Cable joint

A technology of cable joint and semi-conductive tape, applied in the direction of cable joint, etc., can solve the problems of shortening the service life of the cable, complicated installation structure, low structural strength, etc., and achieve the effect of preventing short circuit, high structural strength, convenient and reliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

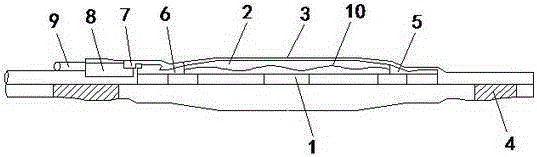

[0014] refer to figure 1 As shown, a cable joint includes a conductor connecting pipe 1, an insulator 2, a shielding mesh casing 3 and a water blocking tape 4, and the conductor connecting pipe 1, the insulator 2 and the shielding mesh casing 3 are arranged from the inside to the outside in sequence, The water blocking tape 4 is arranged at both ends of the shielding net casing 3, and a semi-conductive tape 5 is provided at one end of the insulator 2, and the semi-conductive tape 5 is wound on the outside of the conductor connecting pipe 1, and the other end of the insulator 2 is provided with a The sheath adhesive clip 6 and the ball spring 7 are used to connect the conductors in the cable through the conductor connecting pipe 1, the sheath adhesive clip 6 and the ball spring 7 are attached to the cable, and the holder 8 is clamped , keep the installation firm, the sheath bonding clip 6 is arranged on the outside of the ball spring 7, a clamper 8 is provided on one side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com