Three-primary-color printer and printing method

A three-primary color, 3D printer technology, applied in the field of 3D printing, can solve problems such as the inability to restore colors, and achieve the effect of simple structure, satisfying color requirements, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

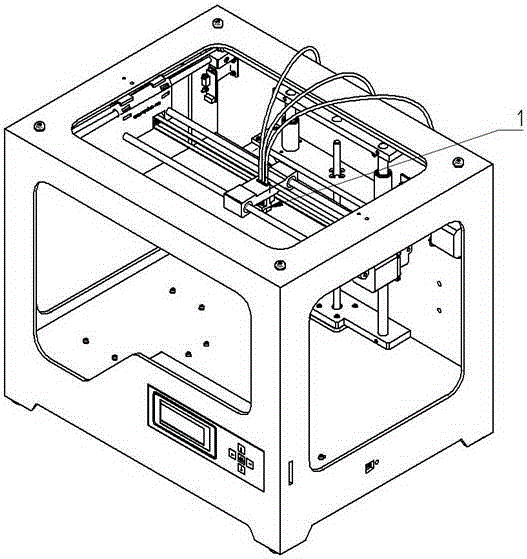

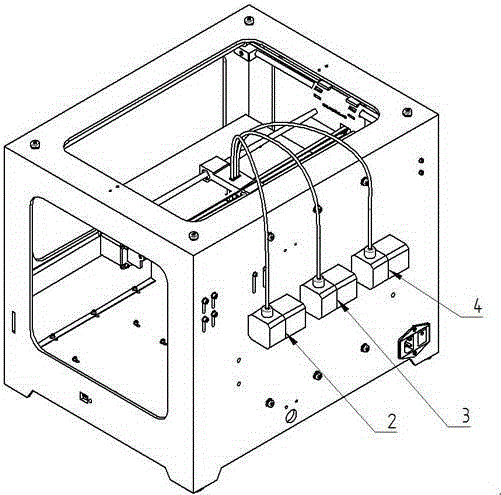

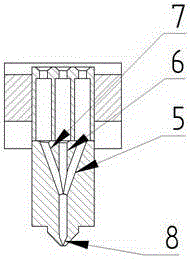

[0021] Such as figure 1 , figure 2 As shown, the printer of the present invention includes an external frame and a print head 1 arranged in the frame. The structure of print head 1 is as follows image 3 As shown, there are three consumable material channels 5, 6 and 7, and the lower end of the three consumable material channels is the discharge channel 8.

[0022] The 3 consumable channels are connected to 3 wire feeding motors A, B, C, driven by the printer program instructions, and the wire is fed in proportion, and the 3 consumables enter figure 1 In the shown print head 1, the consumables are softened in the respective consumable channels 5, 6 and 7, and then enter the mixing channel 8 together to form a new color consumable, thereby printing in various colors.

[0023] All colors are based on red (R), green (G) and blue (B) as the basic colors. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com