Acoustic measuring method of thickness of ice layer

A technology of ice layer thickness and measurement method, applied in the direction of measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc., can solve poor measurement results, inability to monitor sea ice thickness in a wide range, real-time and accurately, implementation and operation difficulties and other problems to achieve the effect of overcoming measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

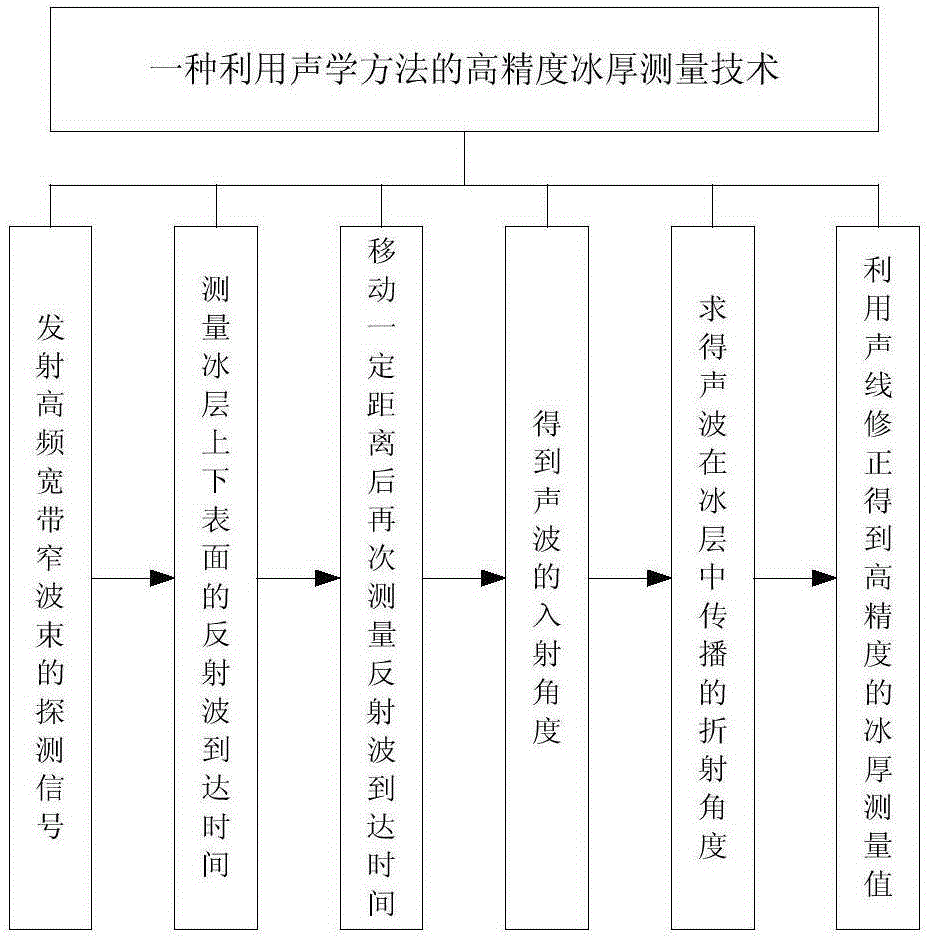

[0033] combine figure 1 , the implementation steps of the high-precision ice thickness measurement technology of the present invention are as follows:

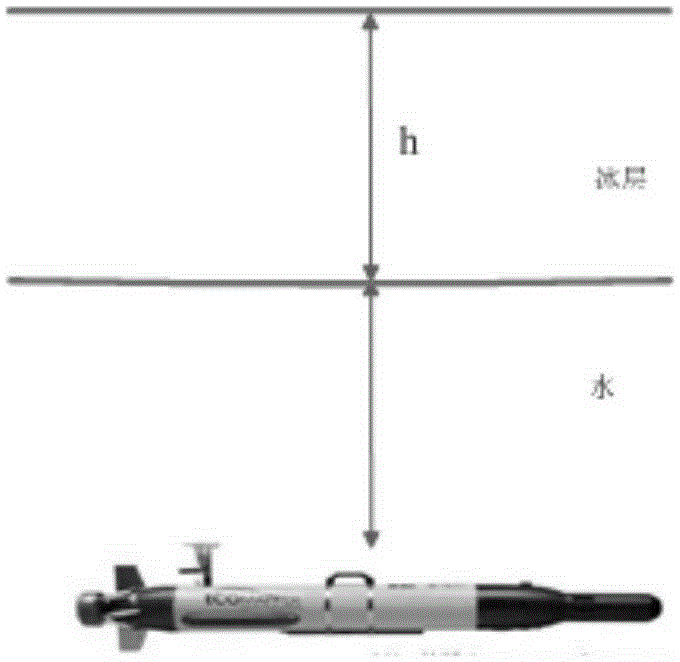

[0034] (1) The ice measuring instrument continuously transmits high-frequency, wide-band, and narrow-beam detection signals, and the time interval between signals is Δt.

[0035] (2) Measure the arrival time t of the reflected wave on the lower surface of the ice layer (ice-water interface) 1 , and the arrival time t of the upper surface of the ice layer (ice-air interface) 2 , then the time delay difference of the ice layer thickness at this time is τ 1 = t 2 -t 1 .

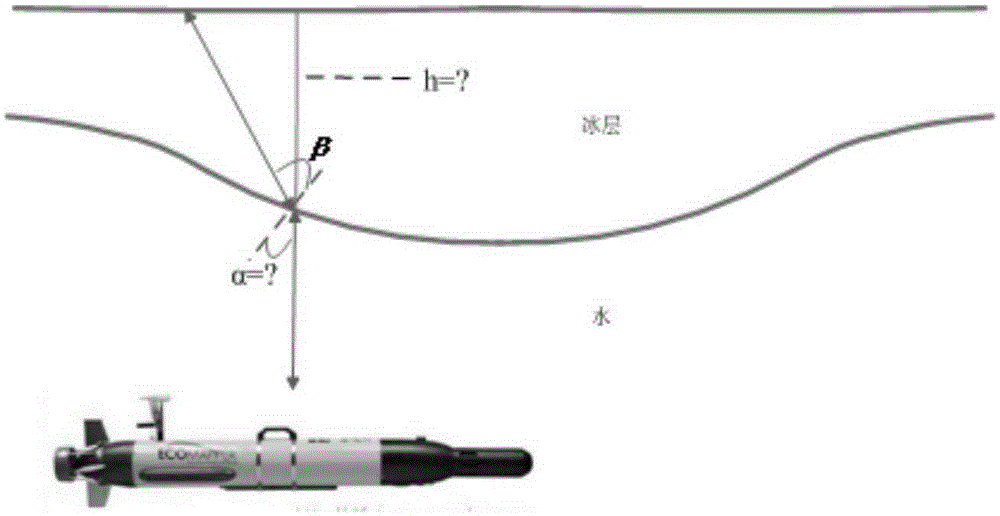

[0036] (3) The underwater carrying platform of the ice measuring instrument (such as underwater AUV, etc.) moves at a constant speed v, and after moving a distance of v×Δt, the arrival time t of the emitted wave on the surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com