Transmission shaft for automobile

A technology for transmission shafts and vehicles, applied in the directions of shafts, couplings, shafts and bearings, etc., can solve the difficulty of connecting the composite material pipe body and the metal joint, the extrusion damage at the opening, and the inability of the metal transmission shaft to interact with each other. Replacement and other issues, to achieve better weight loss effect, mature preparation method, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Design and preparation technology of the present invention are described in further detail below by embodiment

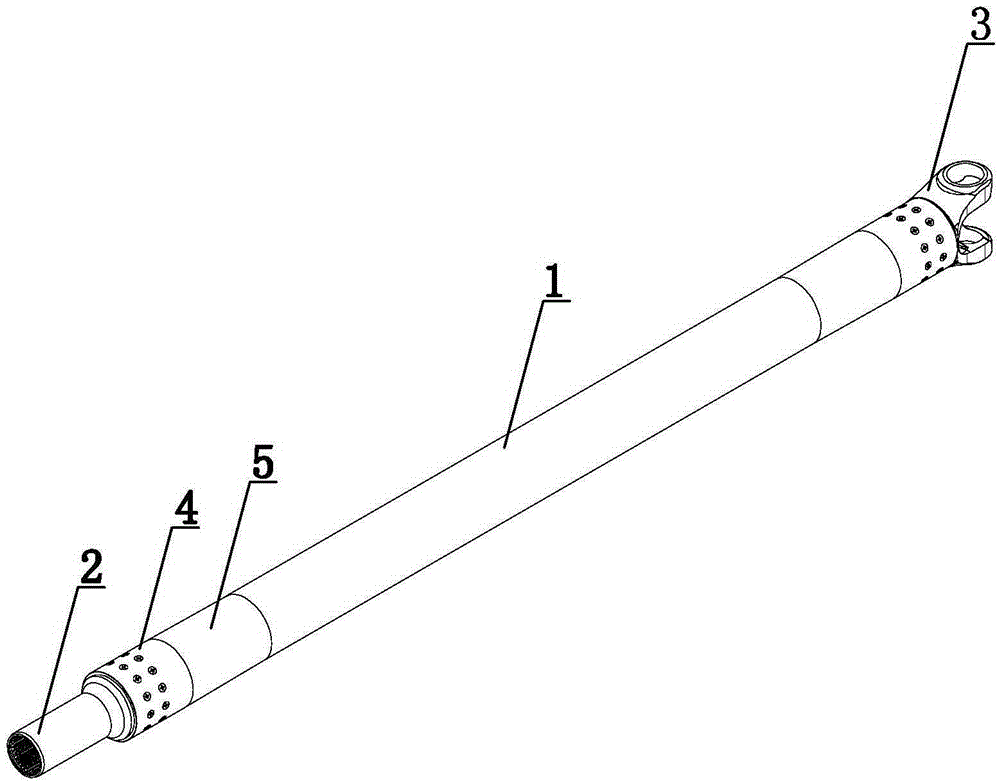

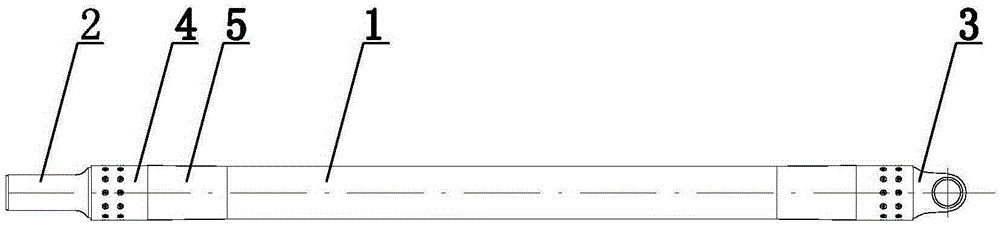

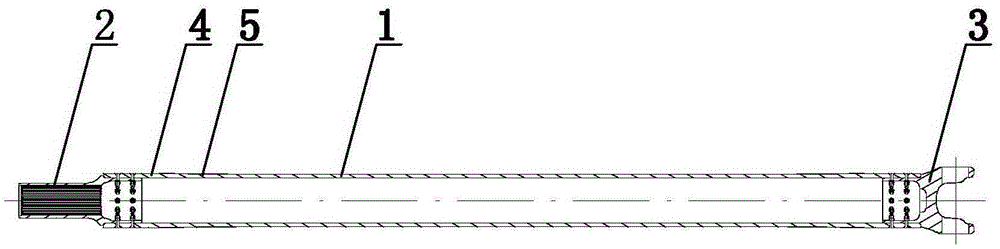

[0031] In this embodiment, a transmission shaft for a vehicle is combined with figure 1 , figure 2 and image 3 , consisting of a pipe body 1, a splined sleeve 2 and a universal joint fork 3, the splined sleeve 2 and the universal joint fork 3 are respectively arranged at both ends of the pipe body 1, and the pipe body 1 and the splined sleeve 2, A slope transition area 4 is set between the pipe body 1 and the universal joint fork 3, and the slope transition area 4 is integrated with the pipe body 1; Figure 4 , The pipe body 1 and the spline sleeve 2, the pipe body 1 and the universal joint fork 3 are fixed by the cooperation of the countersunk bolt 6 and the self-locking nut 7 .

[0032] which, combined with Figure 5 , the pipe body 1 is a layered structure formed by laying layers 13 at different angles. The laying layers 13 are laid symmetrically alo...

Embodiment 2

[0047] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that:

[0048] combine figure 1 , figure 2 and image 3 , consisting of a pipe body 1, a splined sleeve 2 and a universal joint fork 3, the splined sleeve 2 and the universal joint fork 3 are respectively arranged at both ends of the pipe body 1, and the pipe body 1 and the splined sleeve 2, A slope transition area 4 is set between the pipe body 1 and the universal joint fork 3, and the pipe body 1 is provided with a thick placement area 5 near the slope transition area 4, which is used to strengthen the strength of the connection part, and the slope transition area 4 , the thick placement area 5 and the pipe body 1 are of an integrated structure; combined Figure 4 , The pipe body 1 and the spline sleeve 2, the pipe body 1 and the universal joint fork 3 are fixed by the cooperation of the countersunk bolt 6 and the self-locking nut 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com