A Flow Regulating Proportioning Valve and Its Application

A technology of flow regulation and proportioning valves, applied in the direction of valve details, multi-way valves, valve devices, etc., can solve problems such as prone to failure, valve core and pipeline blockage, cost a lot of manpower and material resources, and achieve non-linear adjustment problems Simplify, ensure operation accuracy, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

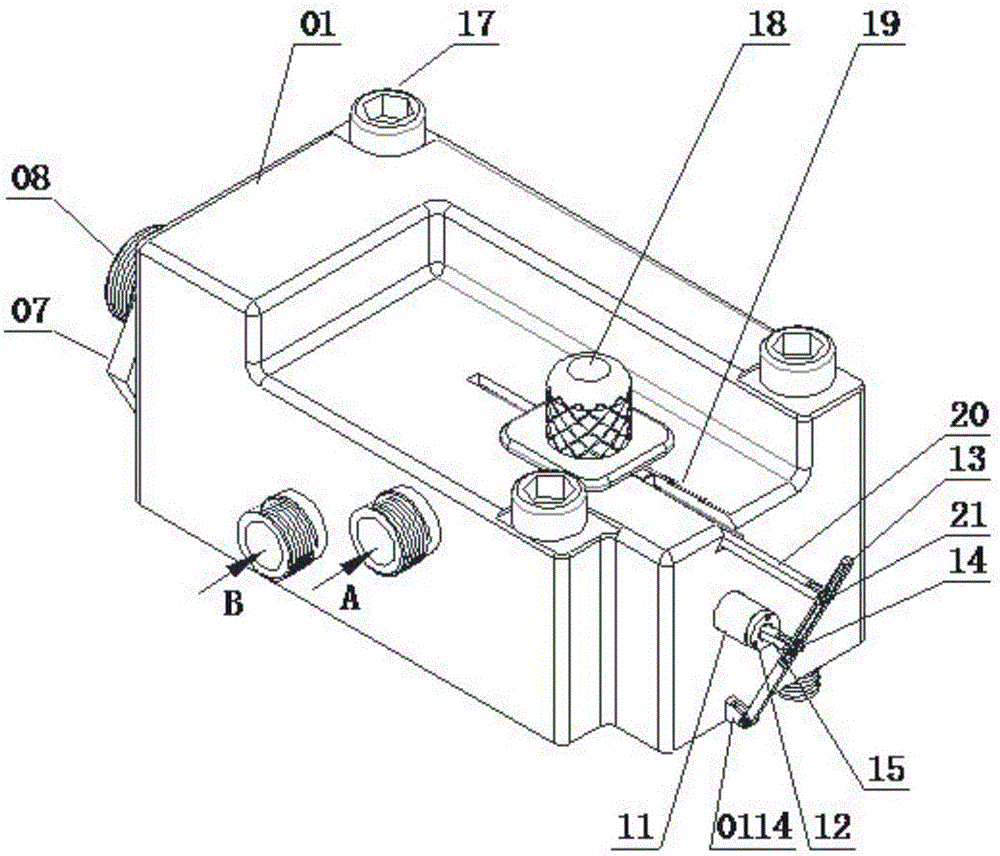

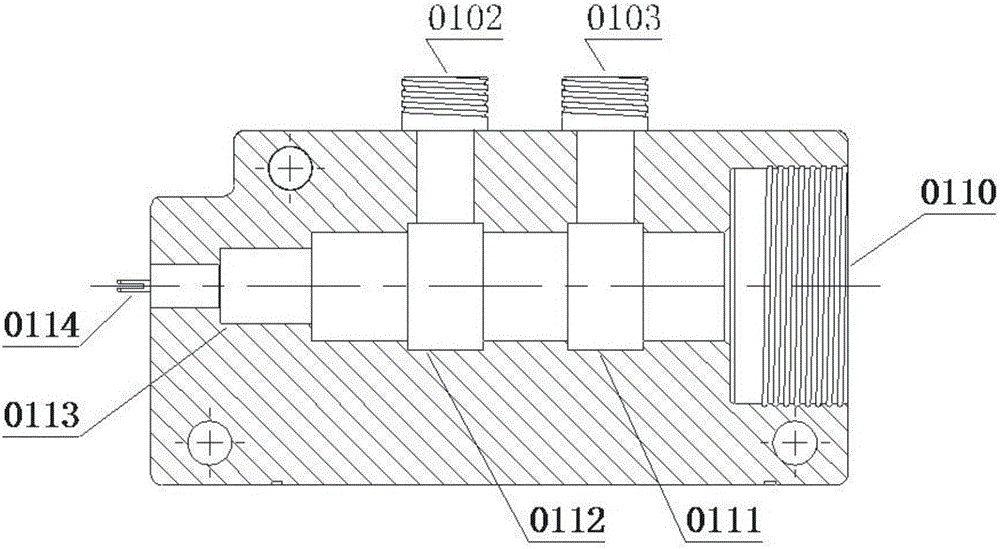

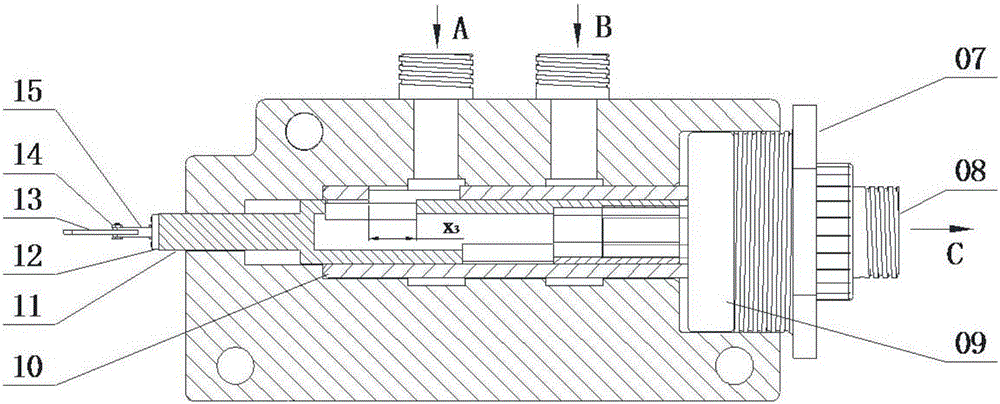

[0051] A flow adjustment proportioning valve, comprising a housing 01, a valve cavity is provided in the housing 01, and the A fluid inlet 0102, the B fluid inlet 0103 and the mixed fluid C are opened on the housing 01 and communicated with the valve cavity. Outlet; a central valve body 10 is arranged in the valve cavity, and a central valve core 11 is arranged in the central valve body 10. The central valve core 11 includes a mixing chamber 1104, and one end of the mixing chamber 1104 communicates with the outlet of the mixed fluid C, and the central valve body 10 is provided with an A valve body inlet 1001 and a B valve body inlet 1002, and the central valve core 11 is provided with an A valve core inlet 1101 and a B valve core inlet 1102 respectively matched with the A valve body inlet 1001 and the B valve body inlet 1002 , and both the A spool inlet 1101 and the B spool inlet 1102 communicate with the mixing chamber 1104, and the A spool inlet 1101 and the A valve body inle...

Embodiment 2

