Weft knitting air layer double-face faux suede fabric and production method thereof

A production method and air layer technology, applied in the directions of weft knitting, fabric surface trimming, heating/cooling fabric, etc., can solve the problems of limited application, lack of skeleton and stiffness of weft knitted double-faced suede fabric, etc. Long-lasting shape retention, excellent hygroscopicity, and outstanding skeleton feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention provides a weft-knitted air layer double-sided suede fabric and a production method thereof. The product is full and thick, ultra-fine, excellent in moisture absorption, moderate in elasticity, excellent in drape and outstanding in frame.

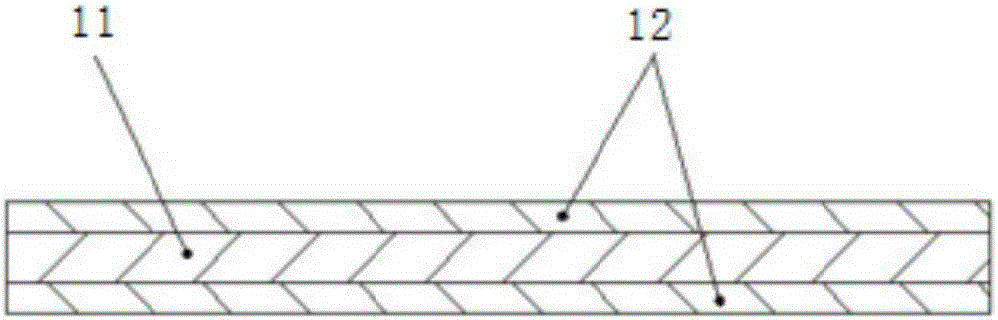

[0021] Reference attached figure 1 The fabric of the present invention mainly includes an intermediate layer 11 and a surface layer 12 separately provided on the upper and lower surfaces of the intermediate layer 11. The intermediate layer 11 is a polyester-nylon composite silk layer, and the surface layer 12 is a sea-island silk layer. Among them, the polyester-nylon composite yarn layer is woven from 52D / 24F polyester-nylon composite yarn, and the sea-island yarn layer is woven from 90dtex / 36F sea-island yarn. The polyester-nylon composite yarn is 100mm long and the sea-island yarn is 114mm.

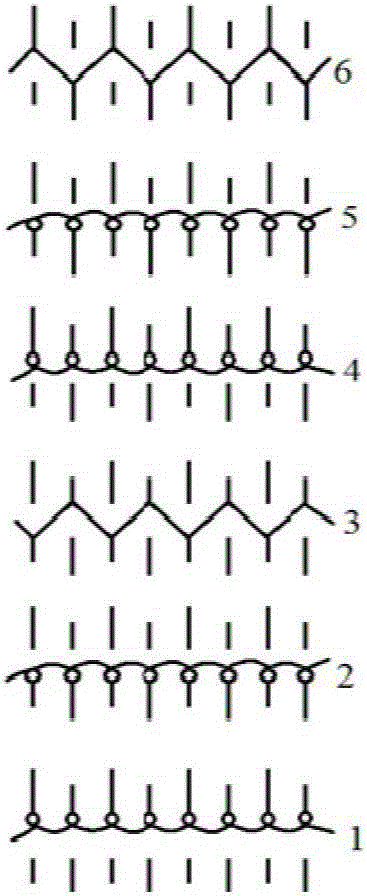

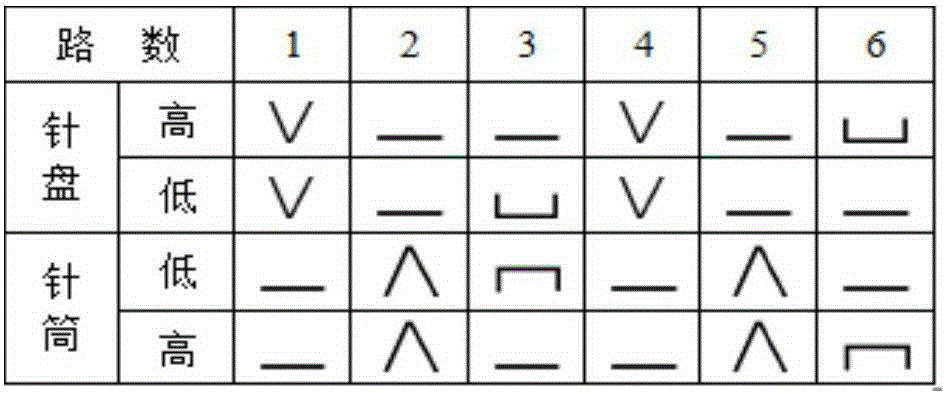

[0022] At the same time, refer to the attached figure 2 And attached image 3 The present invention also includes a method for pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com