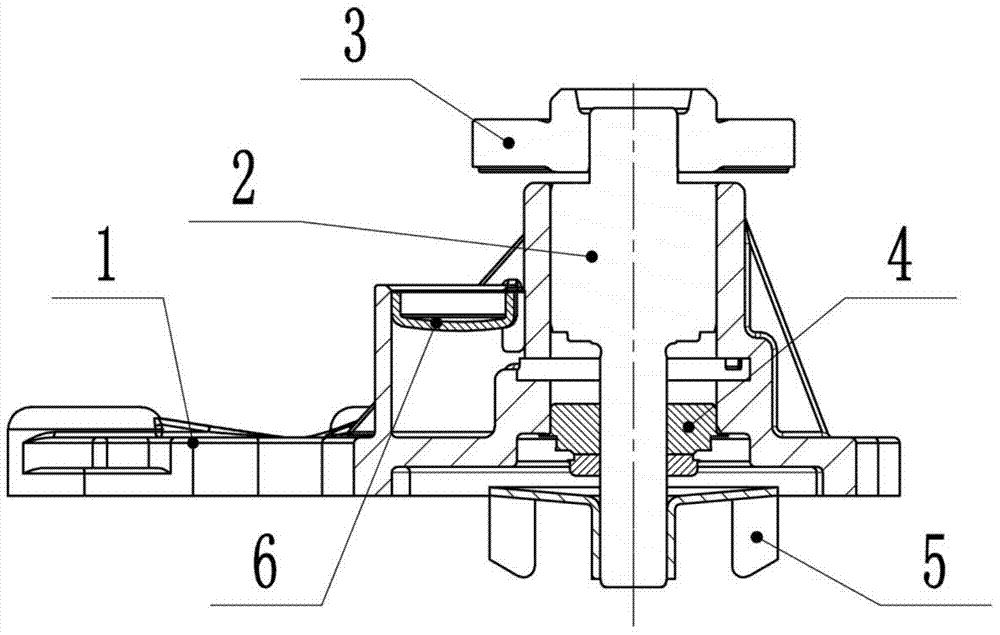

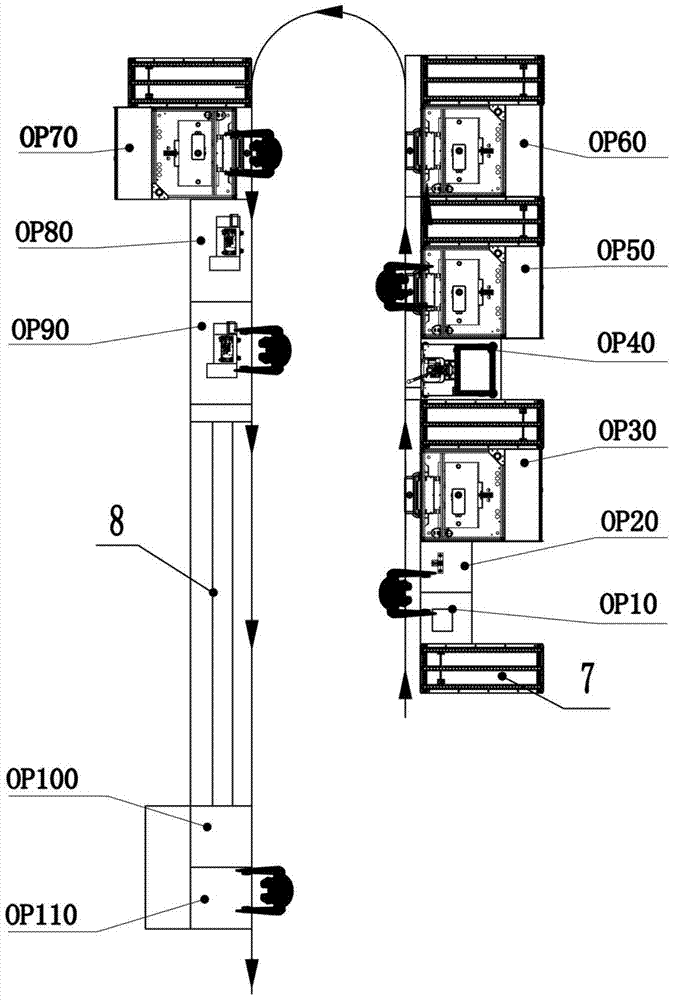

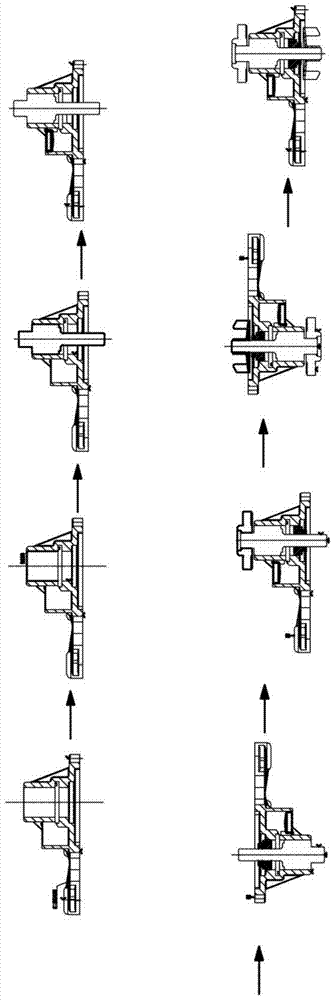

[0068] like Figure 4-7 As shown, a system for automatically assembling a water pump assembly includes a tooling frame 11, an endless automatic belt conveyor line 10, a conveying tray 14, a control mechanism 9, a material path 12 for qualified products and a material path 13 for unqualified products, and a conveying tray 14 Set on the circular automatic belt conveyor line 10, the qualified product material channel 12 and the unqualified product material channel 13 are set at the unloading end of the circular automatic belt conveyor line 10, and the circular automatic belt conveyor line 10 is set inside the tooling frame 11 , the control mechanism 9 is arranged outside the tooling frame 11, and the manual feeding station A1, the image detection station A2, the automatic gluing station A3, the automatic bearing pressing station A4, Automatic plugging cover station A5, automatic water seal assembly station A6, automatic detection water seal assembly station A7, automatic flange p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com