Gravity center detecting method, device and system for tower crane and tower crane

A tower crane, center of gravity position technology, applied in the direction of cranes, transportation and packaging, load hanging components, etc., can solve problems such as increasing system costs, and achieve the effect of increasing system costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

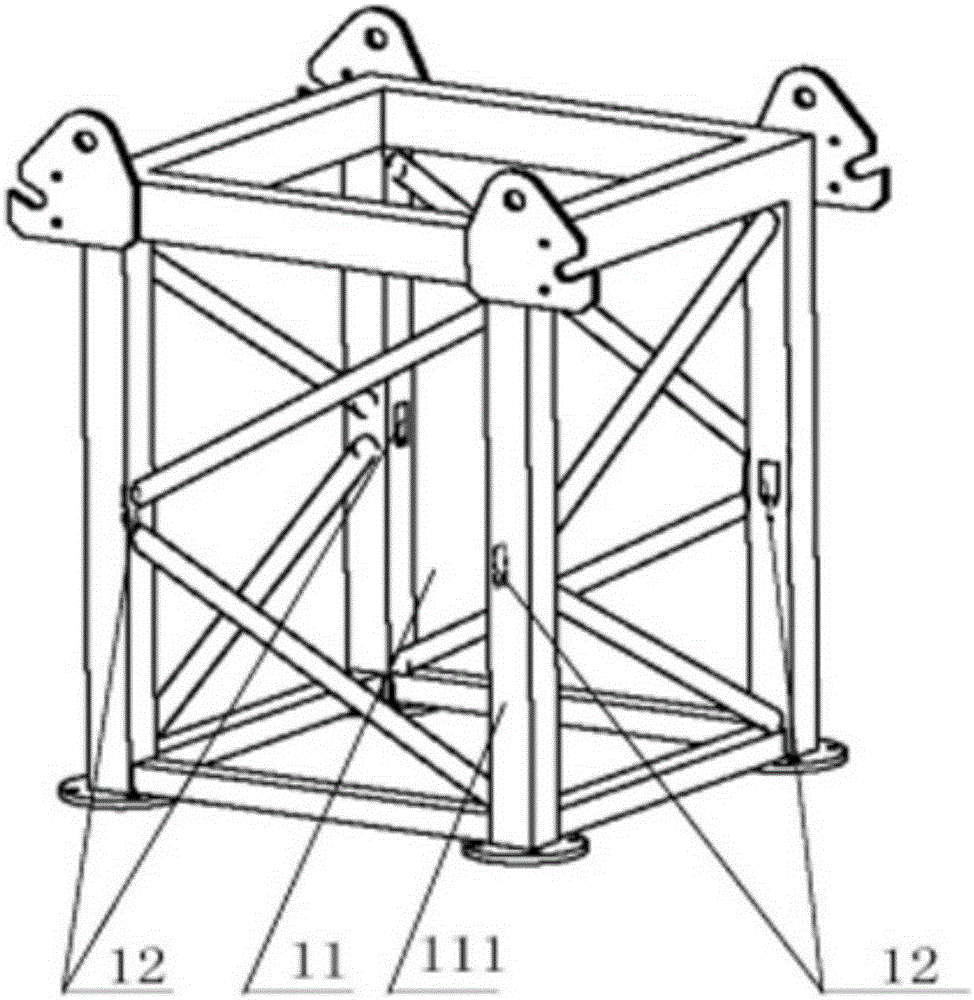

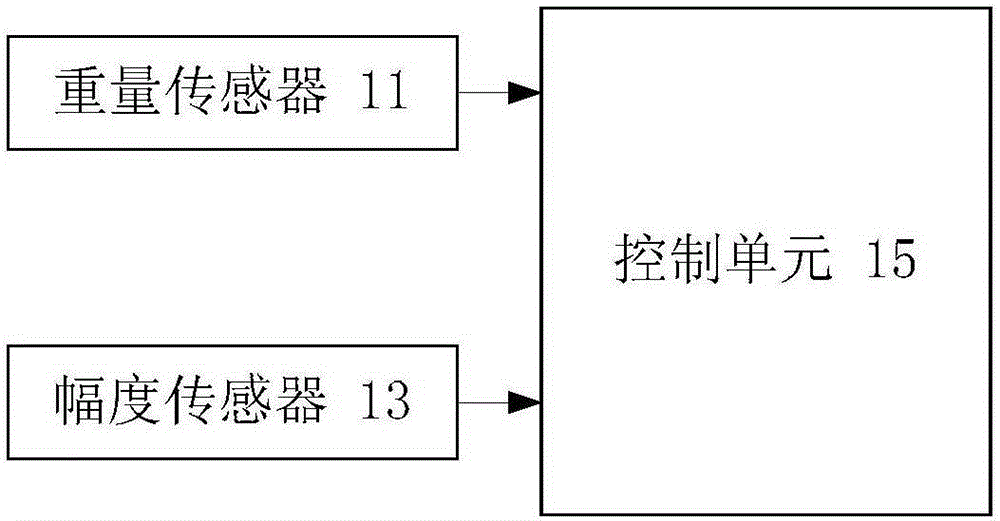

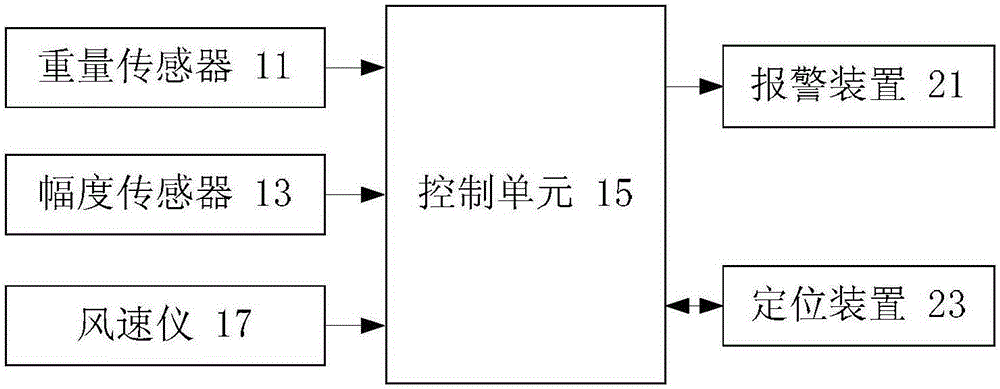

[0045] This embodiment provides a center of gravity detection system of a tower crane, the tower crane includes a boom, a balance arm and a luffing trolley arranged on the boom, such as figure 2 As shown, the system may include: a weight sensor 11 , an amplitude sensor 13 and a control unit 15 .

[0046] Among them, the weight sensor 11 is set on the fixed pulley of the luffing trolley of the tower crane to obtain the quality of the lifting object; the amplitude sensor 13 is set on the drum shaft end of the luffing mechanism of the tower crane to obtain the weight of the lifting object. The arm length from the center of slewing of the tower crane; the control unit 15 is electrically connected to the weight sensor and the amplitude sensor, and is used to determine the center of gravity position of the tower crane according to the obtained quality of the lifting object and the length of the arm.

[0047] Since the weight of the balance arm on the balance arm side of the tower c...

Embodiment 2

[0058] According to an embodiment of the present invention, an embodiment of a method for detecting the center of gravity of a tower crane is provided. It should be noted that the steps shown in the flow chart of the accompanying drawings can be executed in a computer system such as a set of computer-executable instructions, Also, although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

[0059] The tower crane includes a tower body, a rotating tower column, a jib, a balance jib, a luffing trolley set on the jib, a weight sensor set on the fixed pulley of the luffing trolley, and a luffing mechanism set on the tower crane. The shaft end amplitude sensor of the reel, such as Figure 5 As shown, the method includes the following steps:

[0060] Step S12, acquiring the hoisting mass of the hoisted object, wherein the hoisting mass at least includes: the mass of the ...

Embodiment 3

[0116] The embodiment of the present invention also provides a center of gravity detection device of a tower crane. Figure 8 is a schematic structural diagram of a center of gravity detection device for a tower crane according to an embodiment of the present invention. Among them, the tower crane includes a tower body, a rotating tower column, a boom, a balance arm, a luffing trolley arranged on the boom, a weight sensor arranged on the fixed pulley of the luffing trolley, and a weight sensor arranged on the variable amplitude trolley of the tower crane. The amplitude sensor of the drum shaft end of the web mechanism, such as Figure 9 As shown, the center of gravity detection device includes: a first acquisition module 12 , a second acquisition module 14 and a first processing module 16 .

[0117] Wherein, the first collection module 12 is used to obtain the lifting quality of the lifting object, wherein the lifting quality includes at least: the quality of the lifting obje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com