Method for measuring kinematic viscosity of lubricating oil in pipeline through remote sensing

A technology of kinematic viscosity and lubricating oil, which is applied in the direction of flow characteristics, measuring devices, instruments, etc., can solve the problems of too large volume, the inability to determine the kinematic viscosity value of lubricating oil, and the inconvenience of monitoring the kinematic viscosity of lubricating oil on site, so as to improve efficiency, Improved measurement efficiency and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

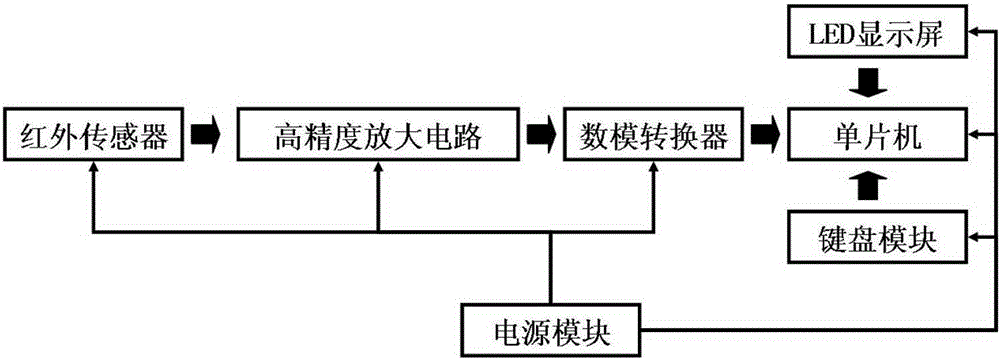

Image

Examples

Embodiment 1

[0020] Obtain the viscosity-temperature curve equation of the tested oil product "Great Wall TSA32 Turbine Oil" from the supplier:

[0021] y=303.1×0.9163 x +15.95

[0022] Among them, y is the kinematic viscosity value of the oil, mm 2 / s; x is the temperature of the oil product, °C.

[0023] Select the oil brand used by the equipment: Great Wall TSA32 Turbine Oil. Aim the infrared sensor of the device at the pipeline to be tested. There is running TSA32 turbine oil in the pipeline. Since the pipeline is a metal tube, its temperature can be approximately regarded as the oil temperature of the turbine oil. After data processing by the device, it can be obtained: the current temperature is 56°C, and the corresponding kinematic viscosity is 18.22mm 2 / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com