Belt conveyor corridor system

A belt conveyor and corridor technology, which is applied to industrial buildings, buildings, building structures, etc., can solve the problem of inability to take into account the optimization design of belt conveyor corridor system structure and the optimization of processing technology, so as to optimize the belt conveyor corridor system structure. , to ensure the optimization needs, to ensure the effect of the processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention can have various changes in different embodiments without departing from the scope of the present invention, and that the descriptions and illustrations therein are illustrative in nature and not intended to limit the present invention. invention.

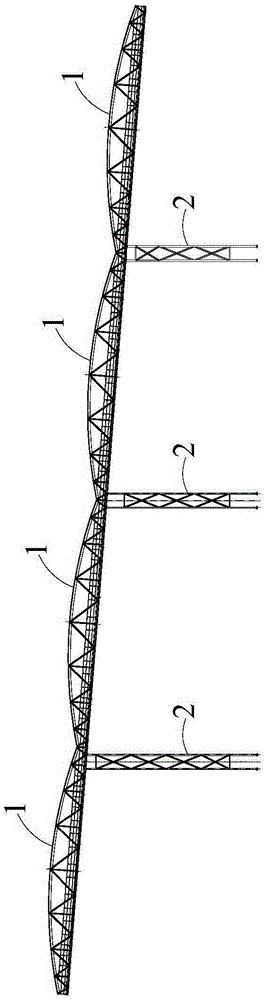

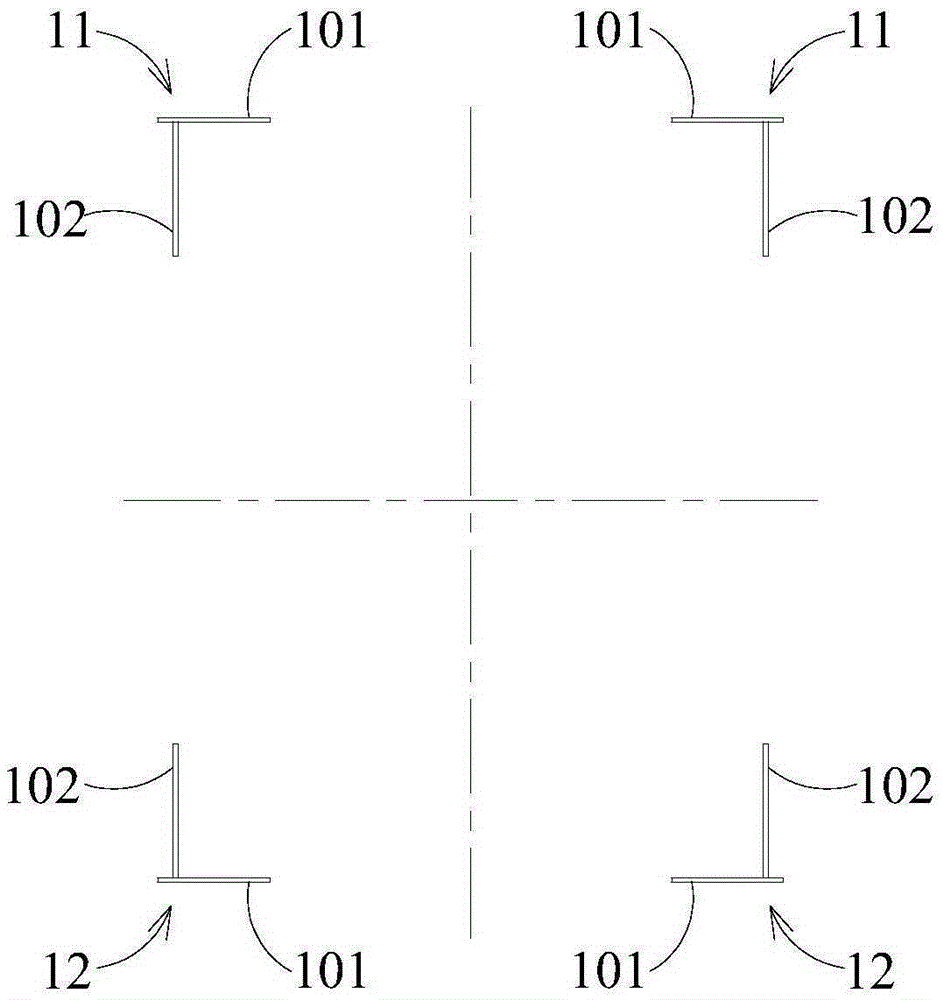

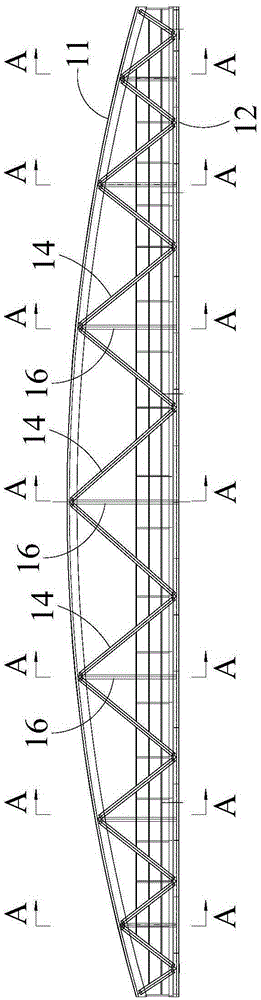

[0036] Such as figure 1 As shown, an embodiment of the belt conveyor corridor system proposed by the present invention. The belt conveyor corridor system can be used to carry a transmission mechanism such as a belt conveyor. Specifically, in this embodiment, the belt conveyor corridor system mainly includes a plurality of corridors 1 and a plurality of columns 2 . A plurality of corridors 1 are connected in sequence to carry the belt conveyor, and these corridors 1 are combined with a fish-belly beam structure and a truss structure to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com