Non-casting steel wire rope tensile test clamping device

A clamping device and tensile test technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of wire rope breaking and other problems, achieve the effects of reducing labor intensity, optimizing the test process, and reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

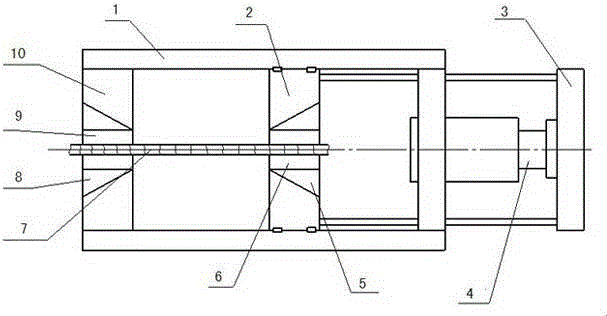

[0012] A kind of non-cast steel wire rope tensile test clamping device of the present invention is described in further detail below in conjunction with accompanying drawing:

[0013] figure 1 Among them, it consists of a frame 1, a front clamping device 2, a moving beam 3, a force measuring device 4, a clip seat 5, a clip 6, a clip seat 8, a clip 9, and a rear clamping device 10; the front clip The clamping device 2 and the rear clamping device 10 are arranged on the frame 1, the front clamping device 2 is provided with a clip seat 5 and a clip 6, and the rear clamping device 10 is provided with a clip seat 8 and a clip 9, and the frame 1 is provided with a moving beam 3 and a force measuring device 4.

[0014] The clamping device adopts the form of hydraulic clamping and loosening, and the clamping force is 5-15Mpa, which is adjustable;

[0015] The openings of the clips 6 and 9 are V-shaped, increasing the contact surface with the wire rope 7;

[0016] The surfaces of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com