A plate feeding mechanism with a rotating rectifying mechanism

A technology of supplying plates and rotating sleeves, applied in the direction of object supply, flipping objects, positioning objects, etc., can solve the problems of easy deviation, large limitations, and poor placement effect, so as to ensure the patch effect and correct the deviation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] For ease of description and understanding, the "X direction" in this embodiment and the claims is parallel to the feeding direction of the board feeding mechanism, the "Y direction" is on the same plane as the board feeding mechanism and perpendicular to its feeding direction, and the Z direction is vertical On the plane where the plate supply mechanism is located.

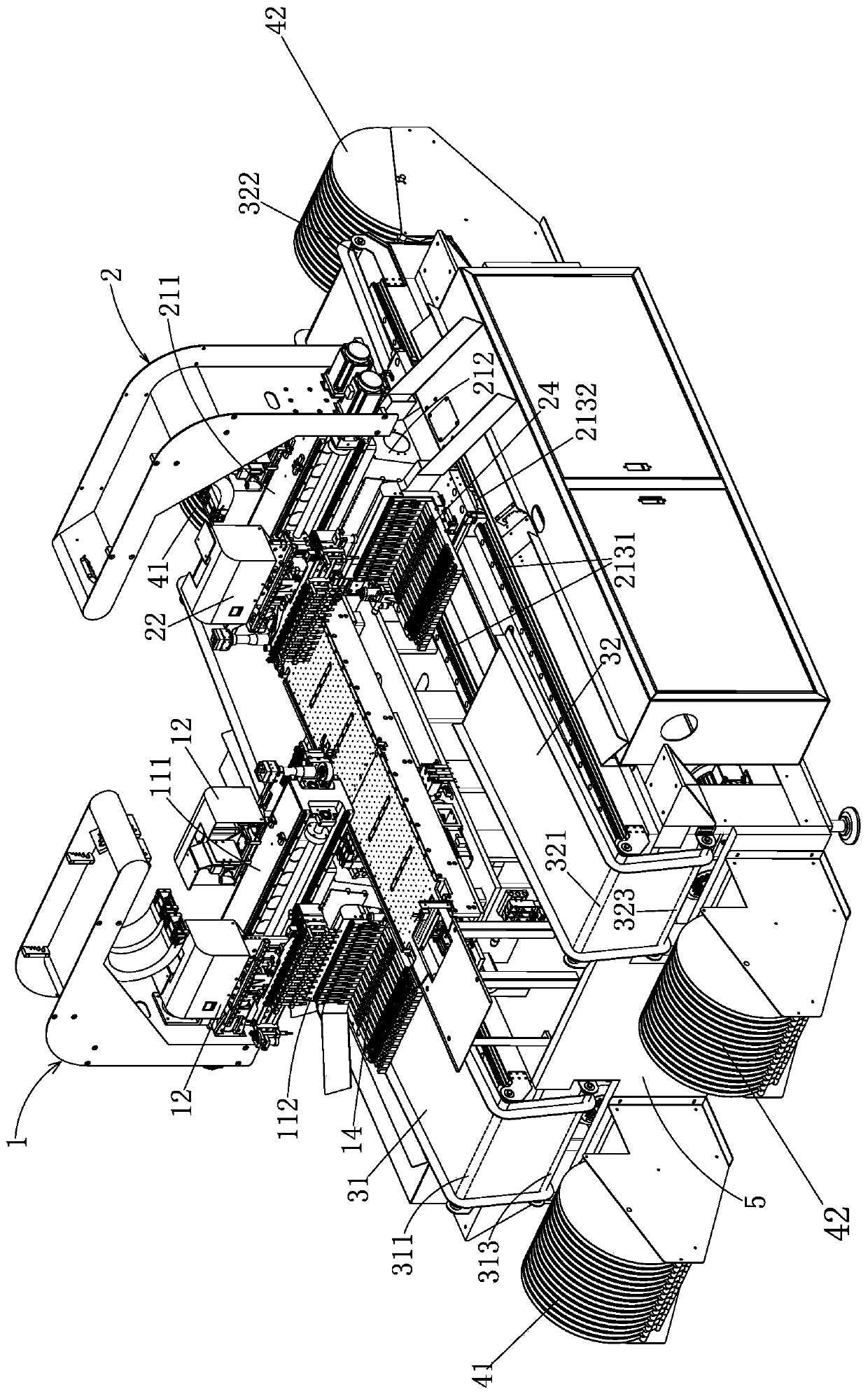

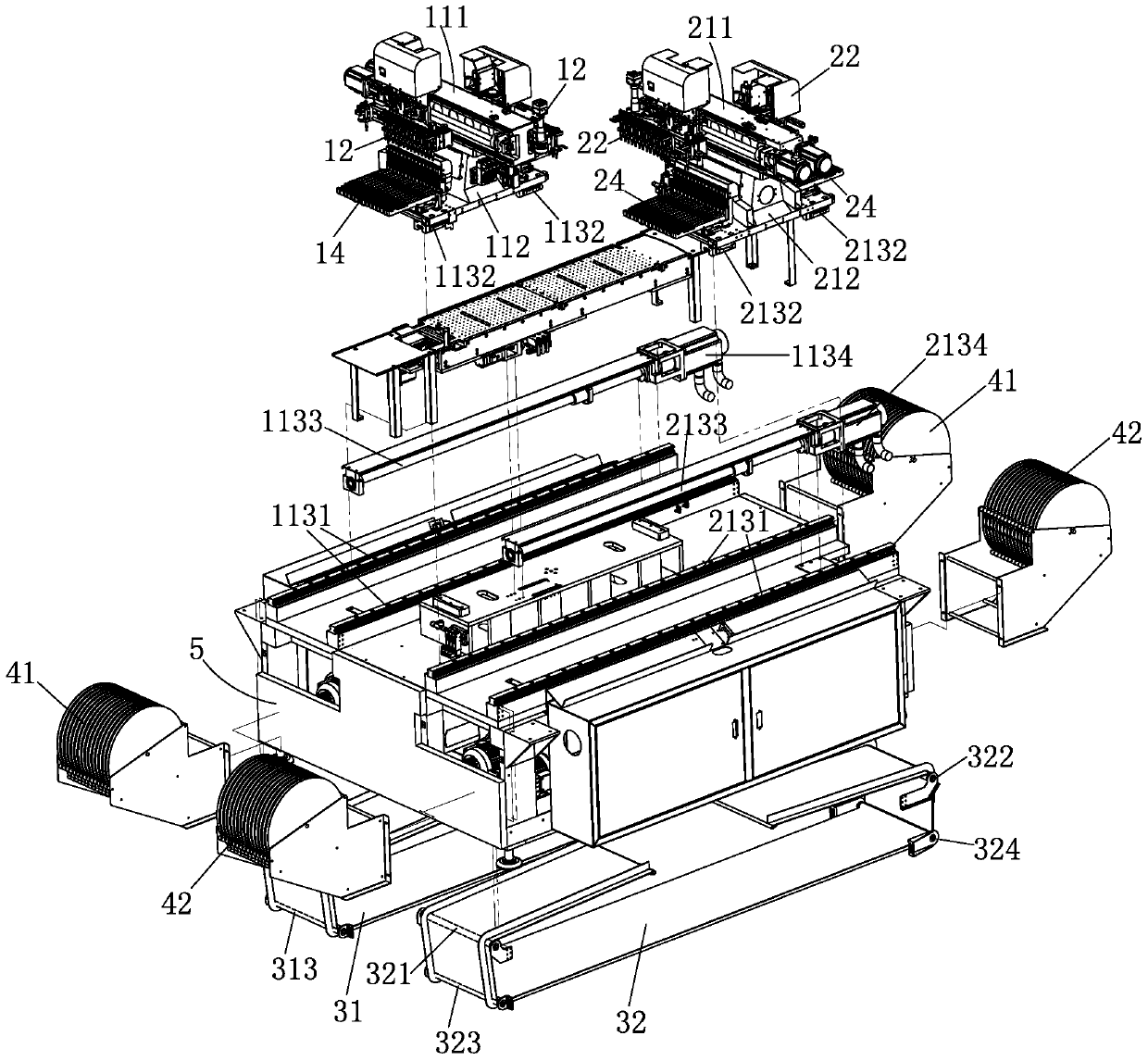

[0035] see figure 1 with figure 2 The three-dimensional view and the exploded view of the flexible circuit board placement machine of this embodiment, the flexible circuit board placement machine includes a board supply mechanism for supplying flexible circuit boards, four tray groups 41, 42, and respectively on both sides of the board supply mechanism along X Two sets of translation mounting mechanisms 1,2 moving to the direction, plate feeding mechanism, material tray group 42,42 and translation mounting mechanism 1,2 are all arranged on the frame 5.

