Spray nozzle assembly

A technology of nozzles and components, applied to engine components, fuel injection devices, mechanical equipment, etc., to achieve good heat exchange, clear flow direction, and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

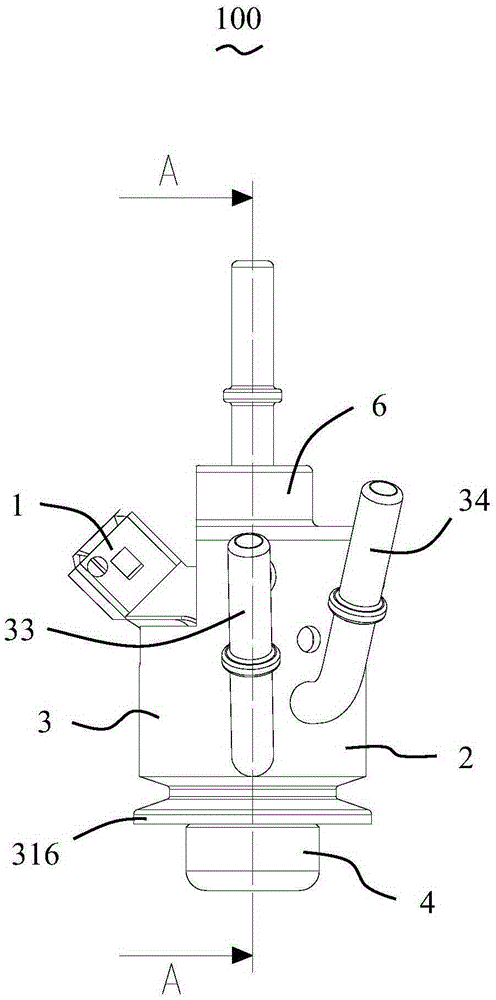

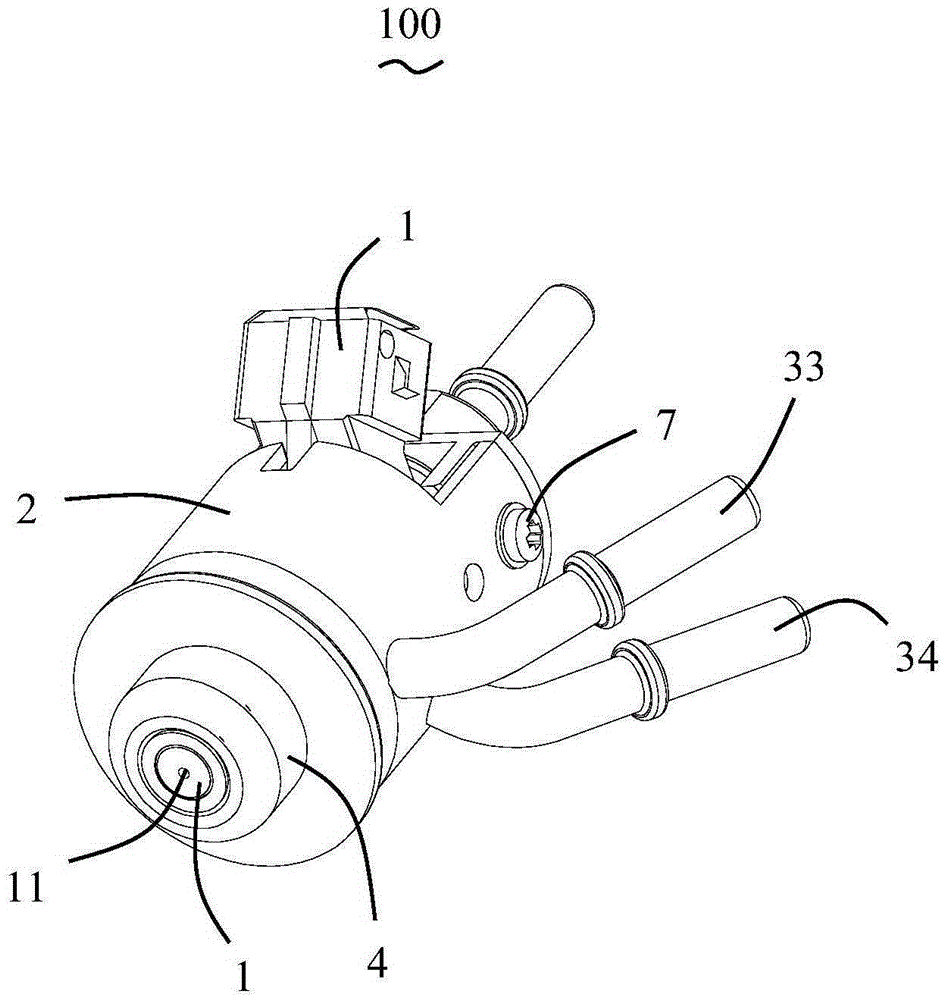

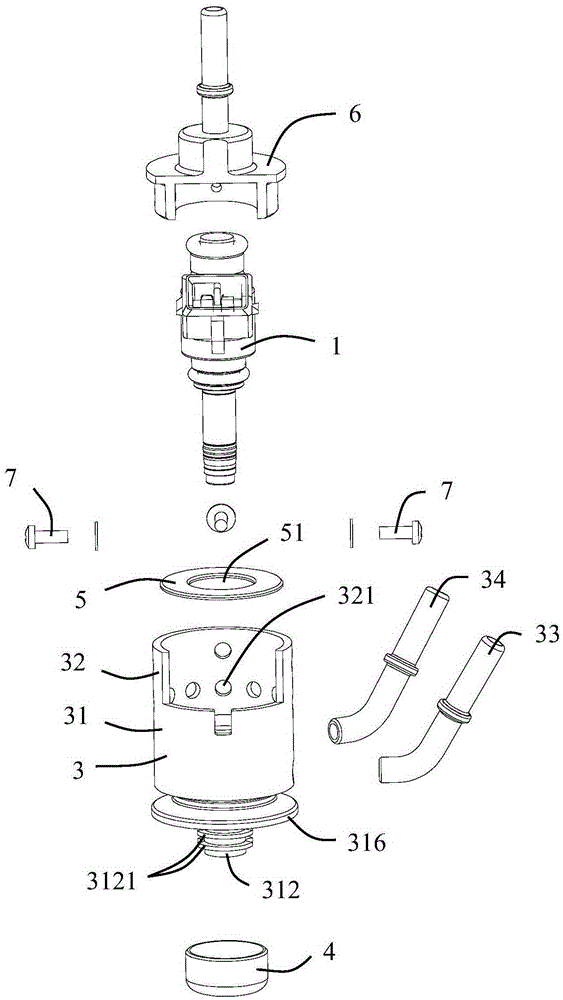

[0032] Please refer to Figure 1 to Figure 9 As shown, the present invention discloses a nozzle assembly 100 , which includes a nozzle 1 and a cooling jacket 2 surrounding the nozzle 1 . The nozzle 1 may be a urea nozzle or a fuel nozzle. The nozzle 1 includes a magnetic coil, a movable valve core, a valve seat matched with the valve core, and the like. The valve seat is provided with injection holes 11 . Since the structure of the nozzle 1 can be known by those skilled in the technical field, for example, reference can be made to the Chinese invention patent with the publication number CN102108891B, which will not be repeated here.

[0033] The cooling jacket 2 includes a cooling seat 3 , an end cover 4 located at the lower end of the cooling seat 3 , a sealing plate 5 fixed in the cooling seat 3 , and a cover 6 connected to the upper end of the cooling seat 3 .

[0034] Please refer to Figure 3 to Figure 7 As shown, the cooling base 3 includes a body portion 31 , a cyli...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap