Integral self-learning oil recovery controller of motor direct drive beam pumping unit

A beam pumping unit, self-learning technology, applied in the estimation/correction of motor parameters, etc., can solve the problems of low motor power factor, low system efficiency, increased power supply line loss, etc. Maintenance time, simple system structure, effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The integral self-learning oil production controller of the motor direct-driven beam pumping unit of the present invention will be further described below in conjunction with the accompanying drawings:

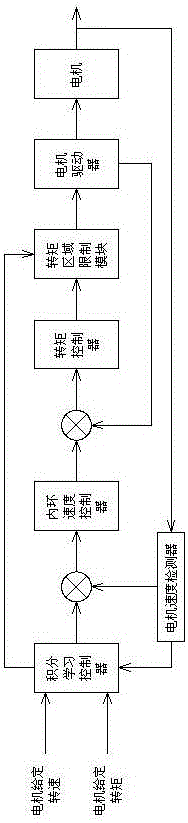

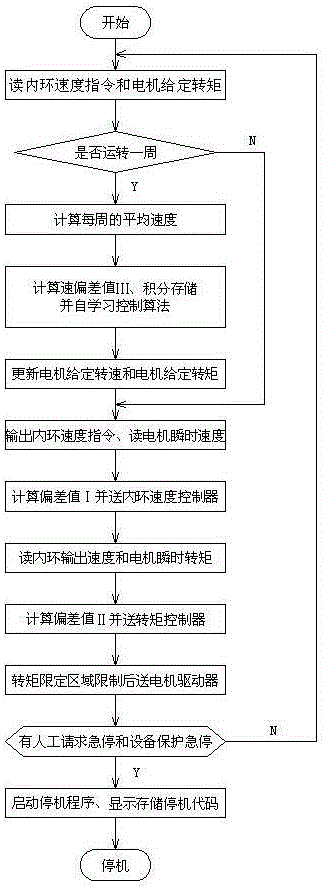

[0026] Such as figure 1 As shown, the motor direct-drive beam pumping unit integral self-learning oil recovery controller of the present invention is composed of an integral learning controller, an inner loop speed controller, a torque controller, a torque region limiting module, a motor driver, a motor Composed of a motor speed detector, the integral learning controller, the inner loop speed controller, the torque controller, the torque area limiting module, the motor driver and the motor are sequentially connected in a circuit, and the motor speed detector is respectively connected with the integral learning controller, the inner loop The speed controller is connected with the motor circuit, and the integral learning controller is connected with the torque area limiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com