End effector assisting in clamping endoscope in minimally invasive surgery

An end effector and minimally invasive surgery technology, applied in the field of minimally invasive surgery medical equipment, can solve the problems of complex structure, easy to produce movement interference, heavy weight of clamping endoscope, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

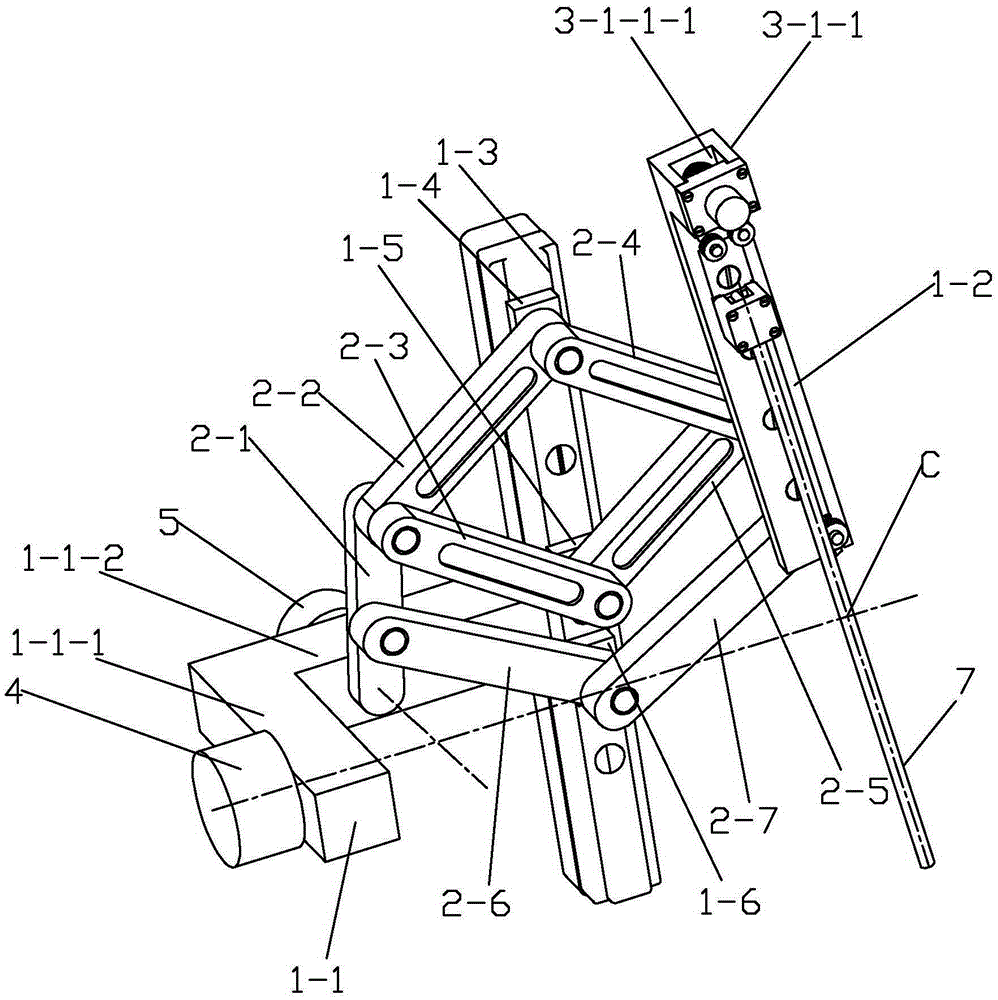

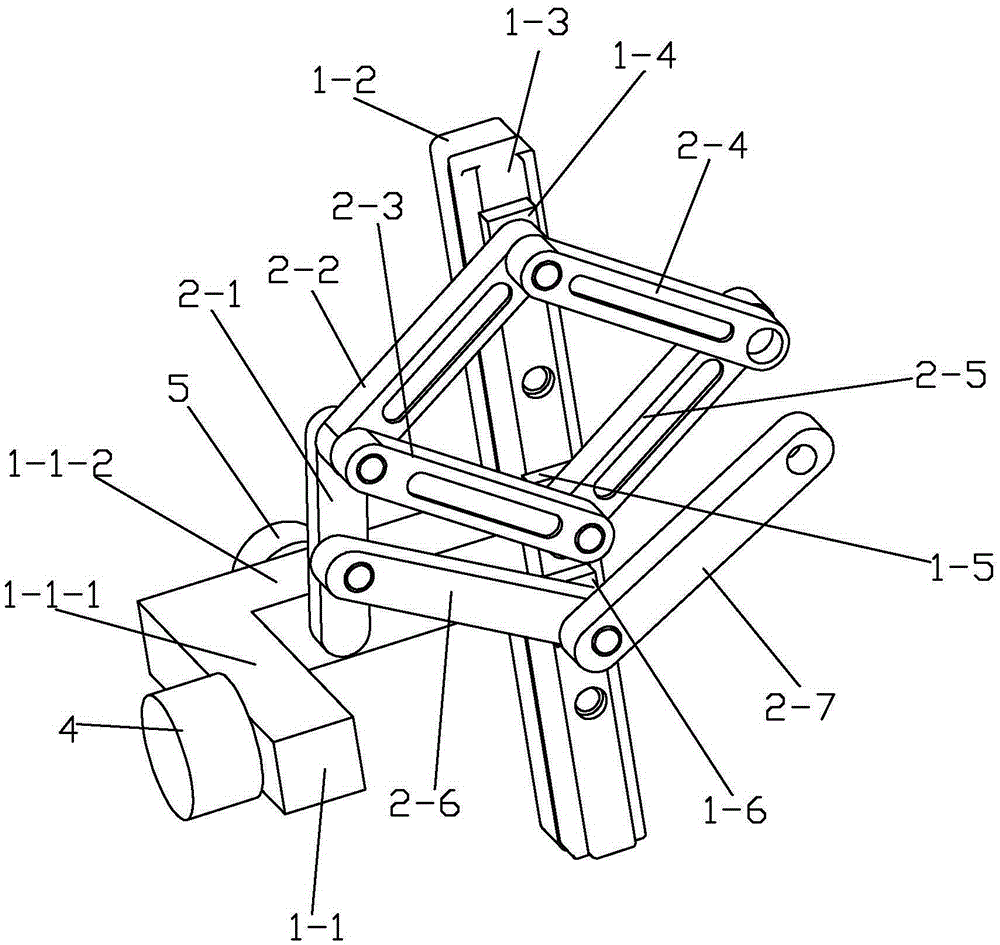

[0022] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 This embodiment is described. An end effector for clamping an endoscope in assisting minimally invasive surgery in this embodiment includes a base, a symmetrical body, an end telescopic body, a first reducer 4, a second reducer 5 and a second reducer. Three reducers 6, the base includes a frame 1-1, a column 1-2, a first linear guide 1-3, a first slider 1-4, a second slider 1-5 and a third slider 1-6, the frame 1-1 is L-shaped and placed horizontally, the column 1-2 is vertically installed on the end face of the long side 1-1-2 of the frame 1-1, and the end face of the column 1-2 along its length direction The first linear guide rail 1-3 is provided, and the first slider 1-4, the second slider 1-5 and the third slider 1-6 are sequentially arranged in the first linear guide rail 1-3 from top to bottom , t...

specific Embodiment approach 2

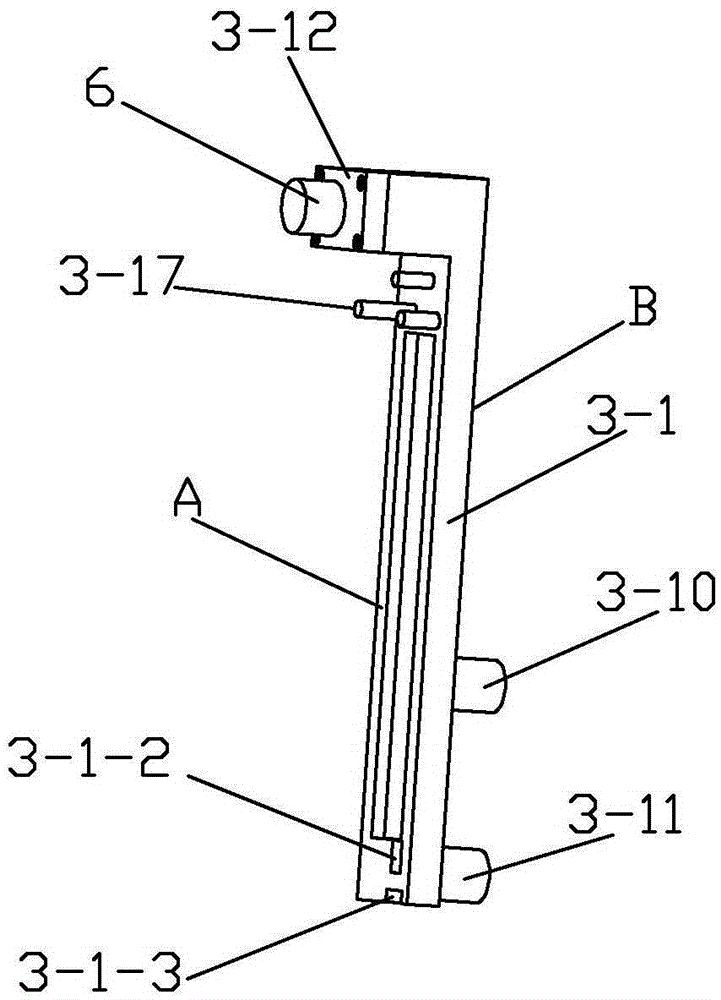

