O-shaped sealing ring packing bonding method and special tool

An O-ring and special tool technology, applied in mechanical equipment, connecting components, etc., can solve the problems of difficult operation, poor bonding effect, long time, etc., to reduce the difficulty of operation, improve the bonding effect, and prolong the use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

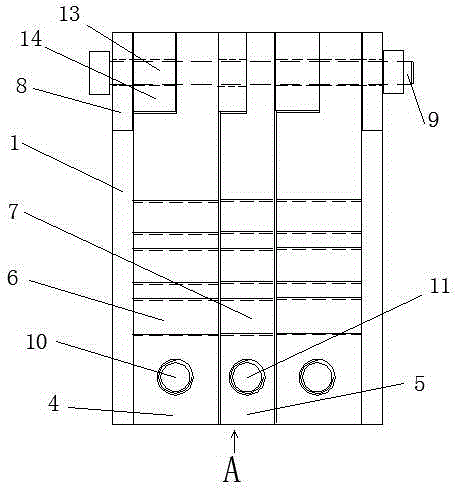

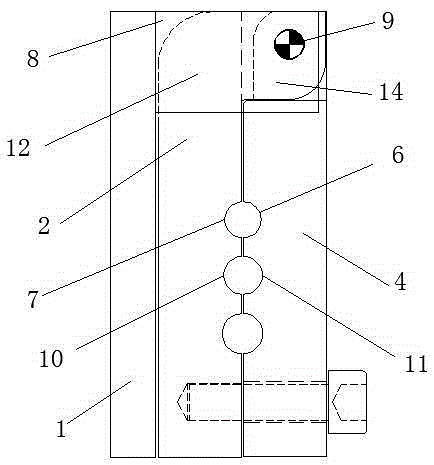

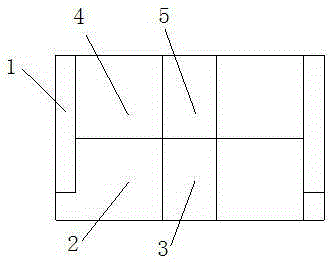

[0017] Example. An O-ring packing bonding method, which is bonded by an upper fixed pressing block, a lower fixed pressing block, an upper pressing block and a lower pressing block; the O-ring packing to be bonded is placed in the lower In the first packing groove set on the fixed pressure block, place the packing head on the third packing groove set in the middle of the lower pressure block, and press the second packing groove set on the upper fixed pressure block on the lower fixed pressure block. Connect and fix the upper and lower fixed pressure blocks on the first packing groove of The provided fourth packing groove presses on the third packing groove provided on the lower pressing block and clamps the part to be bonded.

[0018] The upper fixed pressure block includes two left and righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com