Processing technology for reducing sulfur content of light aromatic hydrocarbon

A technology of processing technology and sulfur content, which is applied in the fields of hydrogenation treatment process, petroleum industry, and hydrocarbon oil treatment, etc. It can solve the problems of substandard sulfur content of hydrogenation products, low product value, single product, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

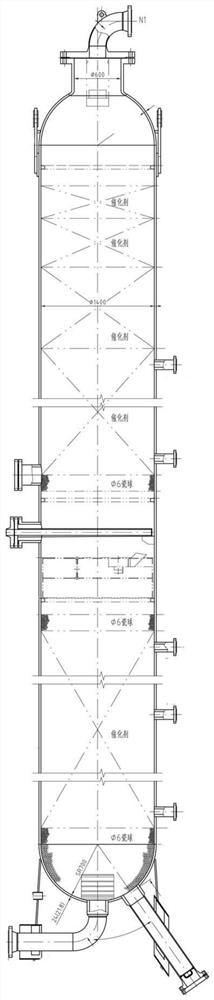

[0014] like figure 1 Shown, a kind of processing technology that reduces light aromatic hydrocarbon sulfur content comprises the steps:

[0015] a. Add a pre-hydrogenation reactor to saturate the light sulfur in the raw material into heavy sulfur components and diolefins, modify the flow of the original hydrogenation unit, and realize the hydrogenation of the whole distillate;

[0016] b. Expand capacity and increase pressure, optimize the original heat exchange and hydrogenation process, increase the design pressure of pre-hydrogenation and main hydrogenation equipment, and eliminate pressure-bearing bottlenecks;

[0017] c. The feed is filtered by a filter to remove solid particles, preventing the reactor from being blocked by solid particles in the inlet and causing excessive pressure drop, and ensuring long-term stable operation of the device;

[0018] d. There are two catalyst beds in the selective hydrogenation reactor, and quenched hydrogen is injected between the beds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com