[0057] A flow regulating proportional valve, the structure is as described in Embodiment 1, the difference is that: the flow regulating proportional valve also includes an adjusting lever 13, one end of the central valve core 11 protrudes from the housing and is provided with a rotary joint 12, The swivel joint 12 is hinged to the adjustment lever 13 through the fork 15 of the small arm, and the bottom end of the adjustment lever 13 is hinged to the lever fulcrum 0114 on the housing 01 .

[0058] The upper part of the adjustment lever 13 is also hinged with a large arm shift fork 20, which is embedded in the housing 01 and can move in the housing. A flow adjustment scale 19 is arranged on the side of the boom shift fork 20 on the housing. Through the combination of the flow adjustment scale 19 and the arm shift fork 20, the linear displacement of the adjustment central valve core 11 can be observed intuitively, and the displacement of the central valve core can be adjusted conv...

Embodiment 3

[0061] This embodiment provides a method for using the flow regulating proportional valve as described in Embodiment 2, which includes the following steps,

[0062] (1) Two solutions A and B with equal pressure, solution A is input into the housing 01 through the A fluid inlet 0102, and solution B is input into the housing 01 through the B fluid inlet 0103;

[0063] (2) The solution A continues to flow into the central inlet 0112 of A, and passes through the rectangular cross-sectional area S formed by the two rectangular valve ports of the A valve body inlet 1001 and the A valve core inlet 1101 A After entering the mixing chamber 1104, it is output through the output threaded joint 0802 at the right end of the proportioning adjustment handle 08; the solution B continues to flow into the B center inlet 0111, and passes through the rectangular valve port formed by the B valve body inlet 1002 and the B valve core inlet 1102 Flow cross-sectional area S B , enter the mixing chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com