Composite spinning box in three-box form

A composite spinning and spinning box technology, which is applied in the spinning field, can solve the problems of reducing fiber strength and uneven elongation, and the compound spinning box cannot control the temperature of components alone, so as to reduce fiber strength and uneven elongation The rate and apparent viscosity are close to the same, and the effect of improving tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

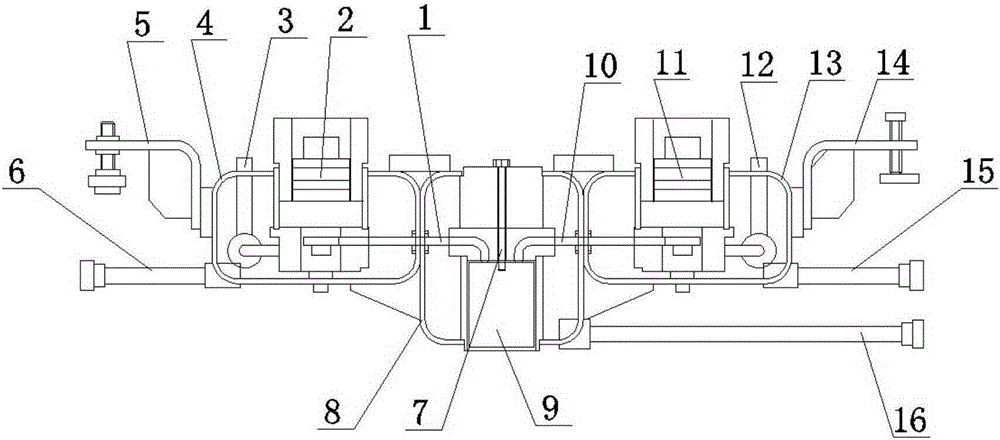

[0026] The embodiment of the present application provides a three-box composite spinning box, which solves or partially solves the technical problem that the composite spinning box in the prior art cannot individually control the temperature of the components. By setting the first spinning box that can independently control the temperature The spinning box, the second spinning box and the main spinning box realize the independent adjustment of the temperature of the two components, so that the apparent viscosity of the two components is close to the same, reducing or eliminating the angle yarn, and ensuring the composite yarn The uniformity of fineness, crystallinity and orientation improves the tensile performance of the composite yarn and reduces the technical effect of fiber strength and elongation unevenness.

[0027] The embodiment of the present application provides a composite spinning box in the form of three boxes, which is used to composite the first component and the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap