Waste shredding device for blistering machine

A shredding device and waste technology, applied in metal processing and other directions, can solve the problems of large waste collection and difficulty in manual disassembly of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. The specific implementation of the blister machine waste shredding device of the present invention will be further described below in conjunction with the accompanying drawings.

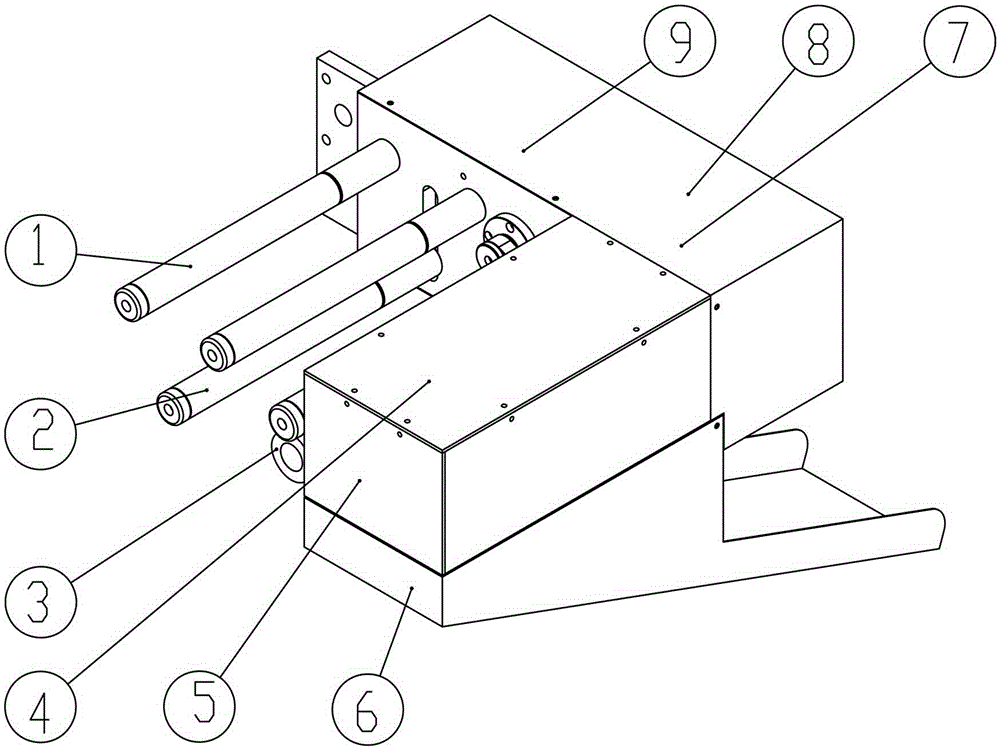

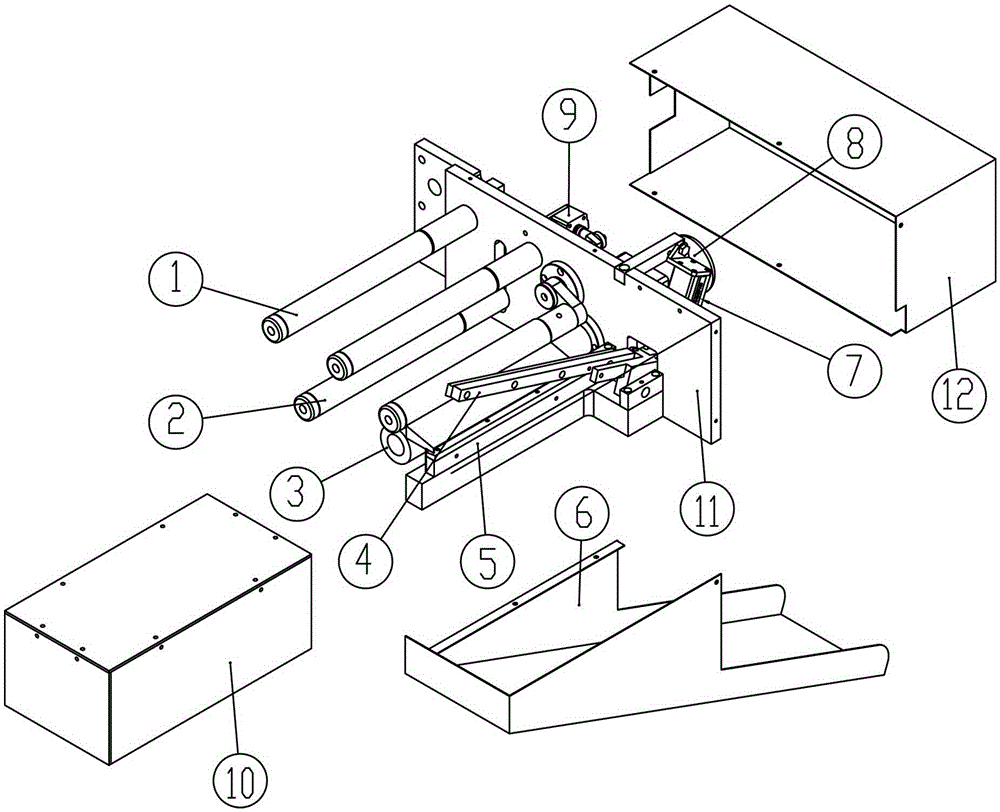

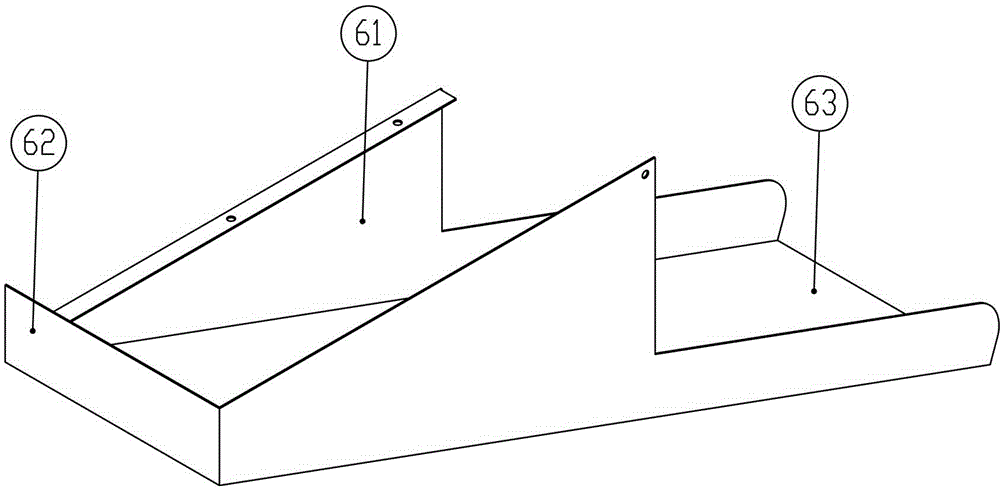

[0028] Such as figure 1 , figure 2 Shown is a schematic structural view of a preferred embodiment of the blister machine waste shredding device according to the present invention. A blister machine waste shredding device of the present invention comprises a housing 12, a driving cutter 4, a driven cutter 5 and a discharge port 6, and the housing 12 is provided with a material cutting cylinder 7 and a traction motor 8 And pressing cylinder 9, traction motor 8 is connected with a plurality of swivel rollers 1 and master control swivel roller 2. After punching by the blister machine, the waste material continuously sent out is wound in an orderly manner by each swivel roller 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com