Esterification apparatus

The technology of esterification and esterification kettle is applied in the field of alcoholization reaction equipment of plasticizers, which can solve the problems of inability to add materials, and achieve the effects of convenient feeding, uniform stirring, and scientific and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

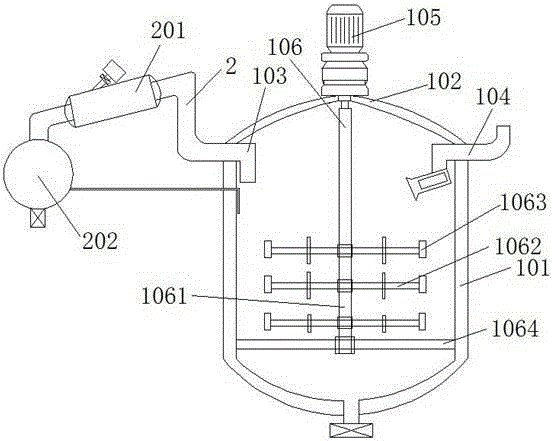

[0019] Embodiment one: if figure 1 As shown, the esterification device includes an esterification kettle 1 and a vacuum feeding device 2. The esterification kettle 1 includes a kettle body 101 and a kettle cover assembly 102. The kettle body 101 is an integrally formed structure, and the kettle body 101 is provided with a feed inlet- 103 and feed port 2 104 are close to the lid assembly 102, feed port 1 103 and feed port 2 104 are symmetrical along the axis of the kettle body 101, feed port 2 104 is provided with an ultrasonic atomizer, and feed port 1 103 is connected with a vacuum feeding device 2, and the vacuum feeding device 2 includes a gas phase / liquid phase converter 201 and a liquid phase liquid separator reflux device 202; the feed port one 103 is connected with a gas phase / liquid phase converter 201 and a liquid phase liquid separator in sequence The reflux device 202, the gas / liquid phase converter 201 is connected with a vacuum device; the kettle body 101 is fixed...

Embodiment 2

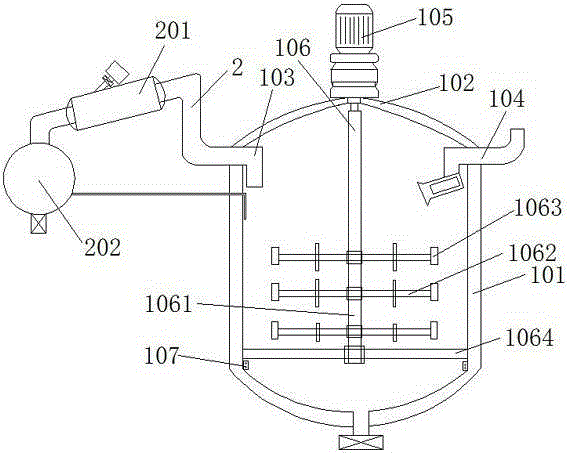

[0020] Embodiment two: if figure 2 As shown, the difference from Example 1 is that an exhaust device 107 is also provided on the inner wall of the kettle body 101 of the esterification device, specifically: the esterification device includes an esterification kettle 1 and a vacuum feeding device 2, and the esterification kettle 1 includes a kettle body 101 and a kettle cover assembly 102. The kettle body 101 is an integrally formed structure. The second feed port 104 is symmetrical along the axis of the kettle body 101, the second feed port 104 is provided with an ultrasonic atomizer, the first feed port 103 is connected with a vacuum feeding device 2, and the vacuum feeding device 2 includes a gas / liquid phase converter 201 and liquid phase liquid separator reflux device 202; feed port one 103 is connected with gas phase / liquid phase converter 201 and liquid phase liquid phase separator reflux device 202 in turn, and is connected with vacuum device on gas phase / liquid phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com