Countercurrent extraction device

A countercurrent extraction and extraction tube technology, applied in solid solvent extraction and other directions, can solve problems such as poor uniformity, reduced equipment cost performance, blockage, etc., and achieve the effect of exerting efficiency and improving cost performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

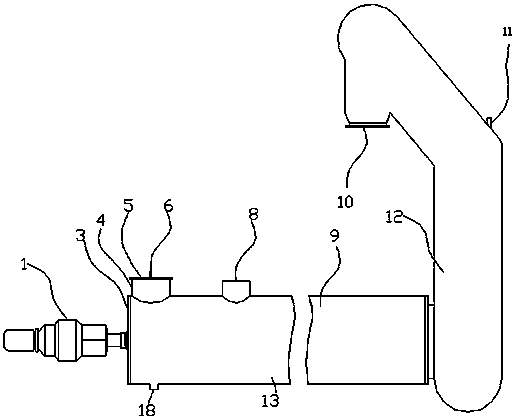

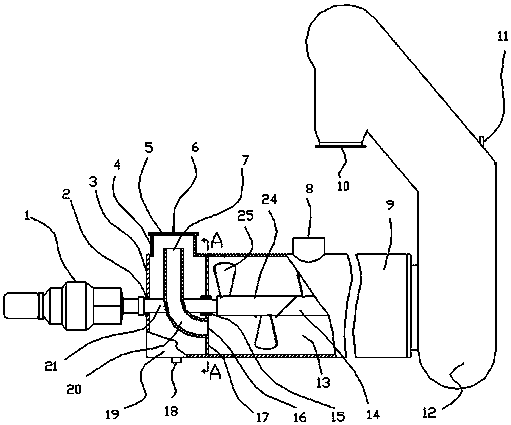

[0020] Embodiment 1: as Figure 1-2 Shown, a kind of countercurrent extracting device, it comprises extraction tube 9, is provided with propeller 14 in extraction tube 9, and propeller 14 is made of shaft 24 and vane 25, and described vane 25 is sheet shape, and described vane 25 is on shaft The surfaces of 24 are arranged side by side and at intervals along the axial direction, such as Figure 6-9 and 14-16, the blades 25 are all located on one side of the shaft 24 in a row or as Figure 10-13 As shown in 17-19, the blades 25 are distributed on the upper part and the lower part of the shaft 24 and arranged in two rows, and the blades on the upper part and the blades on the lower part are alternately arranged.

[0021] Such as Figure 6 , 7, 10, and 11 show that the blade 25 has a wide blade end and a narrow blade root, and the blade root is directly connected to the shaft 24, and the centerline of the blade 25 is perpendicular to the shaft 24 centerline.

[0022] Such as ...

Embodiment 2

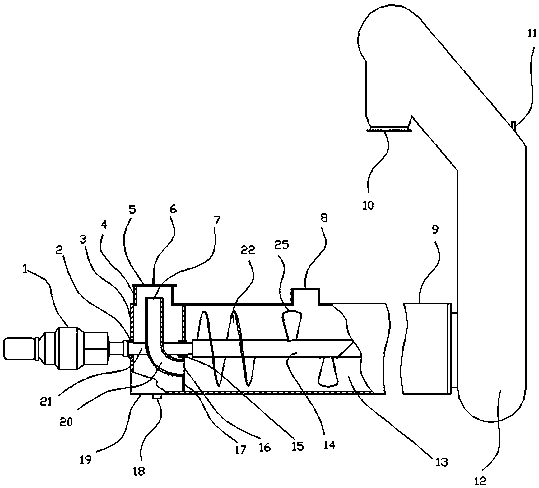

[0025] Embodiment 2: The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference is that image 3 As shown, the blades of the propeller 14 between the baffle plate 17 and the feed inlet 8 can be continuous belt blades 22 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com