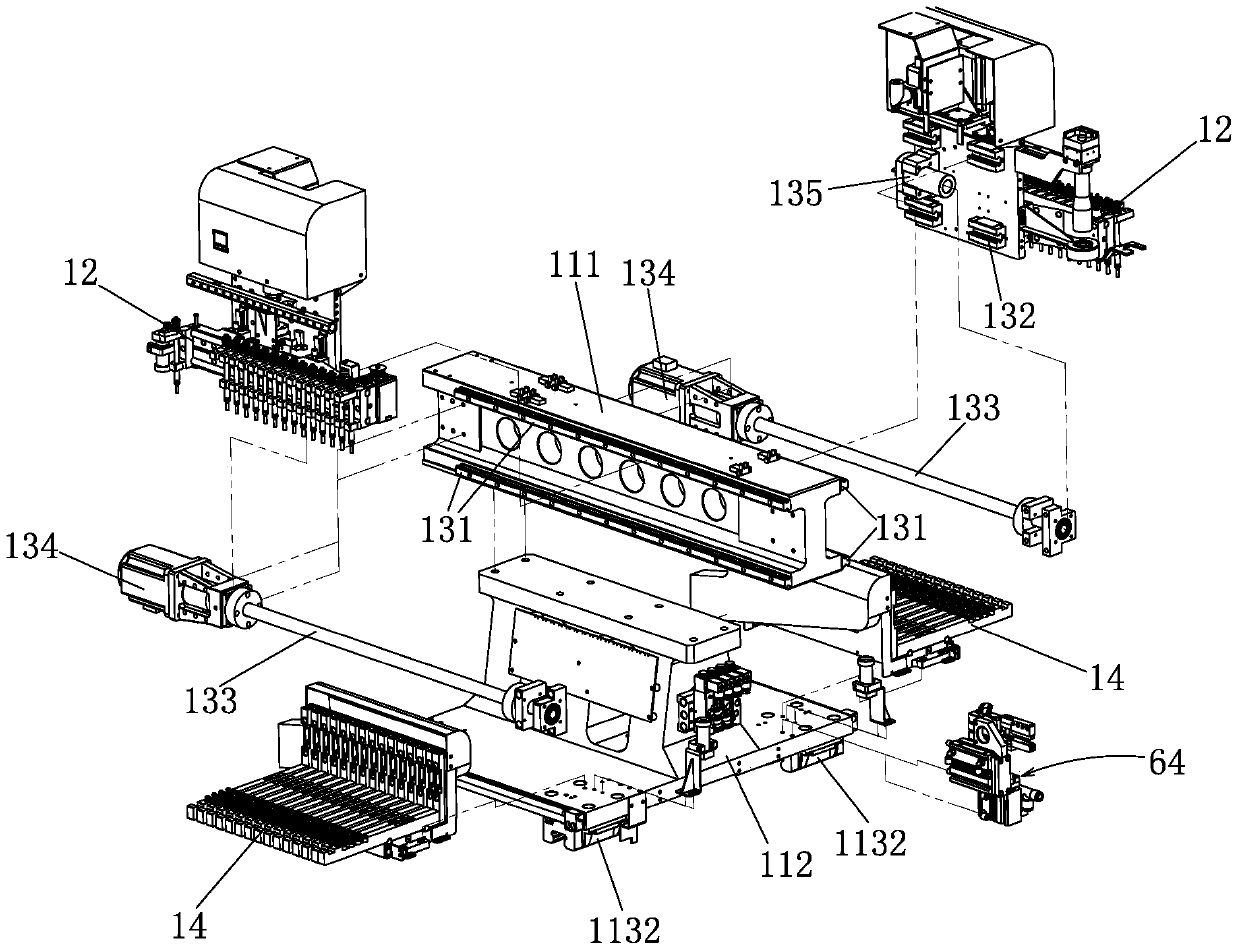

[0036] see image 3Each set of translation patch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com