Metal Young modulus system based on photoelectric sensor

A photoelectric sensor, Young's modulus technology, applied in the fields of material science and optical communication, can solve the problems of difficult measurement, cumbersome operation, long time consumption, etc., and achieve the effect of automation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

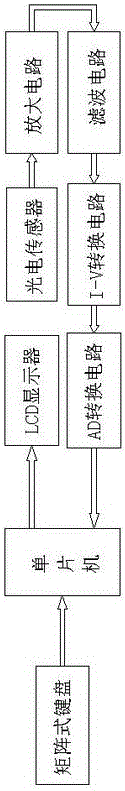

[0017] The metal Young's modulus system based on the photoelectric sensor can convert the displacement change during the metal Young's modulus test into the change of the corresponding current signal by means of photoelectric conversion, and then process it through the single-chip microcomputer and realize real-time automatic measurement , data processing and display, so as to achieve the automation and high precision of Young's modulus measurement, such as figure 1 As shown, the following structure is particularly provided: including a single-chip microcomputer, a signal conditioning circuit and a photoelectric conversion circuit, the single-chip microcomputer is connected to the signal conditioning circuit, and the signal conditioning circuit is connected to the photoelectric conversion circuit.

Embodiment 2

[0019] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, such as figure 1 As shown, the following structure is particularly provided: the signal conditioning circuit is provided with an AD conversion circuit, an I-V conversion circuit and a filter circuit, the photoelectric conversion circuit is connected to the filter circuit, the filter circuit is connected to the I-V conversion circuit, and the I-V The conversion circuit is connected to the AD conversion circuit, and the AD conversion circuit is connected to the single-chip microcomputer.

Embodiment 3

[0021] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, such as figure 1 As shown, the following structure is particularly provided: the photoelectric conversion circuit includes a photoelectric sensor and an amplifying circuit, the photoelectric sensor is connected to the amplifying circuit, and the amplifying circuit is connected to a filter circuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com