Electronic control multi-plate-type self-locking drive axle

A drive axle, multi-piece technology, applied in the field of machinery, can solve the problems of insufficient driving force to overcome driving resistance, accelerate parts wear, waste fuel, etc., achieve good locking and slip-limiting performance, avoid meshing stuck, improve The effect of driving ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

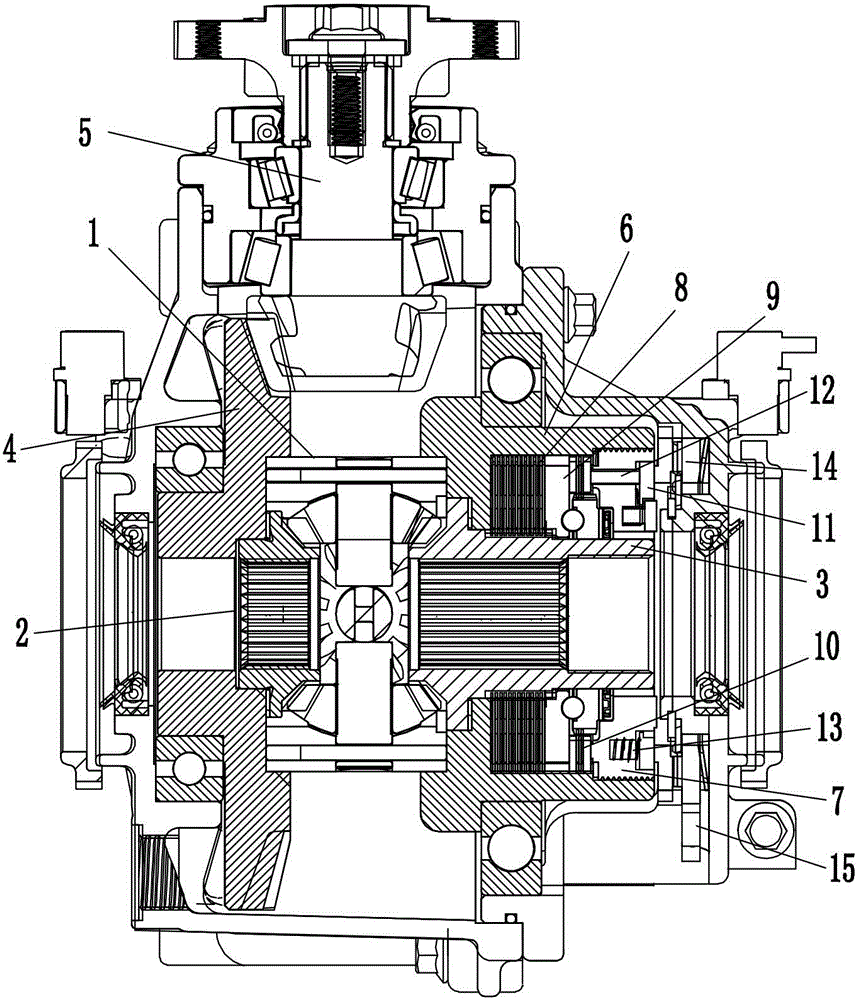

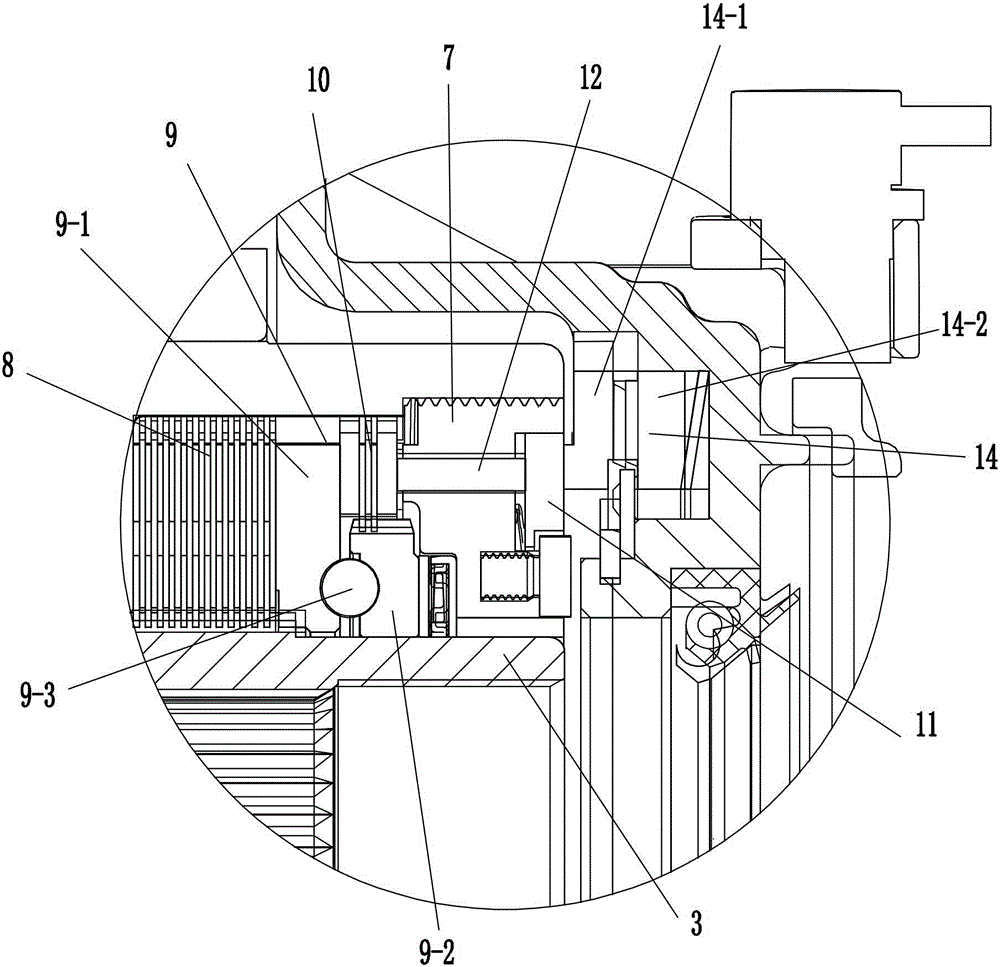

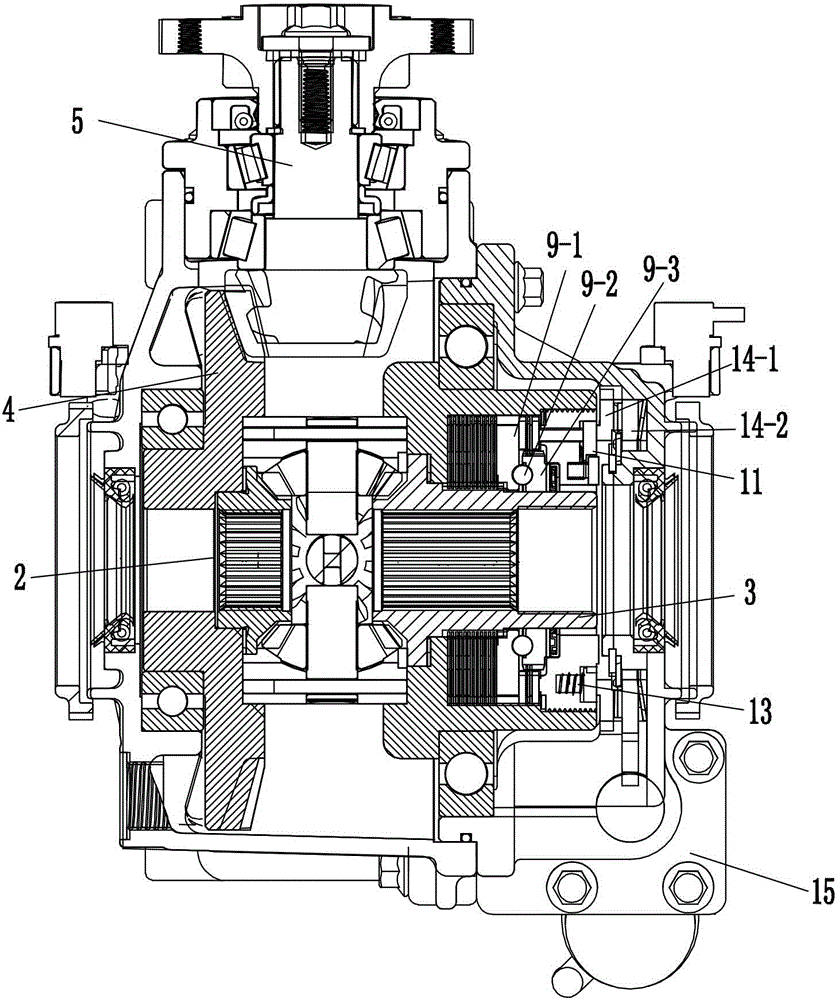

[0034] refer to figure 1 and figure 2As shown, an electronically controlled multi-piece self-locking drive axle described in this embodiment includes a drive axle box body and a drive axle box cover that is fastened on the right side of the drive axle box body. There is a first differential case 1, which is provided with a left side gear 2, a right side gear 3 and a planetary gear, and the first differential case 1 is fixedly connected with The transmission gear 4 is arranged coaxially with the left side shaft gear 2 , and the input gear 5 vertically meshing with the transmission gear 4 is also arranged in the drive axle casing. The right side gear 3 is covered with a cylindrical second differential case 6 and the right end of the second differential case 6 is sealed with a differential case cover 7, the second differential case 6 is connected to the drive The axle case covers are rotatably connected by bearings. The right side gear 3 is coaxially sleeved with a working fr...

Embodiment 2

[0046] refer to Figure 7 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the drive mechanism adopts a push rod motor. Thereby under the state of locking and differential speed, be to rely on the expansion and contraction of electric control push rod motor to give the impetus of relative rotation of the 4th cam.

Embodiment 3

[0048] refer to Figure 8 As shown, an electronically controlled multi-piece self-locking drive axle described in this embodiment includes a drive axle box body and a drive axle box cover that is fastened on the right side of the drive axle box body. There is a first differential case 1, and the left side gear 2, the right side gear 3 and planetary gears are arranged in the first differential case 1, and the first differential case 1 is fixedly connected with the left side gear The side gear 2 is coaxially arranged with a transmission gear 4 , and an input gear 5 vertically meshing with the transmission gear 4 is also provided in the drive axle casing. The right side gear 3 is covered with a cylindrical second differential case 6 and the right end of the second differential case 6 is sealed with a differential case cover 7, the second differential case 6 is connected to the drive The axle case cover is rotatably connected by bearings. The right side gear 3 is coaxially sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com