One-time bunch strand normal molding method and apparatus

A molding device, a one-time technology, applied in the manufacturing of electrical components, circuits, cables/conductors, etc., can solve the problems of slow speed, complicated processes, and unfavorable rapid production of automobile wire conductors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

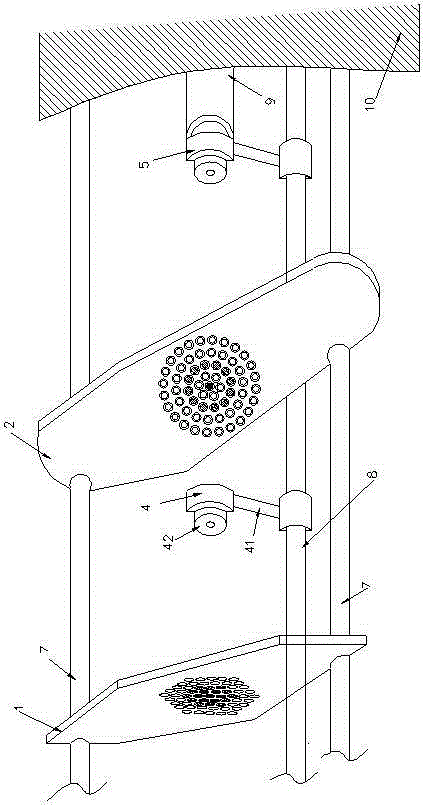

[0035] like figure 1 , image 3 , Figure 5 As shown, the one-time stranding normal forming device includes two parallel branch board support guide rods and a mold base support guide rod; the two parallel branch board support guide rods are provided with a first branch Line board, second branch board; between the first branch board and the second branch board, the first twisted wire mold is provided on the mold base support guide rod; the mold base supports the guide rod There is a second stranded wire mold at the tail.

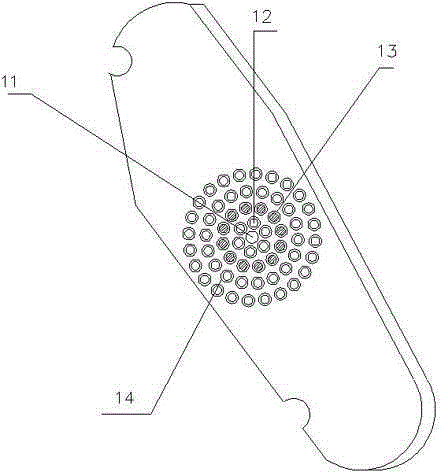

[0036] The distribution board is provided with multi-layer threading holes, the central layer is a single hole, the second layer has 6 holes, and the third layer has 12 holes. The supporting guide rods of the mold holders are located below the two parallel supporting guide rods of the distribution boards; the stranding molds include stranding mold bases and stranding molds.

[0037] The method of regular forming of one-time beam stranding, the specific st...

Embodiment 2

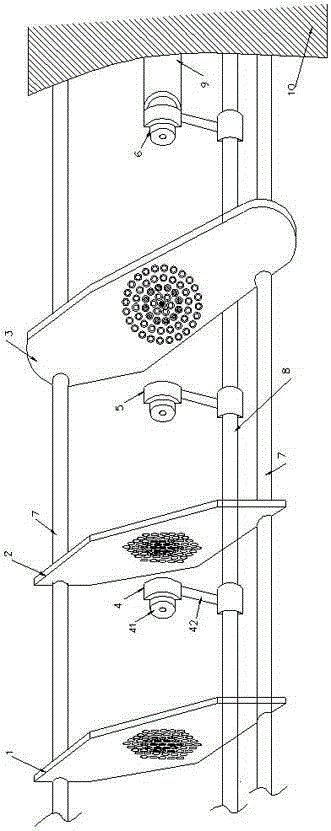

[0044] like figure 2 , image 3 , as shown in Figure 6, the disposable beam stranded regular forming device comprises two parallel branch board support guide rods and a mold seat support guide rod; the two parallel branch board support guide rods are provided with The first distribution board, the second distribution board, and the third distribution board; between the first distribution board and the second distribution board, a first Stranded wire mould; between the second branching plate and the third branching plate, a second stranding mold is provided on the mold seat support guide rod; the tail of the mold seat support guide rod is provided with The third strand die.

[0045] The distribution board is provided with multi-layer threading holes, the central layer is a single hole, the second layer has 6 holes, the third layer has 12 holes, and the fourth layer has 18 holes. The supporting guide rods of the mold holders are located below the two parallel supporting guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com