Water sprayer for silicon wafer cutting machine

A cutting machine and sprinkler technology, applied in chemical instruments and methods, fixed filter element filters, filtration separation, etc., can solve the problems of inconvenient assembly and operation of water spray pipes and drainage frames, and the lack of filtration performance of water spray pipes, etc. , to achieve the effect of convenient assembly and operation and optimization of water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

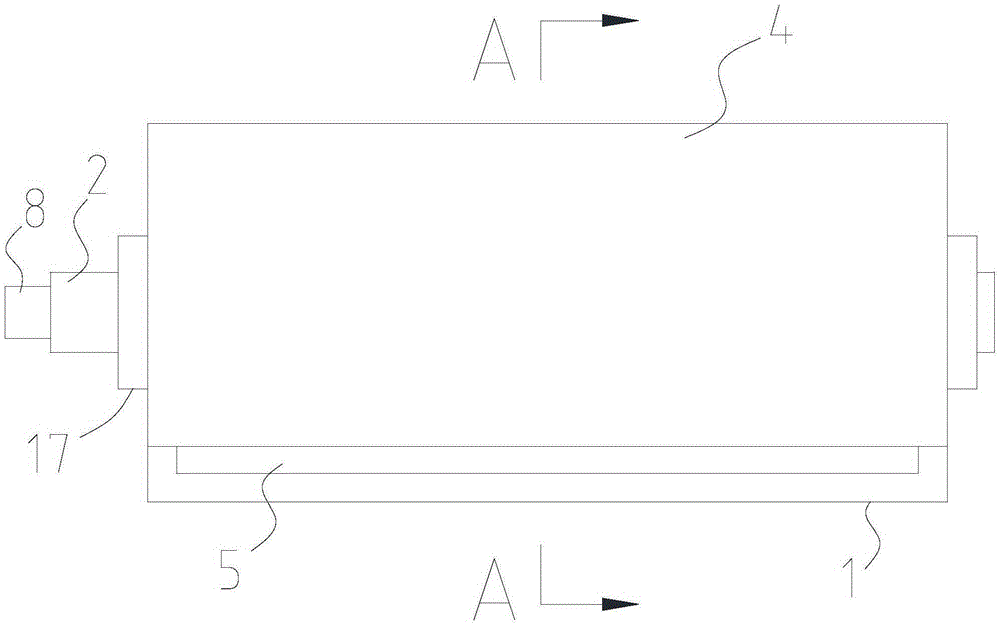

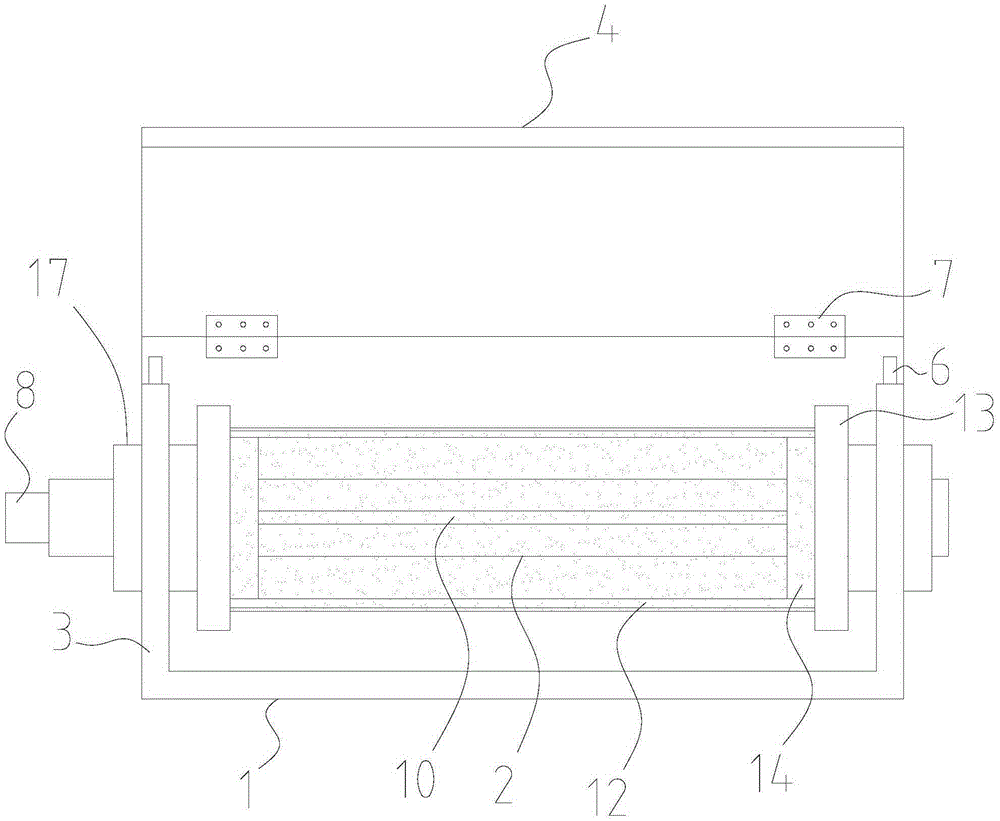

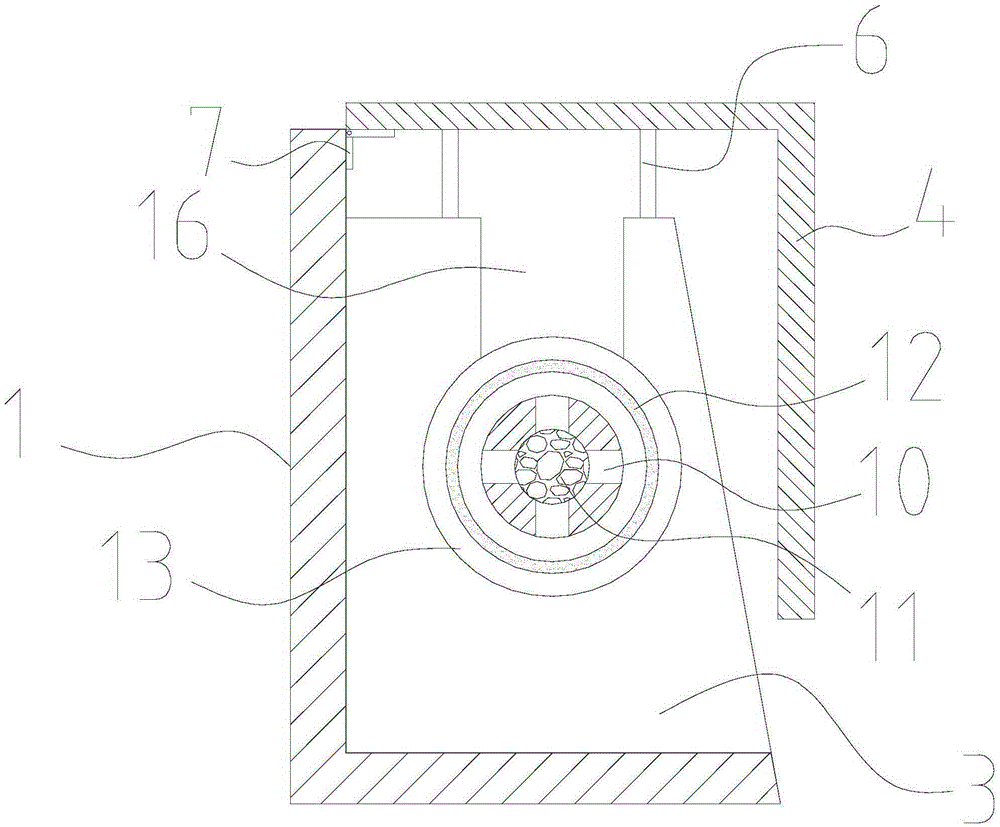

[0018] A water sprayer for a silicon wafer cutting machine of the present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a water sprayer for a silicon wafer cutting machine includes a flow guide frame 1 with an L-shaped cross section, a water spray pipe 2 is fixed on the flow guide frame 1, and two ends of the flow guide frame 1 are respectively arranged There is a support plate 3 for fixing the water spray pipe 2, the support plate 3 and the flow guide frame 1 are of an integrated structure, the flow guide frame 1 is also provided with a cover body 4, and the cover body 4 is fixed on the guide frame by a hinge 7 On the flow frame 1, after the cover body 4 is fixed on the flow frame 1, see image 3 , the cover body 4 and the flow guide frame 1 form a cavity, the water spray pipe 2 is located in the cavity, and a drain port 5 is provided between the cover bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com