Self-heating sheet electric warming wall and manufacturing method thereof

A self-heating, thin plate technology, applied in the field of electric heating wall, can solve the problems of changing the preparation technology, unsightly electric heating plate, low heat conversion rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

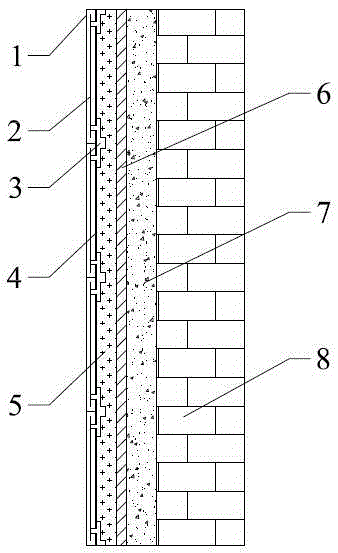

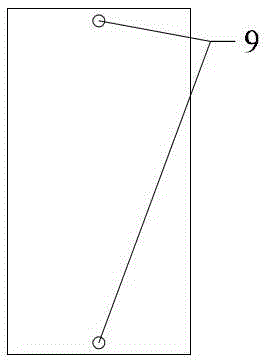

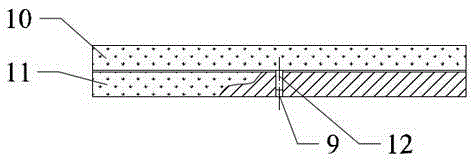

[0030] Such as Figure 1-7 As mentioned above, a self-heating thin plate electric heating wall includes a base and a group of heat generating thin plate layers 1 arranged on the base. The heat-generating thin plate layer 1 includes a thin plate front plate 10 , a thin plate back plate 11 , and a carbon fiber paper layer 2 arranged between the thin plate front plate 10 and the thin plate back plate 11 . The veneer front panel 10 and the veneer back panel 11 are sliced, rotary cut and sawn wood, bamboo veneer or sliced recombined wood veneer, recombined bamboo veneer. The carbon fiber paper layer 2 is made of carbon fiber paper, and the upper and lower ends of the carbon fiber paper are provided with metal conductive strips, and the middle part of the metal conductive strip has a hole, and the connector mother part 12 is arranged on the opening. The upper and lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com