Deformation-preventive welding process for end plates of steel structure roof truss

A welding process and steel structure technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as roof truss beams and column end plates that are prone to deformation, improve overall structural strength, prevent serious deformation, and save construction. Effects of cost and construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

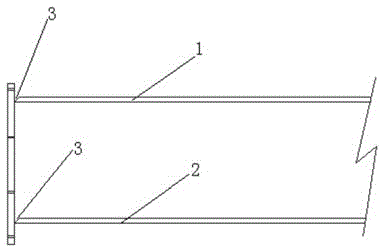

[0015] Referring to the accompanying drawings, the welding process for anti-deformation of the end plate of the steel structure roof truss includes the following construction steps:

[0016] a. In the assembly process, when the upper and lower wing plates 1 and 2 open the breach 3, keep the direction of the groove consistent, and the angle of the groove is controlled at 30-40°;

[0017] b. In the welding process, the diameter of the welding wire is Φ1.2mm; the welding current is 280A; the welding voltage is 32V; the gas flow rate is 20ml / min. The specific construction sequence is as follows:

[0018] ① Weld the triangle plate of the upper wing plate 1 fully first;

[0019] ②The grooves of the upper and lower flanges should be primed. When the thickness of the flanges is >16mm, multi-layer and multi-pass welding methods should be adopted. After each welding, the welding slag spatter should be cleaned before the second welding can be welded to ensure penetration Welding require...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com