[0027] Specific implementation mode two: combination figure 1 with Figure 5 To illustrate this embodiment, a protrusion 3-1-1 is provided on the end face A of the telescopic body 3-1 in this embodiment near the first guide wheel 3-6, and the upper end face of the protrusion 3-1-1 A mounting groove 3-1-1-1 is provided along its height direction, and the mounting groove 3-1-1-1 is arranged through the length direction of the telescopic body 1, and the ball spline pair 3-3 is arranged in the mounting groove 3-1 -1-1 within. Such arrangement ensures that the ball spline pair 3-3 and the endoscope tool holder 3-4 are on the same plane. Other compositions and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0028] Specific implementation mode three: combination Figure 4 with Figure 5 Describe this embodiment, the ball spline pair 3-3 in this embodiment includes a ball spline shaft 3-3-1, an outer cylinder 3-3-2, a connecting key 3-3-3 and a wire cylinder 3-3- 4. One end of the ball spline shaft 3-3-1 is vertically inserted into the installation groove 3-1-1-1, and the other end of the ball spline shaft 3-3-1 is connected to the third reducer 6 through the coupling The outer wall of the ball spline shaft 3-3-1 is fixed with an outer cylinder 3-3-2, and the outer wall of the outer cylinder 3-3-2 is covered with a wire cylinder 3-3-4. The drum 3-3-2 is connected with the wire drum 3-3-4 through the connection key 3-3-3, and the steel wire 3-5 is wound on the wire drum 3-3-4. In this way, when the third speed reducer 6 drives the ball spline shaft 3-3-1 to rotate, the wire drum 3-3-4 can move linearly up and down along the axis of the ball spline shaft 3-3-1, Ensure that the in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com