Method for detecting undesirable elastic force or drawing force of keycap of keyboard

A detection method and drawing force technology, applied in the field of detection, can solve the problems of high misjudgment rate, damage to good products, and high cost, and achieve the effect of high degree of automation, low detection cost, and no damage to good products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

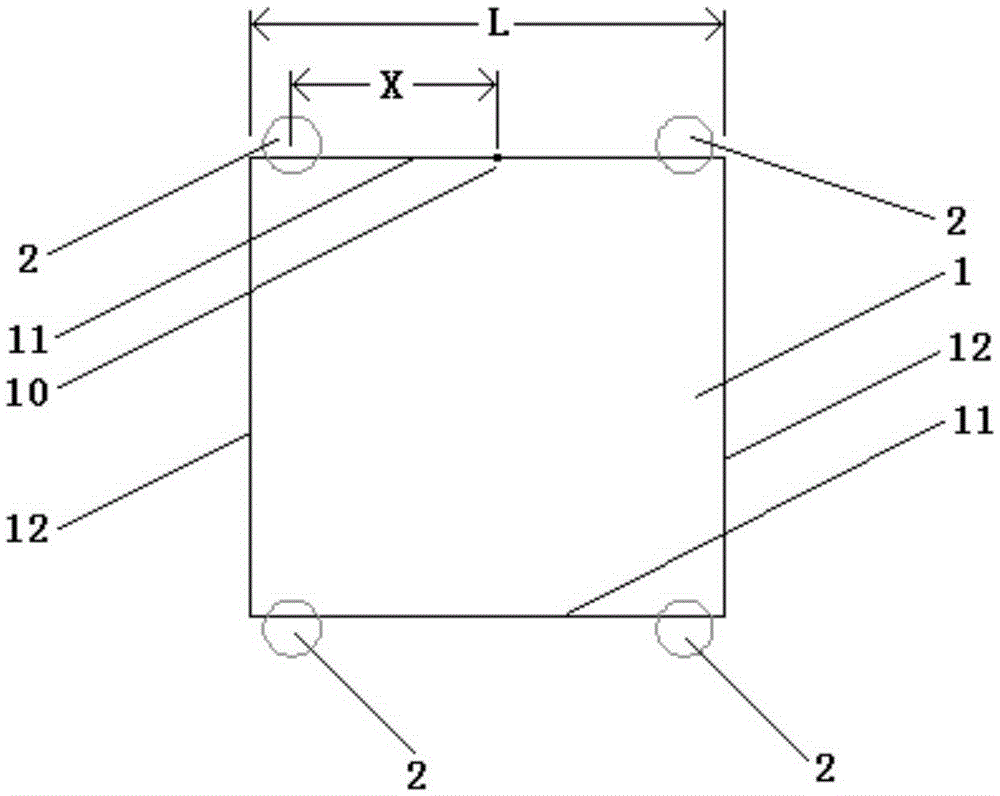

[0028] Below in conjunction with accompanying drawing of description, the present invention will be further described.

[0029] The present invention provides a detection method for detecting the bad elasticity or pulling force of keyboard keycaps, which utilizes the principle that each keycap edge of the keyboard has its fixed upward pulling force corresponding to the stroke, and specifically includes the following steps:

[0030] 1) Press the keyboard to be tested with the pressing mechanism to make the keyboard stable.

[0031] 2) Use a load cell with a hook at the bottom to hang a keycap in the keyboard to be tested for contact detection. The hook of the load cell directly acts on any side edge of the keycap or acts on any adjacent keycap. The intersection angle of the side edges. Preferably, several load cells are arranged side by side in rows to detect any row of key caps distributed horizontally in the keyboard at the same time, and each load cell is individually hooke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com