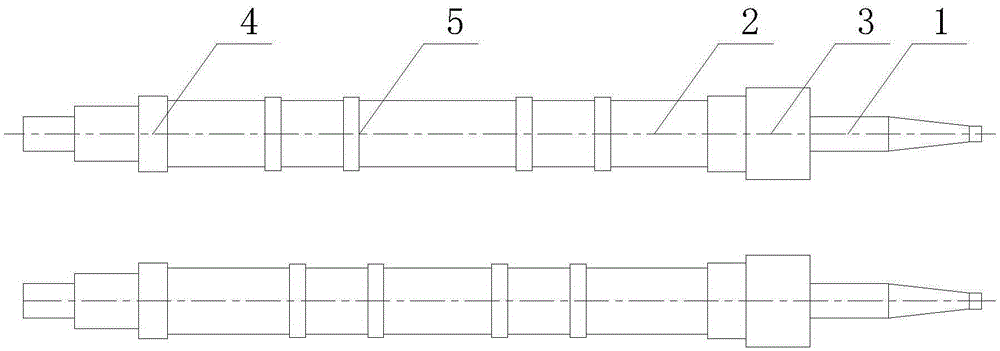

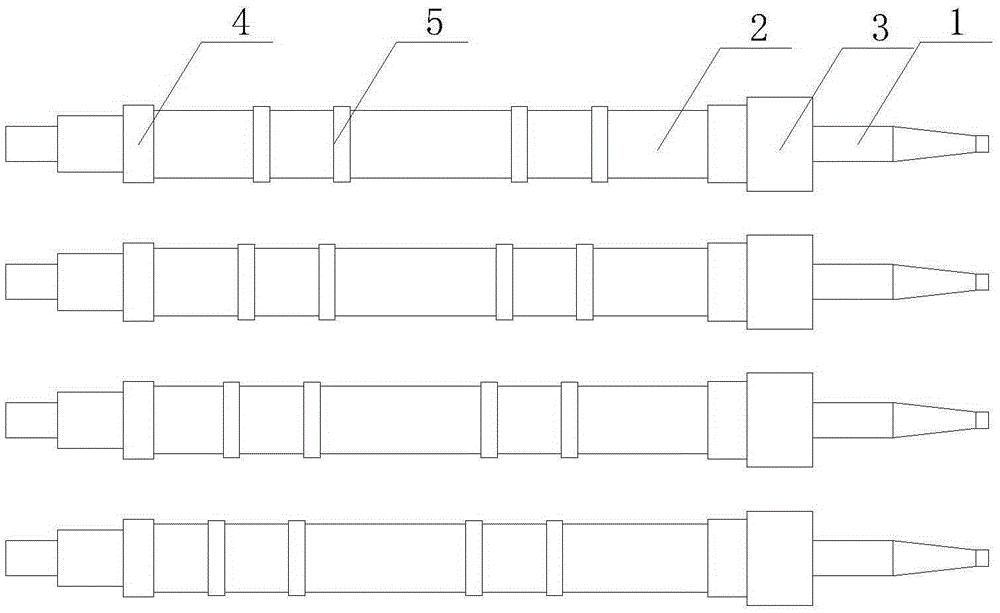

Plate and strip type roll bottom type heating furnace rolls

A roller hearth heating furnace and furnace roller technology, applied in heat treatment furnaces, lighting and heating equipment, furnaces, etc., can solve problems such as slab pits, batch quality accidents, and loss of manufacturers, and achieve the effect of protecting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The arrangement of the roller rings of the furnace rollers will directly affect the traveling track of the slab. For the heating furnace, the tracking of the slab is particularly important. It will cause a major accident and damage the refractory material and furnace body. On January 25, 2014, the online production plan was steel grade SS400, the thickness of the slab was 72mm, and the width of the slab was 1500mm. The use of the invention has greatly improved the traveling state of the slab through practice, and no slab tracking accident has occurred so far.

Embodiment 2

[0020] Due to the slagging of the furnace rolls, the roll body is uneven. When the hot slab passes through, the slagging will cause indentations on the lower surface of the slab, and press into the oxide scale, etc., which seriously affects the product quality of the strip surface during rolling. The characteristics of the CSP production line make it impossible to pull out the furnace rolls for processing online. At this time, the invention can effectively solve this problem and significantly improve the product quality of the lower surface of the strip. The production plan on February 16, 2014 is steel grade Q345B, the thickness of the slab is 57mm, and the width of the slab is 1500mm. During the production of the day, the surface quality of the lower surface of the slab was tracked, and no abnormalities were found, and the quality of the lower surface of the slab was significantly improved compared with the previous one.

Embodiment 3

[0022] On April 28, 2014, SPCC was produced online, the slab width was 1275mm, and the slab thickness was 72mm. Since the steel produced is low-carbon, it is more likely to cause slagging of furnace rollers. Two pairs of slab surface quality tracking on that day have not been found The abnormality of the surface has been significantly improved compared with the previous situation. It can be seen that the invention has a significant effect on different steel types and different slab specifications. After a period of verification, the use and promotion of this invention has significantly improved the service life of the furnace rollers of the two-stream heating furnace. It has effectively reduced the phenomenon of furnace roller slagging, thereby reducing the accident time and the loss of insulation materials when the furnace rollers are replaced. consumption, effectively saving production costs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com